PDF Publication Title:

Text from PDF Page: 003

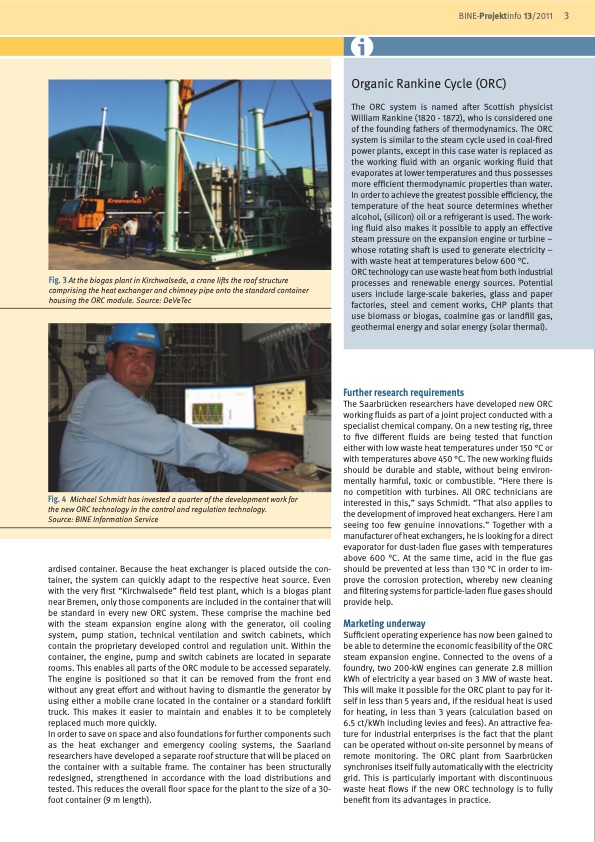

BINE-Projektinfo 13/2011 3 Fig. 3 At the biogas plant in Kirchwalsede, a crane lifts the roof structure comprising the heat exchanger and chimney pipe onto the standard container housing the ORC module. Source: DeVeTec Organic Rankine Cycle (ORC) The ORC system is named after Scottish physicist William Rankine (1820 - 1872), who is considered one of the founding fathers of thermodynamics. The ORC system is similar to the steam cycle used in coal-fired power plants, except in this case water is replaced as the working fluid with an organic working fluid that evaporates at lower temperatures and thus possesses more efficient thermodynamic properties than water. In order to achieve the greatest possible efficiency, the temperature of the heat source determines whether alcohol, (silicon) oil or a refrigerant is used. The work- ing fluid also makes it possible to apply an effective steam pressure on the expansion engine or turbine – whose rotating shaft is used to generate electricity – with waste heat at temperatures below 600 °C. ORC technology can use waste heat from both industrial processes and renewable energy sources. Potential users include large-scale bakeries, glass and paper factories, steel and cement works, CHP plants that use biomass or biogas, coalmine gas or landfill gas, geothermal energy and solar energy (solar thermal). Fig. 4 Michael Schmidt has invested a quarter of the development work for the new ORC technology in the control and regulation technology. Source: BINE Information Service ardised container. Because the heat exchanger is placed outside the con- tainer, the system can quickly adapt to the respective heat source. Even with the very first “Kirchwalsede” field test plant, which is a biogas plant near Bremen, only those components are included in the container that will be standard in every new ORC system. These comprise the machine bed with the steam expansion engine along with the generator, oil cooling system, pump station, technical ventilation and switch cabinets, which contain the proprietary developed control and regulation unit. Within the container, the engine, pump and switch cabinets are located in separate rooms. This enables all parts of the ORC module to be accessed separately. The engine is positioned so that it can be removed from the front end without any great effort and without having to dismantle the generator by using either a mobile crane located in the container or a standard forklift truck. This makes it easier to maintain and enables it to be completely replaced much more quickly. In order to save on space and also foundations for further components such as the heat exchanger and emergency cooling systems, the Saarland researchers have developed a separate roof structure that will be placed on the container with a suitable frame. The container has been structurally redesigned, strengthened in accordance with the load distributions and tested. This reduces the overall floor space for the plant to the size of a 30- foot container (9 m length). Further research requirements The Saarbrücken researchers have developed new ORC working fluids as part of a joint project conducted with a specialist chemical company. On a new testing rig, three to five different fluids are being tested that function either with low waste heat temperatures under 150 °C or with temperatures above 450 °C. The new working fluids should be durable and stable, without being environ- mentally harmful, toxic or combustible. “Here there is no competition with turbines. All ORC technicians are interested in this,” says Schmidt. “That also applies to the development of improved heat exchangers. Here I am seeing too few genuine innovations.” Together with a manufacturer of heat exchangers, he is looking for a direct evaporator for dust-laden flue gases with temperatures above 600 °C. At the same time, acid in the flue gas should be prevented at less than 130 °C in order to im- prove the corrosion protection, whereby new cleaning and filtering systems for particle-laden flue gases should provide help. Marketing underway Sufficient operating experience has now been gained to be able to determine the economic feasibility of the ORC steam expansion engine. Connected to the ovens of a foundry, two 200-kW engines can generate 2.8 million kWh of electricity a year based on 3 MW of waste heat. This will make it possible for the ORC plant to pay for it- self in less than 5 years and, if the residual heat is used for heating, in less than 3 years (calculation based on 6.5 ct/kWh including levies and fees). An attractive fea- ture for industrial enterprises is the fact that the plant can be operated without on-site personnel by means of remote monitoring. The ORC plant from Saarbrücken synchronises itself fully automatically with the electricity grid. This is particularly important with discontinuous waste heat flows if the new ORC technology is to fully benefit from its advantages in practice.PDF Image | Transforming waste heat into electricity

PDF Search Title:

Transforming waste heat into electricityOriginal File Name Searched:

ProjektInfo_1311_engl_internetx.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |