PDF Publication Title:

Text from PDF Page: 004

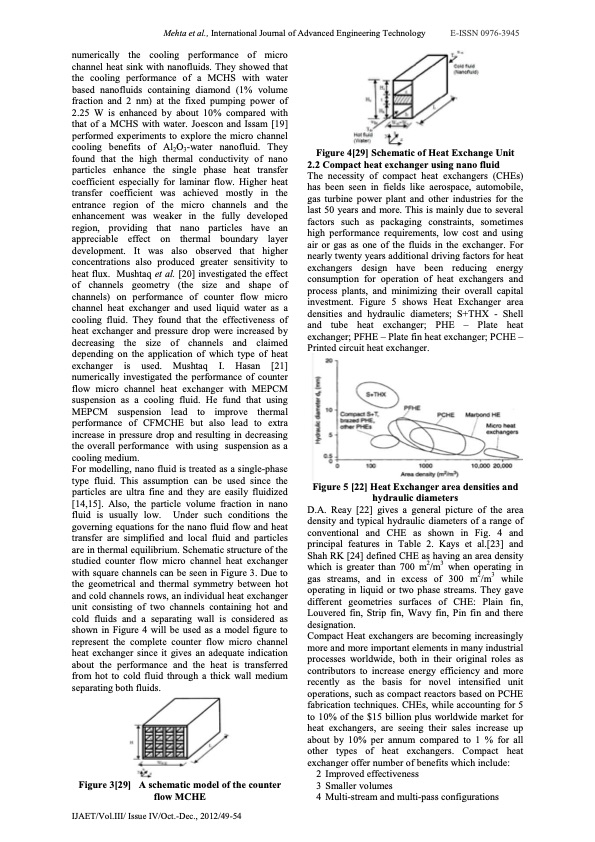

Mehta et al., International Journal of Advanced Engineering Technology E-ISSN 0976-3945 numerically the cooling performance of micro channel heat sink with nanofluids. They showed that the cooling performance of a MCHS with water based nanofluids containing diamond (1% volume fraction and 2 nm) at the fixed pumping power of 2.25 W is enhanced by about 10% compared with that of a MCHS with water. Joescon and Issam [19] performed experiments to explore the micro channel cooling benefits of Al2O3-water nanofluid. They found that the high thermal conductivity of nano particles enhance the single phase heat transfer coefficient especially for laminar flow. Higher heat transfer coefficient was achieved mostly in the entrance region of the micro channels and the enhancement was weaker in the fully developed region, providing that nano particles have an appreciable effect on thermal boundary layer development. It was also observed that higher concentrations also produced greater sensitivity to heat flux. Mushtaq et al. [20] investigated the effect of channels geometry (the size and shape of channels) on performance of counter flow micro channel heat exchanger and used liquid water as a cooling fluid. They found that the effectiveness of heat exchanger and pressure drop were increased by decreasing the size of channels and claimed depending on the application of which type of heat exchanger is used. Mushtaq I. Hasan [21] numerically investigated the performance of counter flow micro channel heat exchanger with MEPCM suspension as a cooling fluid. He fund that using MEPCM suspension lead to improve thermal performance of CFMCHE but also lead to extra increase in pressure drop and resulting in decreasing the overall performance with using suspension as a cooling medium. For modelling, nano fluid is treated as a single-phase type fluid. This assumption can be used since the particles are ultra fine and they are easily fluidized [14,15]. Also, the particle volume fraction in nano fluid is usually low. Under such conditions the governing equations for the nano fluid flow and heat transfer are simplified and local fluid and particles are in thermal equilibrium. Schematic structure of the studied counter flow micro channel heat exchanger with square channels can be seen in Figure 3. Due to the geometrical and thermal symmetry between hot and cold channels rows, an individual heat exchanger unit consisting of two channels containing hot and cold fluids and a separating wall is considered as shown in Figure 4 will be used as a model figure to represent the complete counter flow micro channel heat exchanger since it gives an adequate indication about the performance and the heat is transferred from hot to cold fluid through a thick wall medium separating both fluids. Figure 4[29] Schematic of Heat Exchange Unit 2.2 Compact heat exchanger using nano fluid The necessity of compact heat exchangers (CHEs) has been seen in fields like aerospace, automobile, gas turbine power plant and other industries for the last 50 years and more. This is mainly due to several factors such as packaging constraints, sometimes high performance requirements, low cost and using air or gas as one of the fluids in the exchanger. For nearly twenty years additional driving factors for heat exchangers design have been reducing energy consumption for operation of heat exchangers and process plants, and minimizing their overall capital investment. Figure 5 shows Heat Exchanger area densities and hydraulic diameters; S+THX - Shell and tube heat exchanger; PHE – Plate heat exchanger; PFHE – Plate fin heat exchanger; PCHE – Printed circuit heat exchanger. Figure 5 [22] Heat Exchanger area densities and hydraulic diameters D.A. Reay [22] gives a general picture of the area density and typical hydraulic diameters of a range of conventional and CHE as shown in Fig. 4 and principal features in Table 2. Kays et al.[23] and Shah RK [24] defined CHE as having an area density which is greater than 700 m2/m3 when operating in gas streams, and in excess of 300 m2/m3 while operating in liquid or two phase streams. They gave different geometries surfaces of CHE: Plain fin, Louvered fin, Strip fin, Wavy fin, Pin fin and there designation. Compact Heat exchangers are becoming increasingly more and more important elements in many industrial processes worldwide, both in their original roles as contributors to increase energy efficiency and more recently as the basis for novel intensified unit operations, such as compact reactors based on PCHE fabrication techniques. CHEs, while accounting for 5 to 10% of the $15 billion plus worldwide market for heat exchangers, are seeing their sales increase up about by 10% per annum compared to 1 % for all other types of heat exchangers. Compact heat exchanger offer number of benefits which include: 2 Improved effectiveness 3 Smaller volumes 4 Multi-stream and multi-pass configurations Figure 3[29] A schematic model of the counter flow MCHE IJAET/Vol.III/ Issue IV/Oct.-Dec., 2012/49-54PDF Image | HEAT EXCHANGER USING NANO FLUID

PDF Search Title:

HEAT EXCHANGER USING NANO FLUIDOriginal File Name Searched:

Article_11_Vol_III_issue_IV_2012.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |