PDF Publication Title:

Text from PDF Page: 004

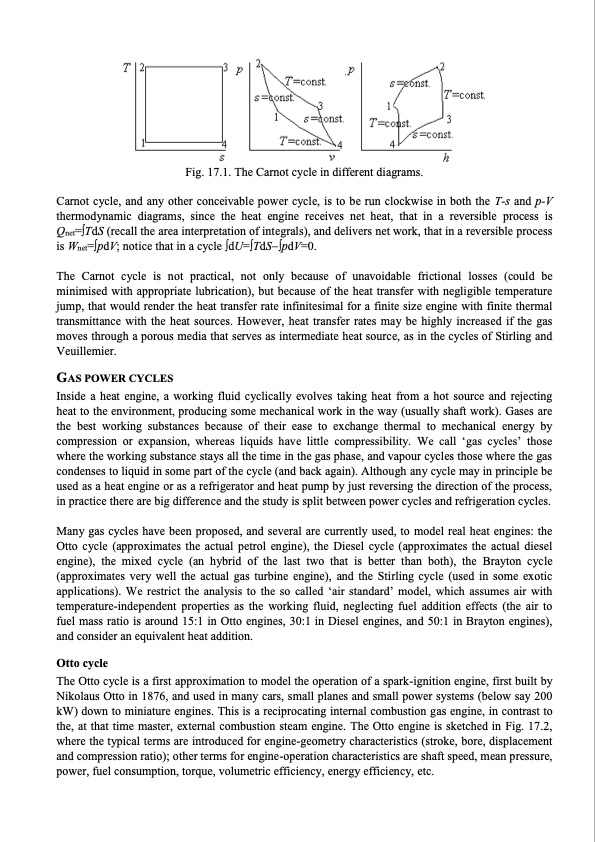

Fig. 17.1. The Carnot cycle in different diagrams. Carnot cycle, and any other conceivable power cycle, is to be run clockwise in both the T-s and p-V thermodynamic diagrams, since the heat engine receives net heat, that in a reversible process is Qnet=TdS (recall the area interpretation of integrals), and delivers net work, that in a reversible process is Wnet=pdV; notice that in a cycle dU=TdSpdV=0. The Carnot cycle is not practical, not only because of unavoidable frictional losses (could be minimised with appropriate lubrication), but because of the heat transfer with negligible temperature jump, that would render the heat transfer rate infinitesimal for a finite size engine with finite thermal transmittance with the heat sources. However, heat transfer rates may be highly increased if the gas moves through a porous media that serves as intermediate heat source, as in the cycles of Stirling and Veuillemier. GAS POWER CYCLES Inside a heat engine, a working fluid cyclically evolves taking heat from a hot source and rejecting heat to the environment, producing some mechanical work in the way (usually shaft work). Gases are the best working substances because of their ease to exchange thermal to mechanical energy by compression or expansion, whereas liquids have little compressibility. We call ‘gas cycles’ those where the working substance stays all the time in the gas phase, and vapour cycles those where the gas condenses to liquid in some part of the cycle (and back again). Although any cycle may in principle be used as a heat engine or as a refrigerator and heat pump by just reversing the direction of the process, in practice there are big difference and the study is split between power cycles and refrigeration cycles. Many gas cycles have been proposed, and several are currently used, to model real heat engines: the Otto cycle (approximates the actual petrol engine), the Diesel cycle (approximates the actual diesel engine), the mixed cycle (an hybrid of the last two that is better than both), the Brayton cycle (approximates very well the actual gas turbine engine), and the Stirling cycle (used in some exotic applications). We restrict the analysis to the so called ‘air standard’ model, which assumes air with temperature-independent properties as the working fluid, neglecting fuel addition effects (the air to fuel mass ratio is around 15:1 in Otto engines, 30:1 in Diesel engines, and 50:1 in Brayton engines), and consider an equivalent heat addition. Otto cycle The Otto cycle is a first approximation to model the operation of a spark-ignition engine, first built by Nikolaus Otto in 1876, and used in many cars, small planes and small power systems (below say 200 kW) down to miniature engines. This is a reciprocating internal combustion gas engine, in contrast to the, at that time master, external combustion steam engine. The Otto engine is sketched in Fig. 17.2, where the typical terms are introduced for engine-geometry characteristics (stroke, bore, displacement and compression ratio); other terms for engine-operation characteristics are shaft speed, mean pressure, power, fuel consumption, torque, volumetric efficiency, energy efficiency, etc.PDF Image | THERMAL MACHINES AND HEAT ENGINES

PDF Search Title:

THERMAL MACHINES AND HEAT ENGINESOriginal File Name Searched:

Power.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |