PDF Publication Title:

Text from PDF Page: 002

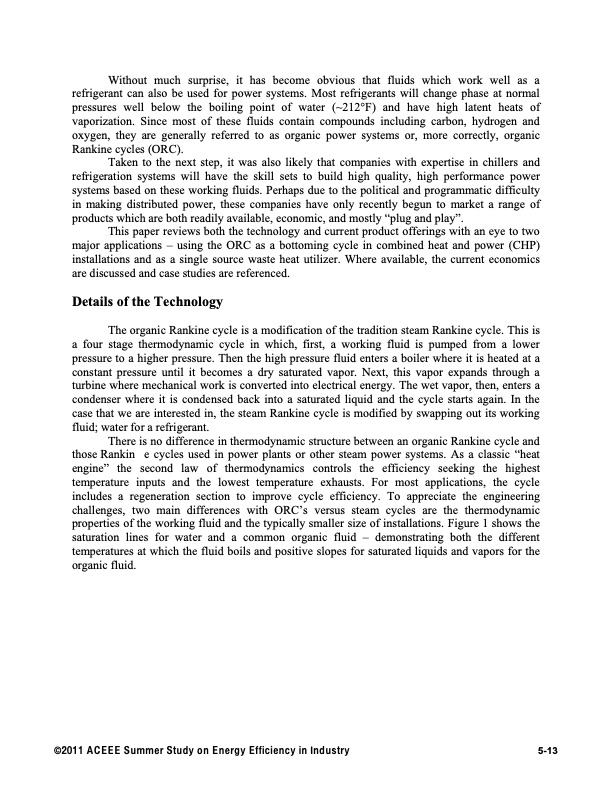

Without much surprise, it has become obvious that fluids which work well as a refrigerant can also be used for power systems. Most refrigerants will change phase at normal pressures well below the boiling point of water (~212°F) and have high latent heats of vaporization. Since most of these fluids contain compounds including carbon, hydrogen and oxygen, they are generally referred to as organic power systems or, more correctly, organic Rankine cycles (ORC). Taken to the next step, it was also likely that companies with expertise in chillers and refrigeration systems will have the skill sets to build high quality, high performance power systems based on these working fluids. Perhaps due to the political and programmatic difficulty in making distributed power, these companies have only recently begun to market a range of products which are both readily available, economic, and mostly “plug and play”. This paper reviews both the technology and current product offerings with an eye to two major applications – using the ORC as a bottoming cycle in combined heat and power (CHP) installations and as a single source waste heat utilizer. Where available, the current economics are discussed and case studies are referenced. Details of the Technology The organic Rankine cycle is a modification of the tradition steam Rankine cycle. This is a four stage thermodynamic cycle in which, first, a working fluid is pumped from a lower pressure to a higher pressure. Then the high pressure fluid enters a boiler where it is heated at a constant pressure until it becomes a dry saturated vapor. Next, this vapor expands through a turbine where mechanical work is converted into electrical energy. The wet vapor, then, enters a condenser where it is condensed back into a saturated liquid and the cycle starts again. In the case that we are interested in, the steam Rankine cycle is modified by swapping out its working fluid; water for a refrigerant. There is no difference in thermodynamic structure between an organic Rankine cycle and those Rankin e cycles used in power plants or other steam power systems. As a classic “heat engine” the second law of thermodynamics controls the efficiency seeking the highest temperature inputs and the lowest temperature exhausts. For most applications, the cycle includes a regeneration section to improve cycle efficiency. To appreciate the engineering challenges, two main differences with ORC’s versus steam cycles are the thermodynamic properties of the working fluid and the typically smaller size of installations. Figure 1 shows the saturation lines for water and a common organic fluid – demonstrating both the different temperatures at which the fluid boils and positive slopes for saturated liquids and vapors for the organic fluid. ©2011 ACEEE Summer Study on Energy Efficiency in Industry 5-13PDF Image | Economic Implementation of the Organic Rankine Cycle in Industry

PDF Search Title:

Economic Implementation of the Organic Rankine Cycle in IndustryOriginal File Name Searched:

0085_000077.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |