PDF Publication Title:

Text from PDF Page: 002

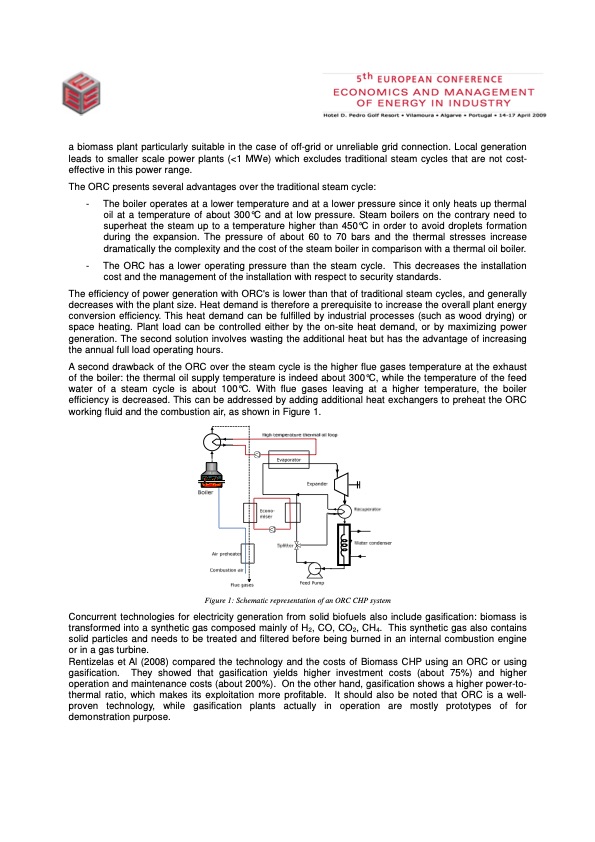

a biomass plant particularly suitable in the case of off-grid or unreliable grid connection. Local generation leads to smaller scale power plants (<1 MWe) which excludes traditional steam cycles that are not cost- effective in this power range. The ORC presents several advantages over the traditional steam cycle: - The boiler operates at a lower temperature and at a lower pressure since it only heats up thermal oil at a temperature of about 300°C and at low pressure. Steam boilers on the contrary need to superheat the steam up to a temperature higher than 450°C in order to avoid droplets formation during the expansion. The pressure of about 60 to 70 bars and the thermal stresses increase dramatically the complexity and the cost of the steam boiler in comparison with a thermal oil boiler. - The ORC has a lower operating pressure than the steam cycle. This decreases the installation cost and the management of the installation with respect to security standards. The efficiency of power generation with ORC's is lower than that of traditional steam cycles, and generally decreases with the plant size. Heat demand is therefore a prerequisite to increase the overall plant energy conversion efficiency. This heat demand can be fulfilled by industrial processes (such as wood drying) or space heating. Plant load can be controlled either by the on-site heat demand, or by maximizing power generation. The second solution involves wasting the additional heat but has the advantage of increasing the annual full load operating hours. A second drawback of the ORC over the steam cycle is the higher flue gases temperature at the exhaust of the boiler: the thermal oil supply temperature is indeed about 300°C, while the temperature of the feed water of a steam cycle is about 100°C. With flue gases leaving at a higher temperature, the boiler efficiency is decreased. This can be addressed by adding additional heat exchangers to preheat the ORC working fluid and the combustion air, as shown in Figure 1. Figure 1: Schematic representation of an ORC CHP system Concurrent technologies for electricity generation from solid biofuels also include gasification: biomass is transformed into a synthetic gas composed mainly of H2, CO, CO2, CH4. This synthetic gas also contains solid particles and needs to be treated and filtered before being burned in an internal combustion engine or in a gas turbine. Rentizelas et Al (2008) compared the technology and the costs of Biomass CHP using an ORC or using gasification. They showed that gasification yields higher investment costs (about 75%) and higher operation and maintenance costs (about 200%). On the other hand, gasification shows a higher power-to- thermal ratio, which makes its exploitation more profitable. It should also be noted that ORC is a well- proven technology, while gasification plants actually in operation are mostly prototypes of for demonstration purpose.PDF Image | Technological and Economical Survey of Organic Rankine Cycle Systems

PDF Search Title:

Technological and Economical Survey of Organic Rankine Cycle SystemsOriginal File Name Searched:

Tech_and_Econ_Survey_of_ORC_Belgium_2009.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |