PDF Publication Title:

Text from PDF Page: 003

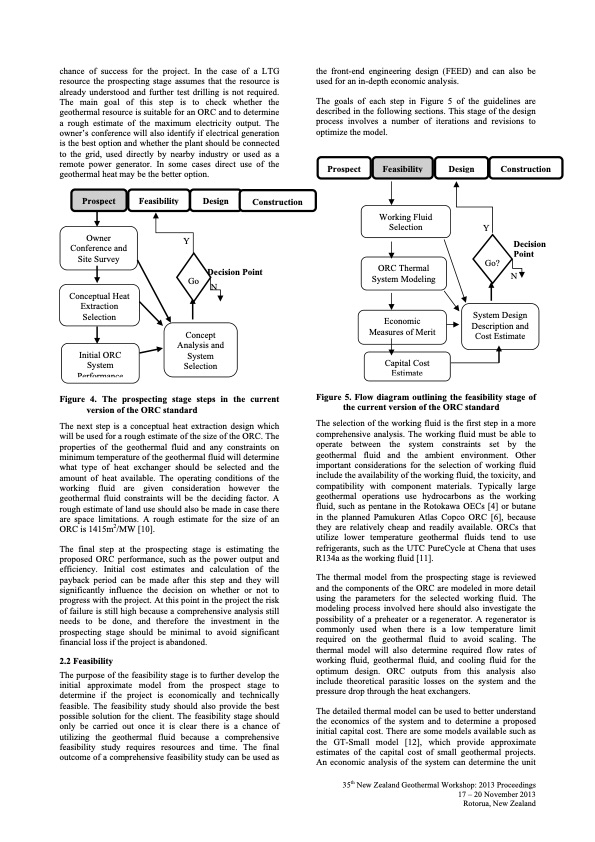

chance of success for the project. In the case of a LTG resource the prospecting stage assumes that the resource is already understood and further test drilling is not required. The main goal of this step is to check whether the geothermal resource is suitable for an ORC and to determine a rough estimate of the maximum electricity output. The owner’s conference will also identify if electrical generation is the best option and whether the plant should be connected to the grid, used directly by nearby industry or used as a remote power generator. In some cases direct use of the geothermal heat may be the better option. the front-end engineering design (FEED) and can also be used for an in-depth economic analysis. The goals of each step in Figure 5 of the guidelines are described in the following sections. This stage of the design process involves a number of iterations and revisions to optimize the model. Prospect Feasibility Working Fluid Selection ORC Thermal System Modeling Economic Measures of Merit Capital Cost Estimate Design Construction Decision Point Go? N Prospect Owner Conference and Site Survey Conceptual Heat Extraction Selection Initial ORC System Performance Feasibility Design Construction Y Y Go N Decision Point Concept Analysis and System Selection System Design Description and Cost Estimate Figure 4. The prospecting stage steps in the current version of the ORC standard The next step is a conceptual heat extraction design which will be used for a rough estimate of the size of the ORC. The properties of the geothermal fluid and any constraints on minimum temperature of the geothermal fluid will determine what type of heat exchanger should be selected and the amount of heat available. The operating conditions of the working fluid are given consideration however the geothermal fluid constraints will be the deciding factor. A rough estimate of land use should also be made in case there are space limitations. A rough estimate for the size of an ORC is 1415m2/MW [10]. The final step at the prospecting stage is estimating the proposed ORC performance, such as the power output and efficiency. Initial cost estimates and calculation of the payback period can be made after this step and they will significantly influence the decision on whether or not to progress with the project. At this point in the project the risk of failure is still high because a comprehensive analysis still needs to be done, and therefore the investment in the prospecting stage should be minimal to avoid significant financial loss if the project is abandoned. 2.2 Feasibility The purpose of the feasibility stage is to further develop the initial approximate model from the prospect stage to determine if the project is economically and technically feasible. The feasibility study should also provide the best possible solution for the client. The feasibility stage should only be carried out once it is clear there is a chance of utilizing the geothermal fluid because a comprehensive feasibility study requires resources and time. The final outcome of a comprehensive feasibility study can be used as Figure 5. Flow diagram outlining the feasibility stage of the current version of the ORC standard The selection of the working fluid is the first step in a more comprehensive analysis. The working fluid must be able to operate between the system constraints set by the geothermal fluid and the ambient environment. Other important considerations for the selection of working fluid include the availability of the working fluid, the toxicity, and compatibility with component materials. Typically large geothermal operations use hydrocarbons as the working fluid, such as pentane in the Rotokawa OECs [4] or butane in the planned Pamukuren Atlas Copco ORC [6], because they are relatively cheap and readily available. ORCs that utilize lower temperature geothermal fluids tend to use refrigerants, such as the UTC PureCycle at Chena that uses R134a as the working fluid [11]. The thermal model from the prospecting stage is reviewed and the components of the ORC are modeled in more detail using the parameters for the selected working fluid. The modeling process involved here should also investigate the possibility of a preheater or a regenerator. A regenerator is commonly used when there is a low temperature limit required on the geothermal fluid to avoid scaling. The thermal model will also determine required flow rates of working fluid, geothermal fluid, and cooling fluid for the optimum design. ORC outputs from this analysis also include theoretical parasitic losses on the system and the pressure drop through the heat exchangers. The detailed thermal model can be used to better understand the economics of the system and to determine a proposed initial capital cost. There are some models available such as the GT-Small model [12], which provide approximate estimates of the capital cost of small geothermal projects. An economic analysis of the system can determine the unit 35th New Zealand Geothermal Workshop: 2013 Proceedings 17 – 20 November 2013 Rotorua, New ZealandPDF Image | DEVELOPMENT OF A LOW TEMPERATURE GEOTHERMAL ORGANIC RANKINE

PDF Search Title:

DEVELOPMENT OF A LOW TEMPERATURE GEOTHERMAL ORGANIC RANKINEOriginal File Name Searched:

Taylor_L_Final.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |