PDF Publication Title:

Text from PDF Page: 002

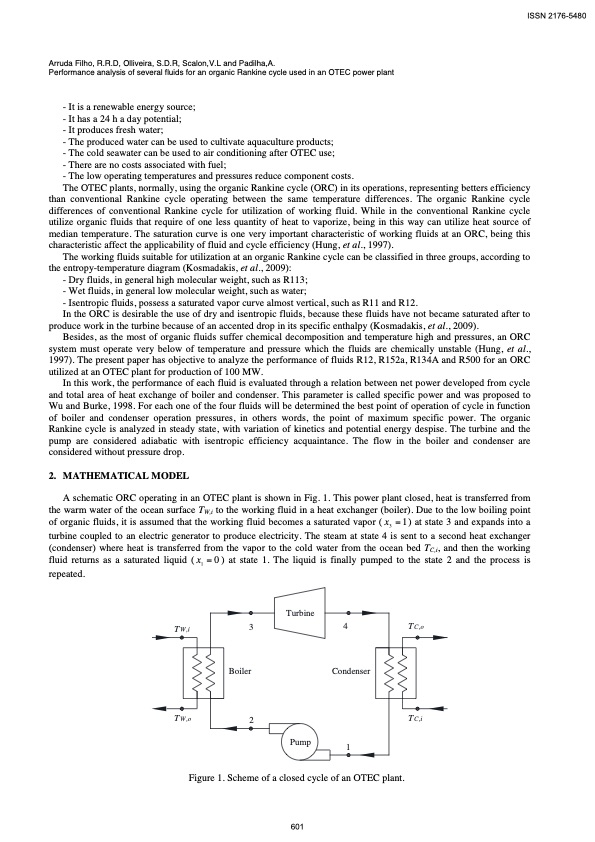

Arruda Filho, R.R.D, Olliveira, S.D.R, Scalon,V.L and Padilha,A. Performance analysis of several fluids for an organic Rankine cycle used in an OTEC power plant - It is a renewable energy source; - It has a 24 h a day potential; - It produces fresh water; - The produced water can be used to cultivate aquaculture products; - The cold seawater can be used to air conditioning after OTEC use; - There are no costs associated with fuel; - The low operating temperatures and pressures reduce component costs. The OTEC plants, normally, using the organic Rankine cycle (ORC) in its operations, representing betters efficiency than conventional Rankine cycle operating between the same temperature differences. The organic Rankine cycle differences of conventional Rankine cycle for utilization of working fluid. While in the conventional Rankine cycle utilize organic fluids that require of one less quantity of heat to vaporize, being in this way can utilize heat source of median temperature. The saturation curve is one very important characteristic of working fluids at an ORC, being this characteristic affect the applicability of fluid and cycle efficiency (Hung, et al., 1997). The working fluids suitable for utilization at an organic Rankine cycle can be classified in three groups, according to the entropy-temperature diagram (Kosmadakis, et al., 2009): - Dry fluids, in general high molecular weight, such as R113; - Wet fluids, in general low molecular weight, such as water; - Isentropic fluids, possess a saturated vapor curve almost vertical, such as R11 and R12. In the ORC is desirable the use of dry and isentropic fluids, because these fluids have not became saturated after to produce work in the turbine because of an accented drop in its specific enthalpy (Kosmadakis, et al., 2009). Besides, as the most of organic fluids suffer chemical decomposition and temperature high and pressures, an ORC system must operate very below of temperature and pressure which the fluids are chemically unstable (Hung, et al., 1997). The present paper has objective to analyze the performance of fluids R12, R152a, R134A and R500 for an ORC utilized at an OTEC plant for production of 100 MW. In this work, the performance of each fluid is evaluated through a relation between net power developed from cycle and total area of heat exchange of boiler and condenser. This parameter is called specific power and was proposed to Wu and Burke, 1998. For each one of the four fluids will be determined the best point of operation of cycle in function of boiler and condenser operation pressures, in others words, the point of maximum specific power. The organic Rankine cycle is analyzed in steady state, with variation of kinetics and potential energy despise. The turbine and the pump are considered adiabatic with isentropic efficiency acquaintance. The flow in the boiler and condenser are considered without pressure drop. 2. MATHEMATICAL MODEL A schematic ORC operating in an OTEC plant is shown in Fig. 1. This power plant closed, heat is transferred from the warm water of the ocean surface TW,i to the working fluid in a heat exchanger (boiler). Due to the low boiling point of organic fluids, it is assumed that the working fluid becomes a saturated vapor ( x3 = 1 ) at state 3 and expands into a turbine coupled to an electric generator to produce electricity. The steam at state 4 is sent to a second heat exchanger (condenser) where heat is transferred from the vapor to the cold water from the ocean bed TC,i, and then the working fluid returns as a saturated liquid ( x1 = 0 ) at state 1. The liquid is finally pumped to the state 2 and the process is repeated. ISSN 2176-5480 TW,i Turbine 3 4 TC,o Boiler Condenser 1 TW,o 2 TC,i Pump Figure 1. Scheme of a closed cycle of an OTEC plant. 601PDF Image | PERFORMANCE ANALYSIS OF FLUIDS R12, R152A, R134A AND R500 FOR AN ORGANIC RANKINE CYCLE USED IN AN OTEC POWER PLANT

PDF Search Title:

PERFORMANCE ANALYSIS OF FLUIDS R12, R152A, R134A AND R500 FOR AN ORGANIC RANKINE CYCLE USED IN AN OTEC POWER PLANTOriginal File Name Searched:

140.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |