PDF Publication Title:

Text from PDF Page: 005

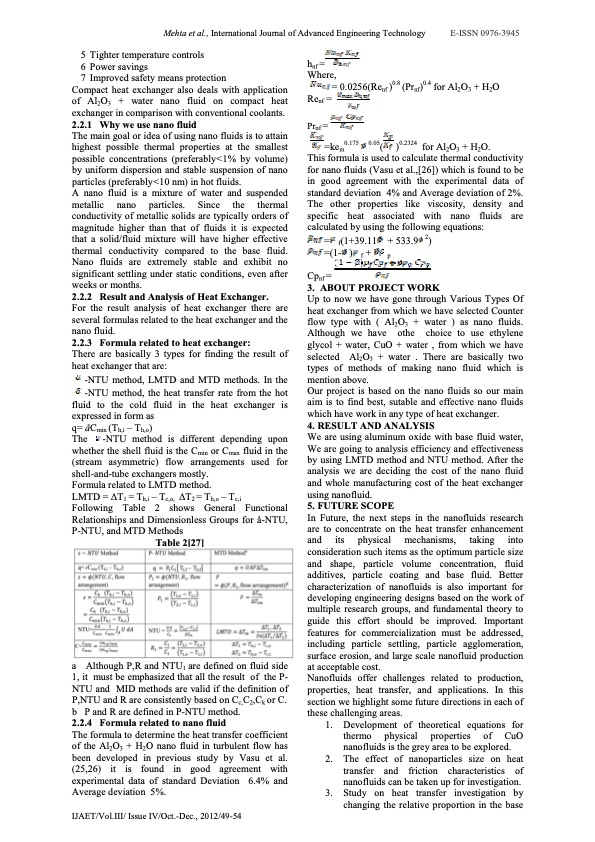

Mehta et al., International Journal of Advanced Engineering Technology E-ISSN 0976-3945 5 Tighter temperature controls 6 Power savings 7 Improved safety means protection Compact heat exchanger also deals with application of Al2O3 + water nano fluid on compact heat exchanger in comparison with conventional coolants. 2.2.1 Why we use nano fluid The main goal or idea of using nano fluids is to attain highest possible thermal properties at the smallest possible concentrations (preferably<1% by volume) by uniform dispersion and stable suspension of nano particles (preferably<10 nm) in hot fluids. A nano fluid is a mixture of water and suspended metallic nano particles. Since the thermal conductivity of metallic solids are typically orders of magnitude higher than that of fluids it is expected that a solid/fluid mixture will have higher effective thermal conductivity compared to the base fluid. Nano fluids are extremely stable and exhibit no significant settling under static conditions, even after weeks or months. 2.2.2 Result and Analysis of Heat Exchanger. For the result analysis of heat exchanger there are several formulas related to the heat exchanger and the nano fluid. 2.2.3 Formula related to heat exchanger: There are basically 3 types for finding the result of heat exchanger that are: -NTU method, LMTD and MTD methods. In the -NTU method, the heat transfer rate from the hot fluid to the cold fluid in the heat exchanger is expressed in form as q= åCmin (Th,i – Th,o) The -NTU method is different depending upon whether the shell fluid is the Cmin or Cmax fluid in the (stream asymmetric) flow arrangements used for shell-and-tube exchangers mostly. Formula related to LMTD method. LMTD=∆T1=Th,i –Tc,o, ∆T2=Th,o –Tc,i Following Table 2 shows General Functional Relationships and Dimensionless Groups for å-NTU, P-NTU, and MTD Methods Table 2[27] a Although P,R and NTU1 are defined on fluid side 1, it must be emphasized that all the result of the P- NTU and MID methods are valid if the definition of P,NTU and R are consistently based on Cc,C2,Ck or C. b P and R are defined in P-NTU method. 2.2.4 Formula related to nano fluid The formula to determine the heat transfer coefficient of the Al2O3 + H2O nano fluid in turbulent flow has been developed in previous study by Vasu et al. (25,26) it is found in good agreement with experimental data of standard Deviation 6.4% and Average deviation 5%. hnf = Where, = 0.0256(Renf )0.8 (Prnf)0.4 for Al2O3 + H2O Renf = Prnf = calculated by using the following equations: = f(1+39.11 + 533.9 2) =(1-)f+ p Cpnf = 3. ABOUT PROJECT WORK Up to now we have gone through Various Types Of heat exchanger from which we have selected Counter flow type with ( Al2O3 + water ) as nano fluids. Although we have othe choice to use ethylene glycol + water, CuO + water , from which we have selected Al2O3 + water . There are basically two types of methods of making nano fluid which is mention above. Our project is based on the nano fluids so our main aim is to find best, sutable and effective nano fluids which have work in any type of heat exchanger. 4. RESULT AND ANALYSIS We are using aluminum oxide with base fluid water, We are going to analysis efficiency and effectiveness by using LMTD method and NTU method. After the analysis we are deciding the cost of the nano fluid and whole manufacturing cost of the heat exchanger using nanofluid. 5. FUTURE SCOPE In Future, the next steps in the nanofluids research are to concentrate on the heat transfer enhancement and its physical mechanisms, taking into consideration such items as the optimum particle size and shape, particle volume concentration, fluid additives, particle coating and base fluid. Better characterization of nanofluids is also important for developing engineering designs based on the work of multiple research groups, and fundamental theory to guide this effort should be improved. Important features for commercialization must be addressed, including particle settling, particle agglomeration, surface erosion, and large scale nanofluid production at acceptable cost. Nanofluids offer challenges related to production, properties, heat transfer, and applications. In this section we highlight some future directions in each of these challenging areas. 1. Development of theoretical equations for thermo physical properties of CuO nanofluids is the grey area to be explored. 2. The effect of nanoparticles size on heat transfer and friction characteristics of nanofluids can be taken up for investigation. 3. Study on heat transfer investigation by changing the relative proportion in the base )0.2324 for Al O + H O. This formula is used to calculate thermal conductivity for nano fluids (Vasu et al.,[26]) which is found to be in good agreement with the experimental data of standard deviation 4% and Average deviation of 2%. The other properties like viscosity, density and specific heat associated with nano fluids are =ke 0.175 0.05( m232 IJAET/Vol.III/ Issue IV/Oct.-Dec., 2012/49-54PDF Image | HEAT EXCHANGER USING NANO FLUID

PDF Search Title:

HEAT EXCHANGER USING NANO FLUIDOriginal File Name Searched:

Article_11_Vol_III_issue_IV_2012.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |