PDF Publication Title:

Text from PDF Page: 006

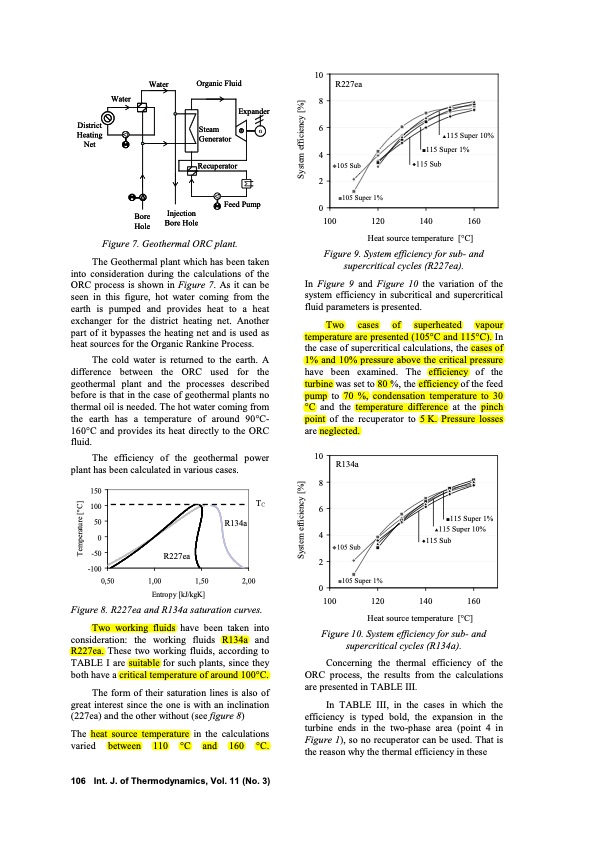

R227ea 115 Super 10% 115 Super 1% 105 Sub 115 Sub 105 Super 1% Water Organic Fluid Expander 10 8 6 4 2 0 100 Water District Heating Net Steam Generator Recuperator G Bore Hole Injection Bore Hole 120 140 160 Heat source temperature [°C] Figure 7. Geothermal ORC plant. The Geothermal plant which has been taken into consideration during the calculations of the ORC process is shown in Figure 7. As it can be seen in this figure, hot water coming from the earth is pumped and provides heat to a heat exchanger for the district heating net. Another part of it bypasses the heating net and is used as heat sources for the Organic Rankine Process. The cold water is returned to the earth. A difference between the ORC used for the geothermal plant and the processes described before is that in the case of geothermal plants no thermal oil is needed. The hot water coming from the earth has a temperature of around 90°C- 160°C and provides its heat directly to the ORC fluid. The efficiency of the geothermal power plant has been calculated in various cases. Figure 9. System efficiency for sub- and supercritical cycles (R227ea). In Figure 9 and Figure 10 the variation of the system efficiency in subcritical and supercritical fluid parameters is presented. Two cases of superheated vapour temperature are presented (105°C and 115°C). In the case of supercritical calculations, the cases of 1% and 10% pressure above the critical pressure have been examined. The efficiency of the turbine was set to 80 %, the efficiency of the feed pump to 70 %, condensation temperature to 30 °C and the temperature difference at the pinch point of the recuperator to 5 K. Pressure losses are neglected. 10 8 6 4 2 0 100 120 Heat source temperature [°C] Figure 10. System efficiency for sub- and supercritical cycles (R134a). Concerning the thermal efficiency of the ORC process, the results from the calculations are presented in TABLE III. In TABLE III, in the cases in which the efficiency is typed bold, the expansion in the turbine ends in the two-phase area (point 4 in Figure 1), so no recuperator can be used. That is the reason why the thermal efficiency in these Feed Pump R134a 115 Super 1% 115 Super 10% 105 Sub 115 Sub 105 Super 1% 150 100 50 0 -50 TC R227ea R134a -100 0,50 1,00 1,50 2,00 Entropy [kJ/kgK] 140 160 Figure 8. R227ea and R134a saturation curves. Two working fluids have been taken into consideration: the working fluids R134a and R227ea. These two working fluids, according to TABLE I are suitable for such plants, since they both have a critical temperature of around 100°C. The form of their saturation lines is also of great interest since the one is with an inclination (227ea) and the other without (see figure 8) The heat source temperature in the calculations varied between 110 °C and 160 °C. 106 Int. J. of Thermodynamics, Vol. 11 (No. 3) Temperature [°C] System efficiency [%] System efficiency [%]PDF Image | Supercritical Fluid Parameters in Organic Rankine Cycle Applications

PDF Search Title:

Supercritical Fluid Parameters in Organic Rankine Cycle ApplicationsOriginal File Name Searched:

2008___Schuster__Supercritical_Fluid_Parameters_in_Organic_Rankine_Cycle_applications.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |