PDF Publication Title:

Text from PDF Page: 002

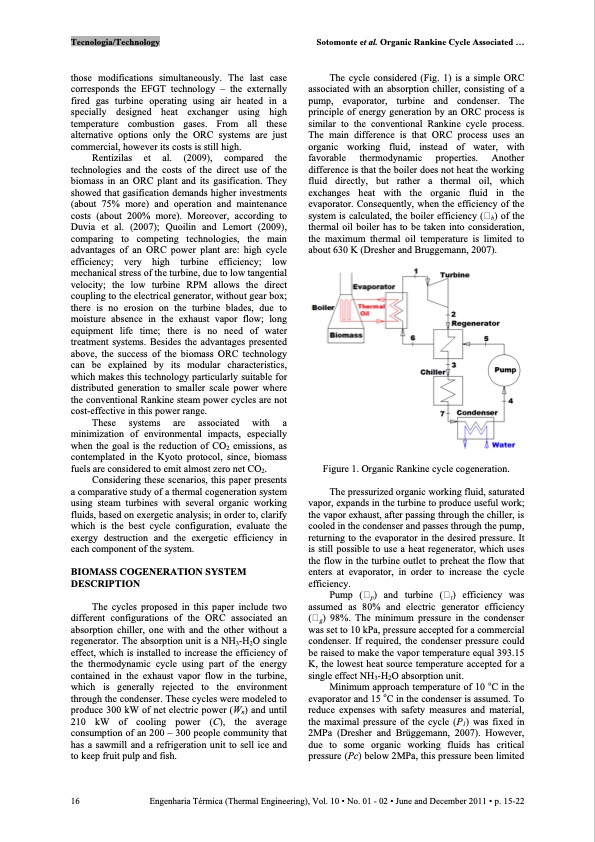

Tecnologia/Technology Sotomonte et al. Organic Rankine Cycle Associated ... those modifications simultaneously. The last case corresponds the EFGT technology – the externally fired gas turbine operating using air heated in a specially designed heat exchanger using high temperature combustion gases. From all these alternative options only the ORC systems are just commercial, however its costs is still high. Rentizilas et al. (2009), compared the technologies and the costs of the direct use of the biomass in an ORC plant and its gasification. They showed that gasification demands higher investments (about 75% more) and operation and maintenance costs (about 200% more). Moreover, according to Duvia et al. (2007); Quoilin and Lemort (2009), comparing to competing technologies, the main advantages of an ORC power plant are: high cycle efficiency; very high turbine efficiency; low mechanical stress of the turbine, due to low tangential velocity; the low turbine RPM allows the direct coupling to the electrical generator, without gear box; there is no erosion on the turbine blades, due to moisture absence in the exhaust vapor flow; long equipment life time; there is no need of water treatment systems. Besides the advantages presented above, the success of the biomass ORC technology can be explained by its modular characteristics, which makes this technology particularly suitable for distributed generation to smaller scale power where the conventional Rankine steam power cycles are not cost-effective in this power range. These systems are associated with a minimization of environmental impacts, especially when the goal is the reduction of CO2 emissions, as contemplated in the Kyoto protocol, since, biomass fuels are considered to emit almost zero net CO2. Considering these scenarios, this paper presents a comparative study of a thermal cogeneration system using steam turbines with several organic working fluids, based on exergetic analysis; in order to, clarify which is the best cycle configuration, evaluate the exergy destruction and the exergetic efficiency in each component of the system. BIOMASS COGENERATION SYSTEM DESCRIPTION The cycles proposed in this paper include two different configurations of the ORC associated an absorption chiller, one with and the other without a regenerator. The absorption unit is a NH3-H2O single effect, which is installed to increase the efficiency of the thermodynamic cycle using part of the energy contained in the exhaust vapor flow in the turbine, which is generally rejected to the environment through the condenser. These cycles were modeled to produce 300 kW of net electric power (Wn) and until 210 kW of cooling power (C), the average consumption of an 200 – 300 people community that has a sawmill and a refrigeration unit to sell ice and to keep fruit pulp and fish. The cycle considered (Fig. 1) is a simple ORC associated with an absorption chiller, consisting of a pump, evaporator, turbine and condenser. The principle of energy generation by an ORC process is similar to the conventional Rankine cycle process. The main difference is that ORC process uses an organic working fluid, instead of water, with favorable thermodynamic properties. Another difference is that the boiler does not heat the working fluid directly, but rather a thermal oil, which exchanges heat with the organic fluid in the evaporator. Consequently, when the efficiency of the system is calculated, the boiler efficiency (�b) of the thermal oil boiler has to be taken into consideration, the maximum thermal oil temperature is limited to about 630 K (Dresher and Bruggemann, 2007). Figure 1. Organic Rankine cycle cogeneration. The pressurized organic working fluid, saturated vapor, expands in the turbine to produce useful work; the vapor exhaust, after passing through the chiller, is cooled in the condenser and passes through the pump, returning to the evaporator in the desired pressure. It is still possible to use a heat regenerator, which uses the flow in the turbine outlet to preheat the flow that enters at evaporator, in order to increase the cycle efficiency. Pump (�p) and turbine (�t) efficiency was assumed as 80% and electric generator efficiency (�g) 98%. The minimum pressure in the condenser was set to 10 kPa, pressure accepted for a commercial condenser. If required, the condenser pressure could be raised to make the vapor temperature equal 393.15 K, the lowest heat source temperature accepted for a single effect NH3-H2O absorption unit. Minimum approach temperature of 10 oC in the evaporator and 15 oC in the condenser is assumed. To reduce expenses with safety measures and material, the maximal pressure of the cycle (P1) was fixed in 2MPa (Dresher and Brüggemann, 2007). However, due to some organic working fluids has critical pressure (Pc) below 2MPa, this pressure been limited 16 Engenharia Térmica (Thermal Engineering), Vol. 10 • No. 01 - 02 • June and December 2011 • p. 15-22PDF Image | ORGANIC RANKINE CYCLE ASSOCIATED WITH AN ABSORPTION CHILLER FOR BIOMASS APPLICATIONS

PDF Search Title:

ORGANIC RANKINE CYCLE ASSOCIATED WITH AN ABSORPTION CHILLER FOR BIOMASS APPLICATIONSOriginal File Name Searched:

228_2012.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |