PDF Publication Title:

Text from PDF Page: 003

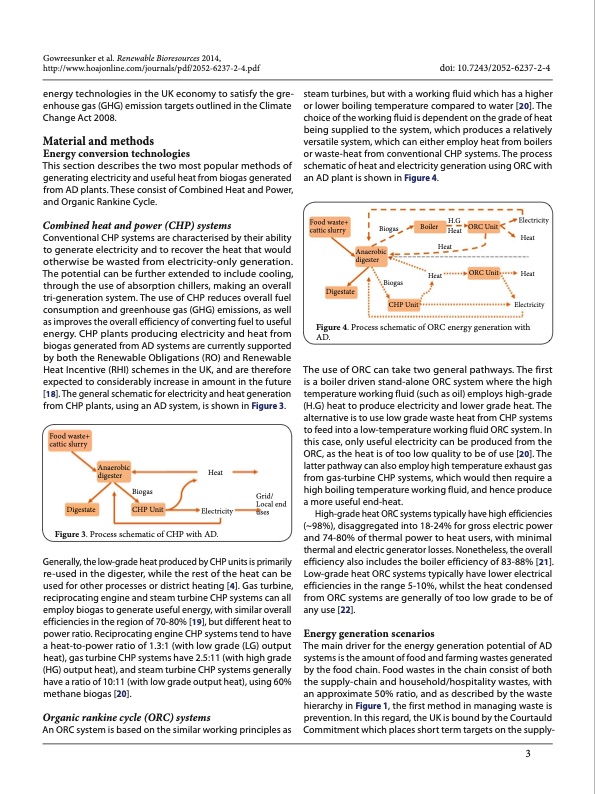

Gowreesunker et al. Renewable Bioresources 2014, http://www.hoajonline.com/journals/pdf/2052-6237-2-4.pdf energy technologies in the UK economy to satisfy the gre- enhouse gas (GHG) emission targets outlined in the Climate Change Act 2008. Material and methods Energy conversion technologies This section describes the two most popular methods of generating electricity and useful heat from biogas generated from AD plants. These consist of Combined Heat and Power, and Organic Rankine Cycle. Combined heat and power (CHP) systems Conventional CHP systems are characterised by their ability to generate electricity and to recover the heat that would otherwise be wasted from electricity-only generation. The potential can be further extended to include cooling, through the use of absorption chillers, making an overall tri-generation system. The use of CHP reduces overall fuel consumption and greenhouse gas (GHG) emissions, as well as improves the overall efficiency of converting fuel to useful energy. CHP plants producing electricity and heat from biogas generated from AD systems are currently supported by both the Renewable Obligations (RO) and Renewable Heat Incentive (RHI) schemes in the UK, and are therefore expected to considerably increase in amount in the future [18]. The general schematic for electricity and heat generation from CHP plants, using an AD system, is shown in Figure 3. doi: 10.7243/2052-6237-2-4 steam turbines, but with a working fluid which has a higher or lower boiling temperature compared to water [20]. The choice of the working fluid is dependent on the grade of heat being supplied to the system, which produces a relatively versatile system, which can either employ heat from boilers or waste-heat from conventional CHP systems. The process schematic of heat and electricity generation using ORC with an AD plant is shown in Figure 4. Food waste+ cattic slurry Anaerobic digester Heat Local end Electricity uses Figure 4. Process schematic of ORC energy generation with AD. The use of ORC can take two general pathways. The first is a boiler driven stand-alone ORC system where the high temperature working fluid (such as oil) employs high-grade (H.G) heat to produce electricity and lower grade heat. The alternative is to use low grade waste heat from CHP systems to feed into a low-temperature working fluid ORC system. In this case, only useful electricity can be produced from the ORC, as the heat is of too low quality to be of use [20]. The latter pathway can also employ high temperature exhaust gas from gas-turbine CHP systems, which would then require a high boiling temperature working fluid, and hence produce a more useful end-heat. High-grade heat ORC systems typically have high efficiencies (~98%), disaggregated into 18-24% for gross electric power and 74-80% of thermal power to heat users, with minimal thermal and electric generator losses. Nonetheless, the overall efficiency also includes the boiler efficiency of 83-88% [21]. Low-grade heat ORC systems typically have lower electrical efficiencies in the range 5-10%, whilst the heat condensed from ORC systems are generally of too low grade to be of any use [22]. Energy generation scenarios The main driver for the energy generation potential of AD systems is the amount of food and farming wastes generated by the food chain. Food wastes in the chain consist of both the supply-chain and household/hospitality wastes, with an approximate 50% ratio, and as described by the waste hierarchy in Figure 1, the first method in managing waste is prevention. In this regard, the UK is bound by the Courtauld Commitment which places short term targets on the supply- Biogas CHP Unit Grid/ Digestate Figure 3. Process schematic of CHP with AD. Generally, the low-grade heat produced by CHP units is primarily re-used in the digester, while the rest of the heat can be used for other processes or district heating [4]. Gas turbine, reciprocating engine and steam turbine CHP systems can all employ biogas to generate useful energy, with similar overall efficiencies in the region of 70-80% [19], but different heat to power ratio. Reciprocating engine CHP systems tend to have a heat-to-power ratio of 1.3:1 (with low grade (LG) output heat), gas turbine CHP systems have 2.5:11 (with high grade (HG) output heat), and steam turbine CHP systems generally have a ratio of 10:11 (with low grade output heat), using 60% methane biogas [20]. Organic rankine cycle (ORC) systems An ORC system is based on the similar working principles as Food waste+ cattic slurry Digestate Biogas Anaerobic digester Boiler H.G Heat Heat Heat ORC Unit Electricity Heat Biogas CHP Unit ORC Unit Heat Electricity 3PDF Image | Energy generation potential of anaerobic digestion from the food and farming wastes of the UK food chain

PDF Search Title:

Energy generation potential of anaerobic digestion from the food and farming wastes of the UK food chainOriginal File Name Searched:

2052_6237_2_4.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |