PDF Publication Title:

Text from PDF Page: 003

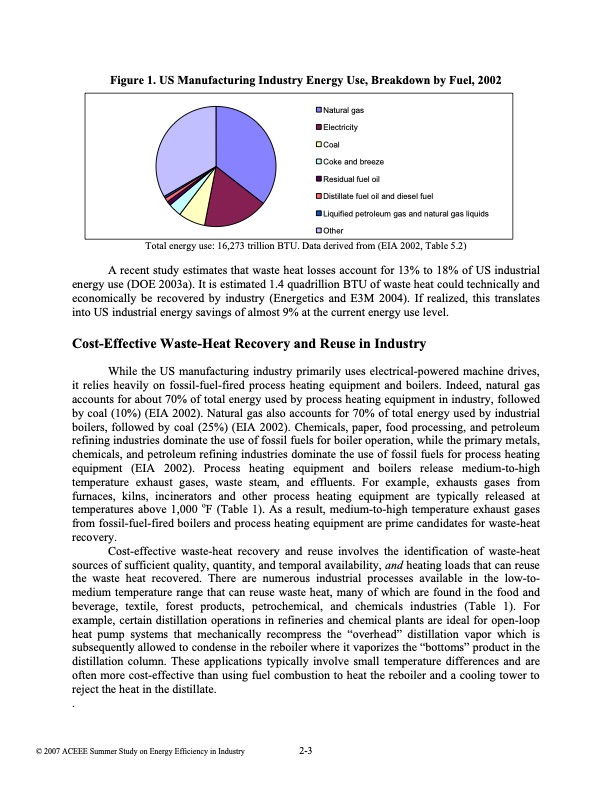

Figure 1. US Manufacturing Industry Energy Use, Breakdown by Fuel, 2002 Natural gas Electricity Coal Coke and breeze Residual fuel oil Distillate fuel oil and diesel fuel Liquified petroleum gas and natural gas liquids Other Total energy use: 16,273 trillion BTU. Data derived from (EIA 2002, Table 5.2) A recent study estimates that waste heat losses account for 13% to 18% of US industrial energy use (DOE 2003a). It is estimated 1.4 quadrillion BTU of waste heat could technically and economically be recovered by industry (Energetics and E3M 2004). If realized, this translates into US industrial energy savings of almost 9% at the current energy use level. Cost-Effective Waste-Heat Recovery and Reuse in Industry While the US manufacturing industry primarily uses electrical-powered machine drives, it relies heavily on fossil-fuel-fired process heating equipment and boilers. Indeed, natural gas accounts for about 70% of total energy used by process heating equipment in industry, followed by coal (10%) (EIA 2002). Natural gas also accounts for 70% of total energy used by industrial boilers, followed by coal (25%) (EIA 2002). Chemicals, paper, food processing, and petroleum refining industries dominate the use of fossil fuels for boiler operation, while the primary metals, chemicals, and petroleum refining industries dominate the use of fossil fuels for process heating equipment (EIA 2002). Process heating equipment and boilers release medium-to-high temperature exhaust gases, waste steam, and effluents. For example, exhausts gases from furnaces, kilns, incinerators and other process heating equipment are typically released at temperatures above 1,000 oF (Table 1). As a result, medium-to-high temperature exhaust gases from fossil-fuel-fired boilers and process heating equipment are prime candidates for waste-heat recovery. Cost-effective waste-heat recovery and reuse involves the identification of waste-heat sources of sufficient quality, quantity, and temporal availability, and heating loads that can reuse the waste heat recovered. There are numerous industrial processes available in the low-to- medium temperature range that can reuse waste heat, many of which are found in the food and beverage, textile, forest products, petrochemical, and chemicals industries (Table 1). For example, certain distillation operations in refineries and chemical plants are ideal for open-loop heat pump systems that mechanically recompress the “overhead” distillation vapor which is subsequently allowed to condense in the reboiler where it vaporizes the “bottoms” product in the distillation column. These applications typically involve small temperature differences and are often more cost-effective than using fuel combustion to heat the reboiler and a cooling tower to reject the heat in the distillate. . © 2007 ACEEE Summer Study on Energy Efficiency in Industry 2-3PDF Image | Industrial Waste Heat Recovery Benefits and Recent Advancements in Technology and Applications

PDF Search Title:

Industrial Waste Heat Recovery Benefits and Recent Advancements in Technology and ApplicationsOriginal File Name Searched:

05_2_048.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |