PDF Publication Title:

Text from PDF Page: 002

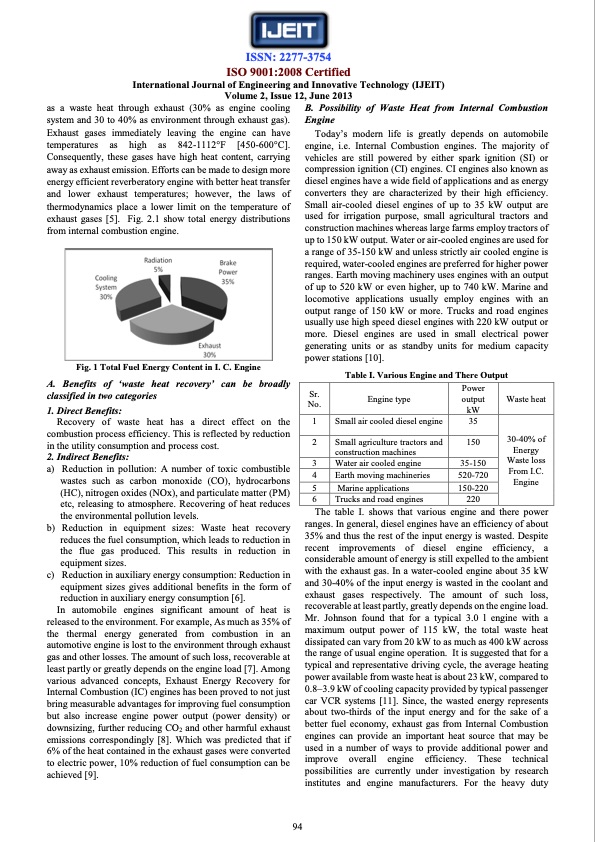

ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 12, June 2013 as a waste heat through exhaust (30% as engine cooling system and 30 to 40% as environment through exhaust gas). Exhaust gases immediately leaving the engine can have temperatures as high as 842-1112°F [450-600°C]. Consequently, these gases have high heat content, carrying away as exhaust emission. Efforts can be made to design more energy efficient reverberatory engine with better heat transfer and lower exhaust temperatures; however, the laws of thermodynamics place a lower limit on the temperature of exhaust gases [5]. Fig. 2.1 show total energy distributions from internal combustion engine. Fig. 1 Total Fuel Energy Content in I. C. Engine A. Benefits of ‘waste heat recovery’ can be broadly classified in two categories 1. Direct Benefits: Recovery of waste heat has a direct effect on the combustion process efficiency. This is reflected by reduction in the utility consumption and process cost. 2. Indirect Benefits: B. Possibility of Waste Heat from Internal Combustion Engine Today‟s modern life is greatly depends on automobile engine, i.e. Internal Combustion engines. The majority of vehicles are still powered by either spark ignition (SI) or compression ignition (CI) engines. CI engines also known as diesel engines have a wide field of applications and as energy converters they are characterized by their high efficiency. Small air-cooled diesel engines of up to 35 kW output are used for irrigation purpose, small agricultural tractors and construction machines whereas large farms employ tractors of up to 150 kW output. Water or air-cooled engines are used for a range of 35-150 kW and unless strictly air cooled engine is required, water-cooled engines are preferred for higher power ranges. Earth moving machinery uses engines with an output of up to 520 kW or even higher, up to 740 kW. Marine and locomotive applications usually employ engines with an output range of 150 kW or more. Trucks and road engines usually use high speed diesel engines with 220 kW output or more. Diesel engines are used in small electrical power generating units or as standby units for medium capacity power stations [10]. Table I. Various Engine and There Output a) b) c) Reduction in pollution: A number of toxic combustible wastes such as carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and particulate matter (PM) etc, releasing to atmosphere. Recovering of heat reduces the environmental pollution levels. Reduction in equipment sizes: Waste heat recovery reduces the fuel consumption, which leads to reduction in the flue gas produced. This results in reduction in equipment sizes. Reduction in auxiliary energy consumption: Reduction in equipment sizes gives additional benefits in the form of reduction in auxiliary energy consumption [6]. Sr. No. 1 2 3 4 5 6 Engine type Small air cooled diesel engine Small agriculture tractors and construction machines Water air cooled engine Earth moving machineries Marine applications Trucks and road engines Power output kW 35 150 35-150 520-720 150-220 220 Waste heat 30-40% of Energy Waste loss From I.C. Engine In automobile engines significant amount of heat is released to the environment. For example, As much as 35% of the thermal energy generated from combustion in an automotive engine is lost to the environment through exhaust gas and other losses. The amount of such loss, recoverable at least partly or greatly depends on the engine load [7]. Among various advanced concepts, Exhaust Energy Recovery for Internal Combustion (IC) engines has been proved to not just bring measurable advantages for improving fuel consumption but also increase engine power output (power density) or downsizing, further reducing CO2 and other harmful exhaust emissions correspondingly [8]. Which was predicted that if 6% of the heat contained in the exhaust gases were converted to electric power, 10% reduction of fuel consumption can be achieved [9]. 94 The ranges. In general, diesel engines have an efficiency of about 35% and thus the rest of the input energy is wasted. Despite recent improvements of diesel engine efficiency, a considerable amount of energy is still expelled to the ambient with the exhaust gas. In a water-cooled engine about 35 kW and 30-40% of the input energy is wasted in the coolant and exhaust gases respectively. The amount of such loss, recoverable at least partly, greatly depends on the engine load. Mr. Johnson found that for a typical 3.0 l engine with a maximum output power of 115 kW, the total waste heat dissipated can vary from 20 kW to as much as 400 kW across the range of usual engine operation. It is suggested that for a typical and representative driving cycle, the average heating power available from waste heat is about 23 kW, compared to 0.8–3.9 kW of cooling capacity provided by typical passenger car VCR systems [11]. Since, the wasted energy represents about two-thirds of the input energy and for the sake of a better fuel economy, exhaust gas from Internal Combustion engines can provide an important heat source that may be used in a number of ways to provide additional power and improve overall engine efficiency. These technical possibilities are currently under investigation by research institutes and engine manufacturers. For the heavy duty table I. shows that various engine and there powerPDF Image | Review on Exhaust Gas Heat Recovery for I.C. Engine

PDF Search Title:

Review on Exhaust Gas Heat Recovery for I.C. EngineOriginal File Name Searched:

IJEIT1412201306_18.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |