PDF Publication Title:

Text from PDF Page: 003

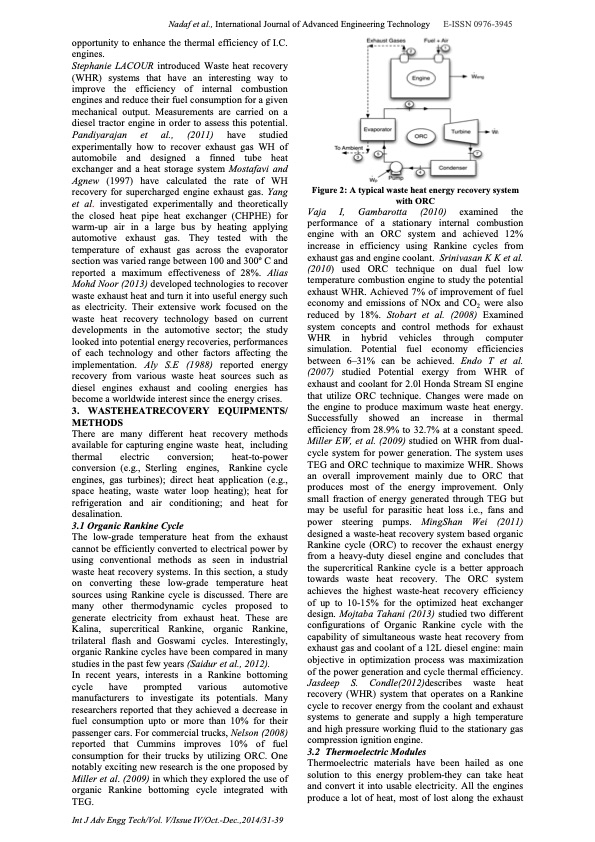

Nadaf et al., International Journal of Advanced Engineering Technology E-ISSN 0976-3945 opportunity to enhance the thermal efficiency of I.C. engines. Stephanie LACOUR introduced Waste heat recovery (WHR) systems that have an interesting way to improve the efficiency of internal combustion engines and reduce their fuel consumption for a given mechanical output. Measurements are carried on a diesel tractor engine in order to assess this potential. Pandiyarajan et al., (2011) have studied experimentally how to recover exhaust gas WH of automobile and designed a finned tube heat exchanger and a heat storage system Mostafavi and Agnew (1997) have calculated the rate of WH recovery for supercharged engine exhaust gas. Yang et al. investigated experimentally and theoretically the closed heat pipe heat exchanger (CHPHE) for warm-up air in a large bus by heating applying automotive exhaust gas. They tested with the temperature of exhaust gas across the evaporator section was varied range between 100 and 300o C and reported a maximum effectiveness of 28%. Alias Mohd Noor (2013) developed technologies to recover waste exhaust heat and turn it into useful energy such as electricity. Their extensive work focused on the waste heat recovery technology based on current developments in the automotive sector; the study looked into potential energy recoveries, performances of each technology and other factors affecting the implementation. Aly S.E (1988) reported energy recovery from various waste heat sources such as diesel engines exhaust and cooling energies has become a worldwide interest since the energy crises. 3. WASTEHEATRECOVERY EQUIPMENTS/ METHODS There are many different heat recovery methods available for capturing engine waste heat, including thermal electric conversion; heat-to-power conversion (e.g., Sterling engines, Rankine cycle engines, gas turbines); direct heat application (e.g., space heating, waste water loop heating); heat for refrigeration and air conditioning; and heat for desalination. 3.1 Organic Rankine Cycle The low-grade temperature heat from the exhaust cannot be efficiently converted to electrical power by using conventional methods as seen in industrial waste heat recovery systems. In this section, a study on converting these low-grade temperature heat sources using Rankine cycle is discussed. There are many other thermodynamic cycles proposed to generate electricity from exhaust heat. These are Kalina, supercritical Rankine, organic Rankine, trilateral flash and Goswami cycles. Interestingly, organic Rankine cycles have been compared in many studies in the past few years (Saidur et al., 2012). In recent years, interests in a Rankine bottoming cycle have prompted various automotive manufacturers to investigate its potentials. Many researchers reported that they achieved a decrease in fuel consumption upto or more than 10% for their passenger cars. For commercial trucks, Nelson (2008) reported that Cummins improves 10% of fuel consumption for their trucks by utilizing ORC. One notably exciting new research is the one proposed by Miller et al. (2009) in which they explored the use of organic Rankine bottoming cycle integrated with TEG. Figure 2: A typical waste heat energy recovery system with ORC Vaja I, Gambarotta (2010) examined the performance of a stationary internal combustion engine with an ORC system and achieved 12% increase in efficiency using Rankine cycles from exhaust gas and engine coolant. Srinivasan K K et al. (2010) used ORC technique on dual fuel low temperature combustion engine to study the potential exhaust WHR. Achieved 7% of improvement of fuel economy and emissions of NOx and CO2 were also reduced by 18%. Stobart et al. (2008) Examined system concepts and control methods for exhaust WHR in hybrid vehicles through computer simulation. Potential fuel economy efficiencies between 6–31% can be achieved. Endo T et al. (2007) studied Potential exergy from WHR of exhaust and coolant for 2.0l Honda Stream SI engine that utilize ORC technique. Changes were made on the engine to produce maximum waste heat energy. Successfully showed an increase in thermal efficiency from 28.9% to 32.7% at a constant speed. Miller EW, et al. (2009) studied on WHR from dual- cycle system for power generation. The system uses TEG and ORC technique to maximize WHR. Shows an overall improvement mainly due to ORC that produces most of the energy improvement. Only small fraction of energy generated through TEG but may be useful for parasitic heat loss i.e., fans and power steering pumps. MingShan Wei (2011) designed a waste-heat recovery system based organic Rankine cycle (ORC) to recover the exhaust energy from a heavy-duty diesel engine and concludes that the supercritical Rankine cycle is a better approach towards waste heat recovery. The ORC system achieves the highest waste-heat recovery efficiency of up to 10-15% for the optimized heat exchanger design. Mojtaba Tahani (2013) studied two different configurations of Organic Rankine cycle with the capability of simultaneous waste heat recovery from exhaust gas and coolant of a 12L diesel engine: main objective in optimization process was maximization of the power generation and cycle thermal efficiency. Jasdeep S. Condle(2012)describes waste heat recovery (WHR) system that operates on a Rankine cycle to recover energy from the coolant and exhaust systems to generate and supply a high temperature and high pressure working fluid to the stationary gas compression ignition engine. 3.2 Thermoelectric Modules Thermoelectric materials have been hailed as one solution to this energy problem-they can take heat and convert it into usable electricity. All the engines produce a lot of heat, most of lost along the exhaust Int J Adv Engg Tech/Vol. V/Issue IV/Oct.-Dec.,2014/31-39PDF Image | REVIEW ON WASTE HEAT RECOVERY FROM DIESEL ENGINES

PDF Search Title:

REVIEW ON WASTE HEAT RECOVERY FROM DIESEL ENGINESOriginal File Name Searched:

Vol_V_Issue_IV_Article_7.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |