PDF Publication Title:

Text from PDF Page: 004

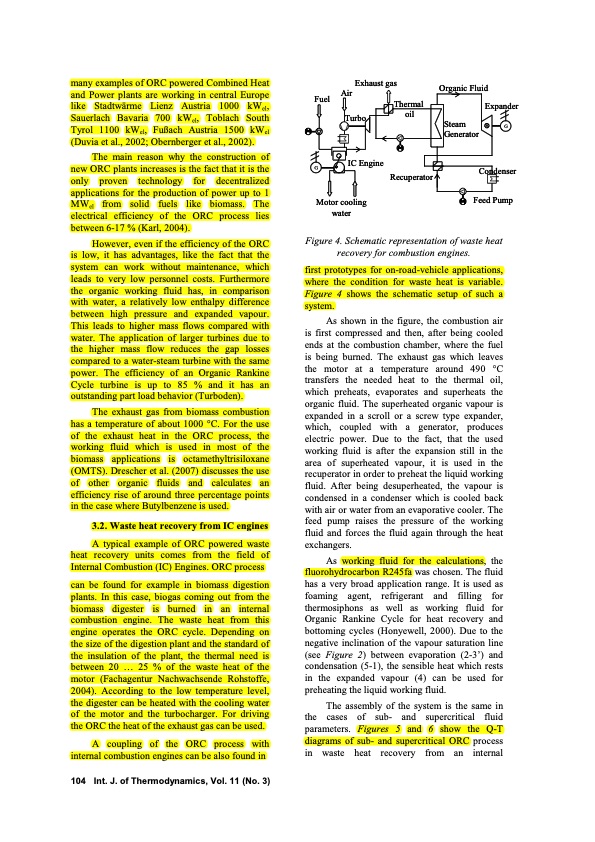

many examples of ORC powered Combined Heat and Power plants are working in central Europe like Stadtwärme Lienz Austria 1000 kWel, Sauerlach Bavaria 700 kWel, Toblach South Tyrol 1100 kWel, Fußach Austria 1500 kWel (Duvia et al., 2002; Obernberger et al., 2002). The main reason why the construction of new ORC plants increases is the fact that it is the only proven technology for decentralized applications for the production of power up to 1 MWel from solid fuels like biomass. The electrical efficiency of the ORC process lies between 6-17 % (Karl, 2004). However, even if the efficiency of the ORC is low, it has advantages, like the fact that the system can work without maintenance, which leads to very low personnel costs. Furthermore the organic working fluid has, in comparison with water, a relatively low enthalpy difference between high pressure and expanded vapour. This leads to higher mass flows compared with water. The application of larger turbines due to the higher mass flow reduces the gap losses compared to a water-steam turbine with the same power. The efficiency of an Organic Rankine Cycle turbine is up to 85 % and it has an outstanding part load behavior (Turboden). The exhaust gas from biomass combustion has a temperature of about 1000 °C. For the use of the exhaust heat in the ORC process, the working fluid which is used in most of the biomass applications is octamethyltrisiloxane (OMTS). Drescher et al. (2007) discusses the use of other organic fluids and calculates an efficiency rise of around three percentage points in the case where Butylbenzene is used. 3.2. Waste heat recovery from IC engines A typical example of ORC powered waste heat recovery units comes from the field of Internal Combustion (IC) Engines. ORC process can be found for example in biomass digestion plants. In this case, biogas coming out from the biomass digester is burned in an internal combustion engine. The waste heat from this engine operates the ORC cycle. Depending on the size of the digestion plant and the standard of the insulation of the plant, the thermal need is between 20 ... 25 % of the waste heat of the motor (Fachagentur Nachwachsende Rohstoffe, 2004). According to the low temperature level, the digester can be heated with the cooling water of the motor and the turbocharger. For driving the ORC the heat of the exhaust gas can be used. A coupling of the ORC process with internal combustion engines can be also found in Exhaust gas Organic Fluid Expander Fuel Air Turbo Thermal oil Steam Generator G G IC Engine Recuperator Condenser Feed Pump 104 Int. J. of Thermodynamics, Vol. 11 (No. 3) Motor cooling water Figure 4. Schematic representation of waste heat recovery for combustion engines. first prototypes for on-road-vehicle applications, where the condition for waste heat is variable. Figure 4 shows the schematic setup of such a system. As shown in the figure, the combustion air is first compressed and then, after being cooled ends at the combustion chamber, where the fuel is being burned. The exhaust gas which leaves the motor at a temperature around 490 °C transfers the needed heat to the thermal oil, which preheats, evaporates and superheats the organic fluid. The superheated organic vapour is expanded in a scroll or a screw type expander, which, coupled with a generator, produces electric power. Due to the fact, that the used working fluid is after the expansion still in the area of superheated vapour, it is used in the recuperator in order to preheat the liquid working fluid. After being desuperheated, the vapour is condensed in a condenser which is cooled back with air or water from an evaporative cooler. The feed pump raises the pressure of the working fluid and forces the fluid again through the heat exchangers. As working fluid for the calculations, the fluorohydrocarbon R245fa was chosen. The fluid has a very broad application range. It is used as foaming agent, refrigerant and filling for thermosiphons as well as working fluid for Organic Rankine Cycle for heat recovery and bottoming cycles (Honyewell, 2000). Due to the negative inclination of the vapour saturation line (see Figure 2) between evaporation (2-3’) and condensation (5-1), the sensible heat which rests in the expanded vapour (4) can be used for preheating the liquid working fluid. The assembly of the system is the same in the cases of sub- and supercritical fluid parameters. Figures 5 and 6 show the Q-T diagrams of sub- and supercritical ORC process in waste heat recovery from an internalPDF Image | Supercritical Fluid Parameters in Organic Rankine Cycle Applications

PDF Search Title:

Supercritical Fluid Parameters in Organic Rankine Cycle ApplicationsOriginal File Name Searched:

2008___Schuster__Supercritical_Fluid_Parameters_in_Organic_Rankine_Cycle_applications.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |