PDF Publication Title:

Text from PDF Page: 009

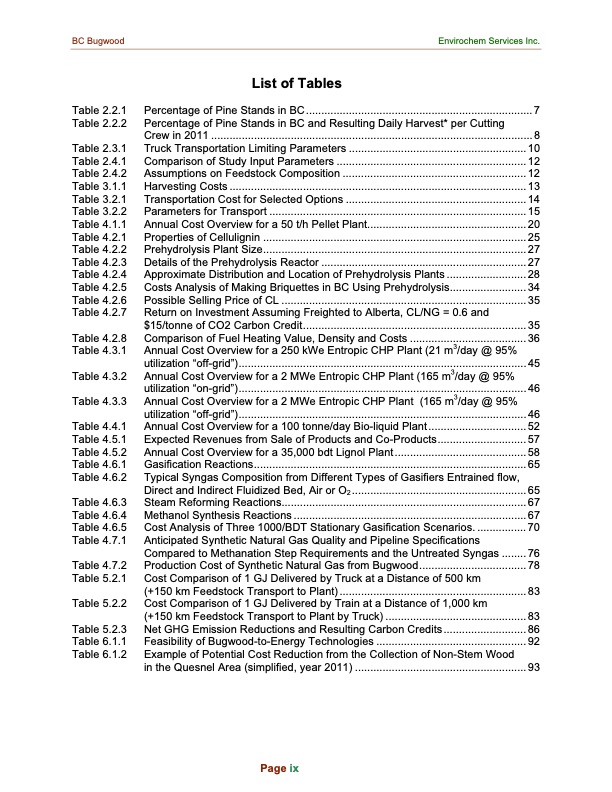

BC Bugwood Envirochem Services Inc. Table 2.2.1 Table 2.2.2 Table 2.3.1 Table 2.4.1 Table 2.4.2 Table 3.1.1 Table 3.2.1 Table 3.2.2 Table 4.1.1 Table 4.2.1 Table 4.2.2 Table 4.2.3 Table 4.2.4 Table 4.2.5 Table 4.2.6 Table 4.2.7 Table 4.2.8 Table 4.3.1 Table 4.3.2 Table 4.3.3 Table 4.4.1 Table 4.5.1 Table 4.5.2 Table 4.6.1 Table 4.6.2 Table 4.6.3 Table 4.6.4 Table 4.6.5 Table 4.7.1 Table 4.7.2 Table 5.2.1 Table 5.2.2 Table 5.2.3 Table 6.1.1 Table 6.1.2 List of Tables Percentage of Pine Stands in BC .......................................................................... 7 Percentage of Pine Stands in BC and Resulting Daily Harvest* per Cutting Crew in 2011 ......................................................................................................... 8 Truck Transportation Limiting Parameters .......................................................... 10 Comparison of Study Input Parameters .............................................................. 12 Assumptions on Feedstock Composition ............................................................ 12 Harvesting Costs ................................................................................................. 13 Transportation Cost for Selected Options ........................................................... 14 Parameters for Transport .................................................................................... 15 Annual Cost Overview for a 50 t/h Pellet Plant.................................................... 20 Properties of Cellulignin ...................................................................................... 25 Prehydrolysis Plant Size...................................................................................... 27 Details of the Prehydrolysis Reactor ................................................................... 27 Approximate Distribution and Location of Prehydrolysis Plants .......................... 28 Costs Analysis of Making Briquettes in BC Using Prehydrolysis......................... 34 Possible Selling Price of CL ................................................................................ 35 Return on Investment Assuming Freighted to Alberta, CL/NG = 0.6 and $15/tonne of CO2 Carbon Credit......................................................................... 35 Comparison of Fuel Heating Value, Density and Costs ...................................... 36 Annual Cost Overview for a 250 kWe Entropic CHP Plant (21 m3/day @ 95% utilization “off-grid”).............................................................................................. 45 Annual Cost Overview for a 2 MWe Entropic CHP Plant (165 m3/day @ 95% utilization “on-grid”).............................................................................................. 46 Annual Cost Overview for a 2 MWe Entropic CHP Plant (165 m3/day @ 95% utilization “off-grid”).............................................................................................. 46 Annual Cost Overview for a 100 tonne/day Bio-liquid Plant ................................ 52 Expected Revenues from Sale of Products and Co-Products ............................. 57 Annual Cost Overview for a 35,000 bdt Lignol Plant ........................................... 58 Gasification Reactions......................................................................................... 65 Typical Syngas Composition from Different Types of Gasifiers Entrained flow, Direct and Indirect Fluidized Bed, Air or O2 ......................................................... 65 Steam Reforming Reactions................................................................................ 67 Methanol Synthesis Reactions ............................................................................ 67 Cost Analysis of Three 1000/BDT Stationary Gasification Scenarios. ................ 70 Anticipated Synthetic Natural Gas Quality and Pipeline Specifications Compared to Methanation Step Requirements and the Untreated Syngas ........ 76 Production Cost of Synthetic Natural Gas from Bugwood ................................... 78 Cost Comparison of 1 GJ Delivered by Truck at a Distance of 500 km (+150 km Feedstock Transport to Plant) ............................................................. 83 Cost Comparison of 1 GJ Delivered by Train at a Distance of 1,000 km (+150 km Feedstock Transport to Plant by Truck) .............................................. 83 Net GHG Emission Reductions and Resulting Carbon Credits ........................... 86 Feasibility of Bugwood-to-Energy Technologies ................................................. 92 Example of Potential Cost Reduction from the Collection of Non-Stem Wood in the Quesnel Area (simplified, year 2011) ........................................................ 93 Page ixPDF Image | IDENTIFYING ENVIRONMENTALLY PREFERABLE USES FOR BIOMASS

PDF Search Title:

IDENTIFYING ENVIRONMENTALLY PREFERABLE USES FOR BIOMASSOriginal File Name Searched:

bib97175.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |