PDF Publication Title:

Text from PDF Page: 003

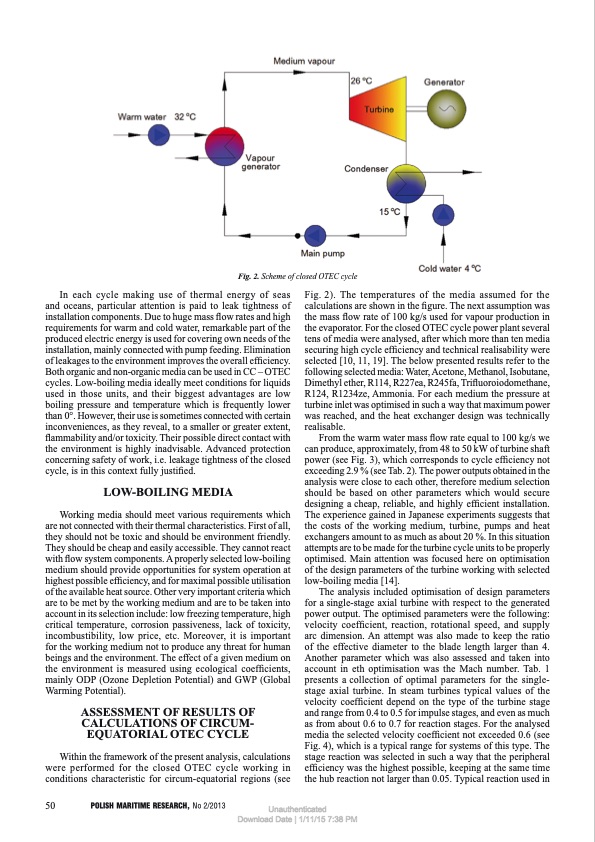

In each cycle making use of thermal energy of seas and oceans, particular attention is paid to leak tightness of installation components. Due to huge mass flow rates and high requirements for warm and cold water, remarkable part of the produced electric energy is used for covering own needs of the installation, mainly connected with pump feeding. Elimination of leakages to the environment improves the overall efficiency. Both organic and non-organic media can be used in CC – OTEC cycles. Low-boiling media ideally meet conditions for liquids used in those units, and their biggest advantages are low boiling pressure and temperature which is frequently lower than 0°. However, their use is sometimes connected with certain inconveniences, as they reveal, to a smaller or greater extent, flammability and/or toxicity. Their possible direct contact with the environment is highly inadvisable. Advanced protection concerning safety of work, i.e. leakage tightness of the closed cycle, is in this context fully justified. LOW-BOILING MEDIA Working media should meet various requirements which are not connected with their thermal characteristics. First of all, they should not be toxic and should be environment friendly. They should be cheap and easily accessible. They cannot react with flow system components. A properly selected low-boiling medium should provide opportunities for system operation at highest possible efficiency, and for maximal possible utilisation of the available heat source. Other very important criteria which are to be met by the working medium and are to be taken into account in its selection include: low freezing temperature, high critical temperature, corrosion passiveness, lack of toxicity, incombustibility, low price, etc. Moreover, it is important for the working medium not to produce any threat for human beings and the environment. The effect of a given medium on the environment is measured using ecological coefficients, mainly ODP (Ozone Depletion Potential) and GWP (Global Warming Potential). ASSESSMENT OF RESULTS OF CALCULATIONS OF CIRCUM- EQUATORIAL OTEC CYCLE Within the framework of the present analysis, calculations were performed for the closed OTEC cycle working in conditions characteristic for circum-equatorial regions (see Fig. 2). The temperatures of the media assumed for the calculations are shown in the figure. The next assumption was the mass flow rate of 100 kg/s used for vapour production in the evaporator. For the closed OTEC cycle power plant several tens of media were analysed, after which more than ten media securing high cycle efficiency and technical realisability were selected [10, 11, 19]. The below presented results refer to the following selected media: Water, Acetone, Methanol, Isobutane, Dimethyl ether, R114, R227ea, R245fa, Trifluoroiodomethane, R124, R1234ze, Ammonia. For each medium the pressure at turbine inlet was optimised in such a way that maximum power was reached, and the heat exchanger design was technically realisable. From the warm water mass flow rate equal to 100 kg/s we can produce, approximately, from 48 to 50 kW of turbine shaft power (see Fig. 3), which corresponds to cycle efficiency not exceeding 2.9 % (see Tab. 2). The power outputs obtained in the analysis were close to each other, therefore medium selection should be based on other parameters which would secure designing a cheap, reliable, and highly efficient installation. The experience gained in Japanese experiments suggests that the costs of the working medium, turbine, pumps and heat exchangers amount to as much as about 20 %. In this situation attempts are to be made for the turbine cycle units to be properly optimised. Main attention was focused here on optimisation of the design parameters of the turbine working with selected low-boiling media [14]. The analysis included optimisation of design parameters for a single-stage axial turbine with respect to the generated power output. The optimised parameters were the following: velocity coefficient, reaction, rotational speed, and supply arc dimension. An attempt was also made to keep the ratio of the effective diameter to the blade length larger than 4. Another parameter which was also assessed and taken into account in eth optimisation was the Mach number. Tab. 1 presents a collection of optimal parameters for the single- stage axial turbine. In steam turbines typical values of the velocity coefficient depend on the type of the turbine stage and range from 0.4 to 0.5 for impulse stages, and even as much as from about 0.6 to 0.7 for reaction stages. For the analysed media the selected velocity coefficient not exceeded 0.6 (see Fig. 4), which is a typical range for systems of this type. The stage reaction was selected in such a way that the peripheral efficiency was the highest possible, keeping at the same time the hub reaction not larger than 0.05. Typical reaction used in 50 POLISH MARITIME RESEARCH, No 2/2013 Unauthenticated Download Date | 1/11/15 7:38 PM Fig. 2. Scheme of closed OTEC cyclePDF Image | Design analysis of ORC micro-turbines making use of thermal energy

PDF Search Title:

Design analysis of ORC micro-turbines making use of thermal energyOriginal File Name Searched:

pomr_2013_0016.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |