PDF Publication Title:

Text from PDF Page: 002

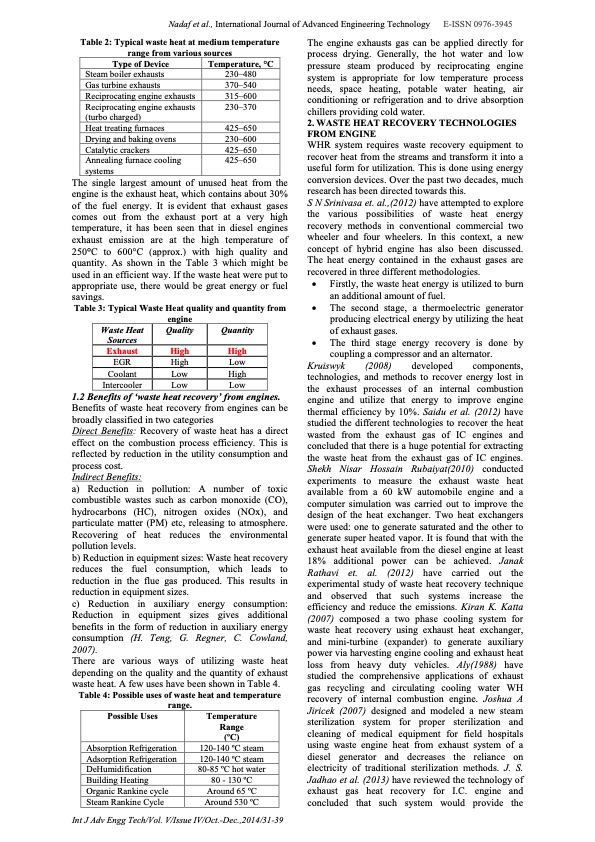

Nadaf et al., International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Table 2: Typical waste heat at medium temperature range from various sources The engine exhausts gas can be applied directly for process drying. Generally, the hot water and low pressure steam produced by reciprocating engine system is appropriate for low temperature process needs, space heating, potable water heating, air conditioning or refrigeration and to drive absorption chillers providing cold water. 2. WASTE HEAT RECOVERY TECHNOLOGIES FROM ENGINE WHR system requires waste recovery equipment to recover heat from the streams and transform it into a useful form for utilization. This is done using energy conversion devices. Over the past two decades, much research has been directed towards this. S N Srinivasa et. al.,(2012) have attempted to explore the various possibilities of waste heat energy recovery methods in conventional commercial two wheeler and four wheelers. In this context, a new concept of hybrid engine has also been discussed. The heat energy contained in the exhaust gases are recovered in three different methodologies. • Firstly, the waste heat energy is utilized to burn an additional amount of fuel. • The second stage, a thermoelectric generator producing electrical energy by utilizing the heat of exhaust gases. • The third stage energy recovery is done by coupling a compressor and an alternator. Kruiswyk (2008) developed components, technologies, and methods to recover energy lost in the exhaust processes of an internal combustion engine and utilize that energy to improve engine thermal efficiency by 10%. Saidu et al. (2012) have studied the different technologies to recover the heat wasted from the exhaust gas of IC engines and concluded that there is a huge potential for extracting the waste heat from the exhaust gas of IC engines. Shekh Nisar Hossain Rubaiyat(2010) conducted experiments to measure the exhaust waste heat available from a 60 kW automobile engine and a computer simulation was carried out to improve the design of the heat exchanger. Two heat exchangers were used: one to generate saturated and the other to generate super heated vapor. It is found that with the exhaust heat available from the diesel engine at least 18% additional power can be achieved. Janak Rathavi et. al. (2012) have carried out the experimental study of waste heat recovery technique and observed that such systems increase the efficiency and reduce the emissions. Kiran K. Katta (2007) composed a two phase cooling system for waste heat recovery using exhaust heat exchanger, and mini-turbine (expander) to generate auxiliary power via harvesting engine cooling and exhaust heat loss from heavy duty vehicles. Aly(1988) have studied the comprehensive applications of exhaust gas recycling and circulating cooling water WH recovery of internal combustion engine. Joshua A Jiricek (2007) designed and modeled a new steam sterilization system for proper sterilization and cleaning of medical equipment for field hospitals using waste engine heat from exhaust system of a diesel generator and decreases the reliance on electricity of traditional sterilization methods. J. S. Jadhao et al. (2013) have reviewed the technology of exhaust gas heat recovery for I.C. engine and concluded that such system would provide the Type of Device Steam boiler exhausts Gas turbine exhausts Reciprocating engine exhausts Reciprocating engine exhausts (turbo charged) Heat treating furnaces Drying and baking ovens Catalytic crackers Annealing furnace cooling systems Temperature, °C 230–480 370–540 315–600 230–370 425–650 230–600 425–650 425–650 The single largest amount of unused heat from the engine is the exhaust heat, which contains about 30% of the fuel energy. It is evident that exhaust gases comes out from the exhaust port at a very high temperature, it has been seen that in diesel engines exhaust emission are at the high temperature of 250°C to 600°C (approx.) with high quality and quantity. As shown in the Table 3 which might be used in an efficient way. If the waste heat were put to appropriate use, there would be great energy or fuel savings. Table 3: Typical Waste Heat quality and quantity from engine Waste Heat Quality Sources Exhaust High High EGR High Low Coolant Low High Intercooler Low Low 1.2 Benefits of ‘waste heat recovery’ from engines. Benefits of waste heat recovery from engines can be broadly classified in two categories Direct Benefits: Recovery of waste heat has a direct effect on the combustion process efficiency. This is reflected by reduction in the utility consumption and process cost. Indirect Benefits: a) Reduction in pollution: A number of toxic combustible wastes such as carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and particulate matter (PM) etc, releasing to atmosphere. Recovering of heat reduces the environmental pollution levels. b) Reduction in equipment sizes: Waste heat recovery reduces the fuel consumption, which leads to reduction in the flue gas produced. This results in reduction in equipment sizes. c) Reduction in auxiliary energy consumption: Reduction in equipment sizes gives additional benefits in the form of reduction in auxiliary energy consumption (H. Teng, G. Regner, C. Cowland, 2007). There are various ways of utilizing waste heat depending on the quality and the quantity of exhaust waste heat. A few uses have been shown in Table 4. Table 4: Possible uses of waste heat and temperature range. Quantity Possible Uses Absorption Refrigeration Adsorption Refrigeration DeHumidification Building Heating Organic Rankine cycle Steam Rankine Cycle Temperature Range (oC) 120-140 oC steam 120-140 oC steam 80-85 oC hot water 80 - 130 oC Around 65 oC Around 530 oC Int J Adv Engg Tech/Vol. V/Issue IV/Oct.-Dec.,2014/31-39PDF Image | REVIEW ON WASTE HEAT RECOVERY FROM DIESEL ENGINES

PDF Search Title:

REVIEW ON WASTE HEAT RECOVERY FROM DIESEL ENGINESOriginal File Name Searched:

Vol_V_Issue_IV_Article_7.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |