PDF Publication Title:

Text from PDF Page: 002

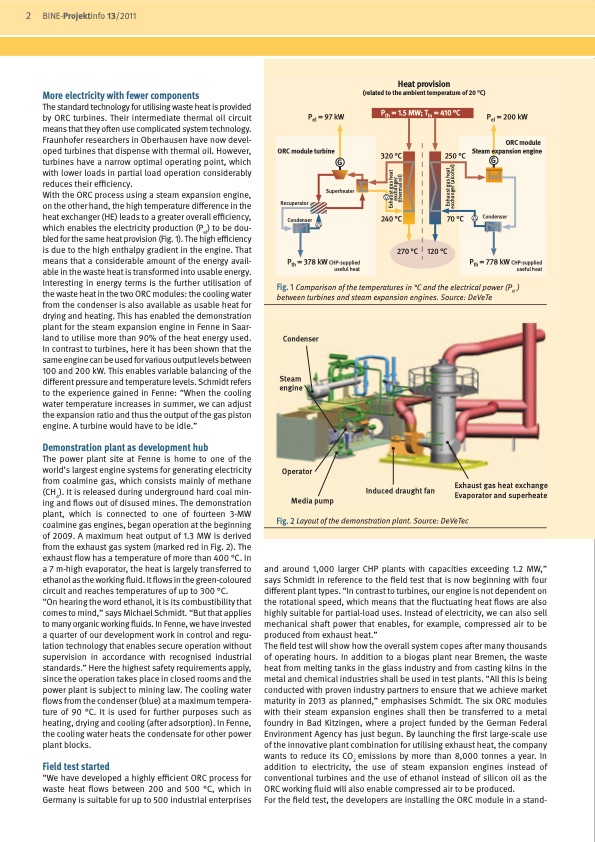

2 BINE-Projektinfo 13/2011 More electricity with fewer components The standard technology for utilising waste heat is provided by ORC turbines. Their intermediate thermal oil circuit means that they often use complicated system technology. Fraunhofer researchers in Oberhausen have now devel- oped turbines that dispense with thermal oil. However, turbines have a narrow optimal operating point, which with lower loads in partial load operation considerably reduces their efficiency. With the ORC process using a steam expansion engine, on the other hand, the high temperature difference in the heat exchanger (HE) leads to a greater overall efficiency, which enables the electricity production (Pel) to be dou- bled for the same heat provision (Fig. 1). The high efficiency is due to the high enthalpy gradient in the engine. That means that a considerable amount of the energy avail- able in the waste heat is transformed into usable energy. Interesting in energy terms is the further utilisation of the waste heat in the two ORC modules: the cooling water from the condenser is also available as usable heat for drying and heating. This has enabled the demonstration plant for the steam expansion engine in Fenne in Saar- land to utilise more than 90% of the heat energy used. In contrast to turbines, here it has been shown that the same engine can be used for various output levels between 100 and 200 kW. This enables variable balancing of the different pressure and temperature levels. Schmidt refers to the experience gained in Fenne: “When the cooling water temperature increases in summer, we can adjust the expansion ratio and thus the output of the gas piston engine. A turbine would have to be idle.” Demonstration plant as development hub The power plant site at Fenne is home to one of the world’s largest engine systems for generating electricity from coalmine gas, which consists mainly of methane (CH4). It is released during underground hard coal min- ing and flows out of disused mines. The demonstration plant, which is connected to one of fourteen 3-MW coalmine gas engines, began operation at the beginning of 2009. A maximum heat output of 1.3 MW is derived from the exhaust gas system (marked red in Fig. 2). The exhaust flow has a temperature of more than 400 °C. In a 7 m-high evaporator, the heat is largely transferred to ethanol as the working fluid. It flows in the green-coloured circuit and reaches temperatures of up to 300 °C. “On hearing the word ethanol, it is its combustibility that comes to mind,” says Michael Schmidt. “But that applies to many organic working fluids. In Fenne, we have invested a quarter of our development work in control and regu- lation technology that enables secure operation without supervision in accordance with recognised industrial standards.” Here the highest safety requirements apply, since the operation takes place in closed rooms and the power plant is subject to mining law. The cooling water flows from the condenser (blue) at a maximum tempera- ture of 90 °C. It is used for further purposes such as heating, drying and cooling (after adsorption). In Fenne, the cooling water heats the condensate for other power plant blocks. Field test started “We have developed a highly efficient ORC process for waste heat flows between 200 and 500 °C, which in Germany is suitable for up to 500 industrial enterprises Heat provision (related to the ambient temperature of 20 °C) =97kW ORC module turbine Pth =1.5MW;Tin =410°C 320 °C 250 °C P =200kW el ORC module Steam expansion engine P el GG Superheater Recuperator Condenser 240 °C 270 °C 70 °C 120 °C Condenser Pth = 778 kW CHP-supplied useful heat Pth = 378 kW CHP-supplied useful heat Fig. 1 Comparison of the temperatures in °C and the electrical power (Pel ) between turbines and steam expansion engines. Source: DeVeTe Condenser Steam engine Operator Media pump Induced draught fan Exhaust gas heat exchanger Evaporator and superheater Fig. 2 Layout of the demonstration plant. Source: DeVeTec and around 1,000 larger CHP plants with capacities exceeding 1.2 MW,” says Schmidt in reference to the field test that is now beginning with four different plant types. “In contrast to turbines, our engine is not dependent on the rotational speed, which means that the fluctuating heat flows are also highly suitable for partial-load uses. Instead of electricity, we can also sell mechanical shaft power that enables, for example, compressed air to be produced from exhaust heat.” The field test will show how the overall system copes after many thousands of operating hours. In addition to a biogas plant near Bremen, the waste heat from melting tanks in the glass industry and from casting kilns in the metal and chemical industries shall be used in test plants. “All this is being conducted with proven industry partners to ensure that we achieve market maturity in 2013 as planned,” emphasises Schmidt. The six ORC modules with their steam expansion engines shall then be transferred to a metal foundry in Bad Kitzingen, where a project funded by the German Federal Environment Agency has just begun. By launching the first large-scale use of the innovative plant combination for utilising exhaust heat, the company wants to reduce its CO2 emissions by more than 8,000 tonnes a year. In addition to electricity, the use of steam expansion engines instead of conventional turbines and the use of ethanol instead of silicon oil as the ORC working fluid will also enable compressed air to be produced. For the field test, the developers are installing the ORC module in a stand- Exhaust gas heat exchanger (thermal oil) Exhaust gas heat exchanger (alcohol)PDF Image | Transforming waste heat into electricity

PDF Search Title:

Transforming waste heat into electricityOriginal File Name Searched:

ProjektInfo_1311_engl_internetx.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |