PDF Publication Title:

Text from PDF Page: 004

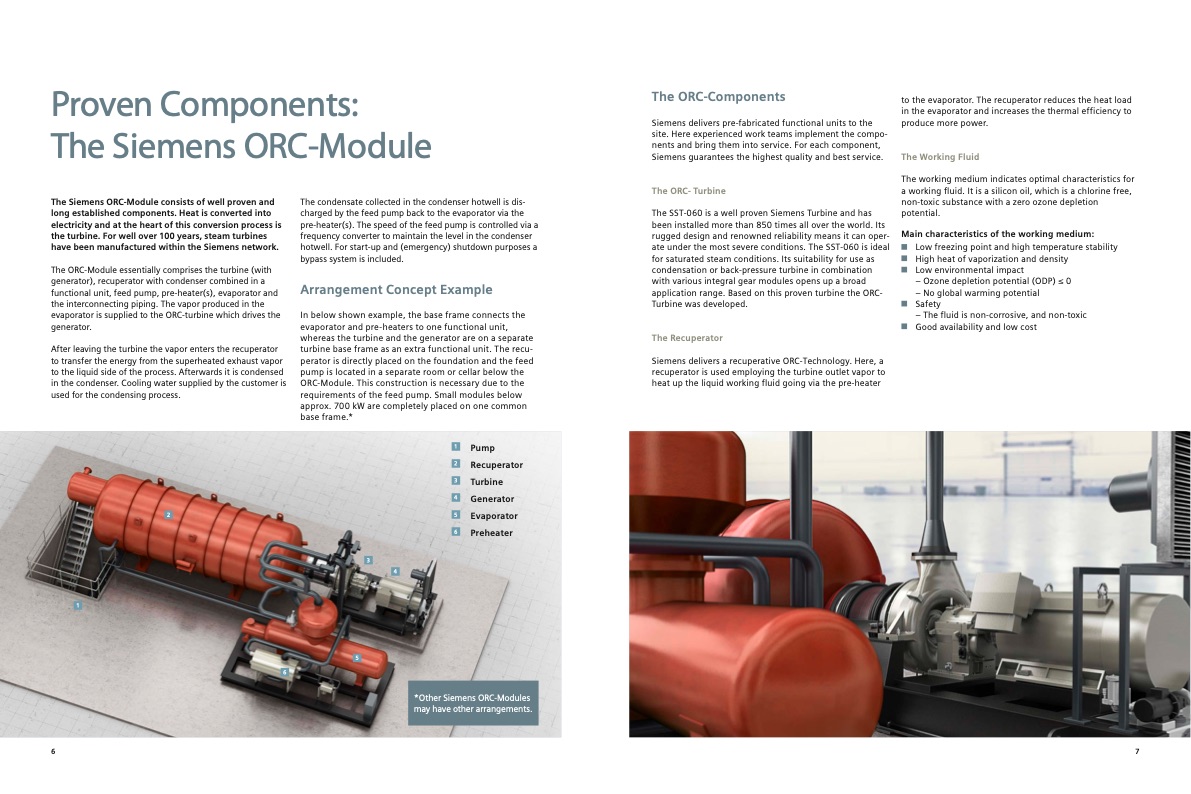

1 3 4 5 1 2 3 4 25 6 Pump Recuperator Turbine Generator Evaporator Preheater 6 *Other Siemens ORC-Modules may have other arrangements. Proven Components: The Siemens ORC-Module The ORC-Components Siemens delivers pre-fabricated functional units to the site. Here experienced work teams implement the compo- nents and bring them into service. For each component, Siemens guarantees the highest quality and best service. The ORC- Turbine The SST-060 is a well proven Siemens Turbine and has been installed more than 850 times all over the world. Its rugged design and renowned reliability means it can oper- ate under the most severe conditions. The SST-060 is ideal for saturated steam conditions. Its suitability for use as condensation or back-pressure turbine in combination with various integral gear modules opens up a broad application range. Based on this proven turbine the ORC- Turbine was developed. The Recuperator Siemens delivers a recuperative ORC-Technology. Here, a recuperator is used employing the turbine outlet vapor to heat up the liquid working fluid going via the pre-heater to the evaporator. The recuperator reduces the heat load in the evaporator and increases the thermal efficiency to produce more power. The Working Fluid The working medium indicates optimal characteristics for a working fluid. It is a silicon oil, which is a chlorine free, non-toxic substance with a zero ozone depletion potential. Main characteristics of the working medium: Low freezing point and high temperature stability High heat of vaporization and density Low environmental impact – Ozone depletion potential (ODP) ≤ 0 – No global warming potential Safety – The fluid is non-corrosive, and non-toxic Good availability and low cost The Siemens ORC-Module consists of well proven and long established components. Heat is converted into electricity and at the heart of this conversion process is the turbine. For well over 100 years, steam turbines have been manufactured within the Siemens network. The ORC-Module essentially comprises the turbine (with generator), recuperator with condenser combined in a functional unit, feed pump, pre-heater(s), evaporator and the interconnecting piping. The vapor produced in the evaporator is supplied to the ORC-turbine which drives the generator. After leaving the turbine the vapor enters the recuperator to transfer the energy from the superheated exhaust vapor to the liquid side of the process. Afterwards it is condensed in the condenser. Cooling water supplied by the customer is used for the condensing process. The condensate collected in the condenser hotwell is dis- charged by the feed pump back to the evaporator via the pre-heater(s). The speed of the feed pump is controlled via a frequency converter to maintain the level in the condenser hotwell. For start-up and (emergency) shutdown purposes a bypass system is included. Arrangement Concept Example In below shown example, the base frame connects the evaporator and pre-heaters to one functional unit, whereas the turbine and the generator are on a separate turbine base frame as an extra functional unit. The recu- perator is directly placed on the foundation and the feed pump is located in a separate room or cellar below the ORC-Module. This construction is necessary due to the requirements of the feed pump. Small modules below approx. 700 kW are completely placed on one common base frame.* 67PDF Image | Waste Heat Recovery with ORC

PDF Search Title:

Waste Heat Recovery with ORCOriginal File Name Searched:

brochure_siemens_orc_module_e.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |