PDF Publication Title:

Text from PDF Page: 006

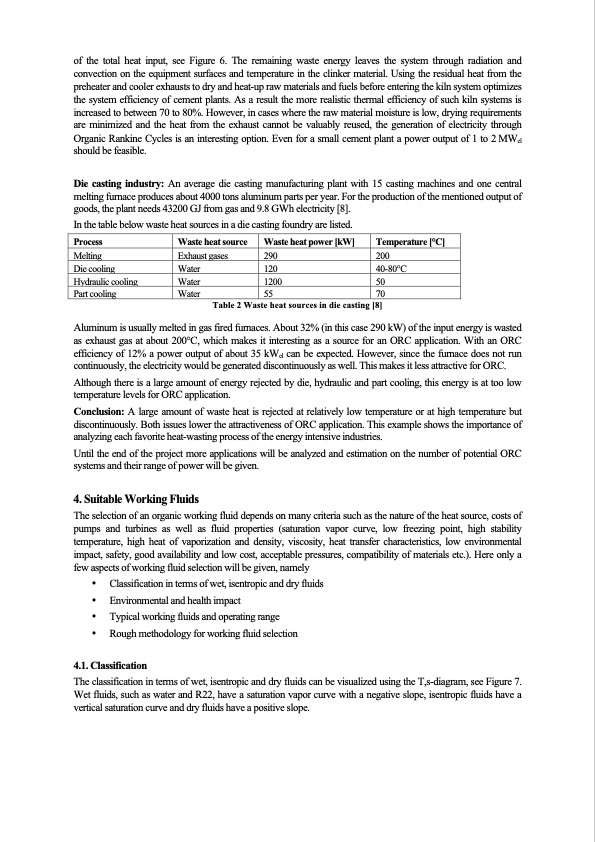

of the total heat input, see Figure 6. The remaining waste energy leaves the system through radiation and convection on the equipment surfaces and temperature in the clinker material. Using the residual heat from the preheater and cooler exhausts to dry and heat-up raw materials and fuels before entering the kiln system optimizes the system efficiency of cement plants. As a result the more realistic thermal efficiency of such kiln systems is increased to between 70 to 80%. However, in cases where the raw material moisture is low, drying requirements are minimized and the heat from the exhaust cannot be valuably reused, the generation of electricity through Organic Rankine Cycles is an interesting option. Even for a small cement plant a power output of 1 to 2 MWel should be feasible. Die casting industry: An average die casting manufacturing plant with 15 casting machines and one central melting furnace produces about 4000 tons aluminum parts per year. For the production of the mentioned output of goods, the plant needs 43200 GJ from gas and 9.8 GWh electricity [8]. In the table below waste heat sources in a die casting foundry are listed. Process Melting Die cooling Hydraulic cooling Part cooling Waste heat source Exhaust gases Water Water Water Waste heat power [kW] 290 120 1200 55 Temperature [°C] 200 40-80°C 50 70 Table 2 Waste heat sources in die casting [8] Aluminum is usually melted in gas fired furnaces. About 32% (in this case 290 kW) of the input energy is wasted as exhaust gas at about 200°C, which makes it interesting as a source for an ORC application. With an ORC efficiency of 12% a power output of about 35 kWel can be expected. However, since the furnace does not run continuously, the electricity would be generated discontinuously as well. This makes it less attractive for ORC. Although there is a large amount of energy rejected by die, hydraulic and part cooling, this energy is at too low temperature levels for ORC application. Conclusion: A large amount of waste heat is rejected at relatively low temperature or at high temperature but discontinuously. Both issues lower the attractiveness of ORC application. This example shows the importance of analyzing each favorite heat-wasting process of the energy intensive industries. Until the end of the project more applications will be analyzed and estimation on the number of potential ORC systems and their range of power will be given. 4. Suitable Working Fluids The selection of an organic working fluid depends on many criteria such as the nature of the heat source, costs of pumps and turbines as well as fluid properties (saturation vapor curve, low freezing point, high stability temperature, high heat of vaporization and density, viscosity, heat transfer characteristics, low environmental impact, safety, good availability and low cost, acceptable pressures, compatibility of materials etc.). Here only a few aspects of working fluid selection will be given, namely • Classification in terms of wet, isentropic and dry fluids • Environmental and health impact • Typical working fluids and operating range • Rough methodology for working fluid selection 4.1. Classification The classification in terms of wet, isentropic and dry fluids can be visualized using the T,s-diagram, see Figure 7. Wet fluids, such as water and R22, have a saturation vapor curve with a negative slope, isentropic fluids have a vertical saturation curve and dry fluids have a positive slope.PDF Image | Application of Organic Rankine Cycles (ORC)

PDF Search Title:

Application of Organic Rankine Cycles (ORC)Original File Name Searched:

ORC_Final_Paper_WEC2011_2011_07_30.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |