PDF Publication Title:

Text from PDF Page: 002

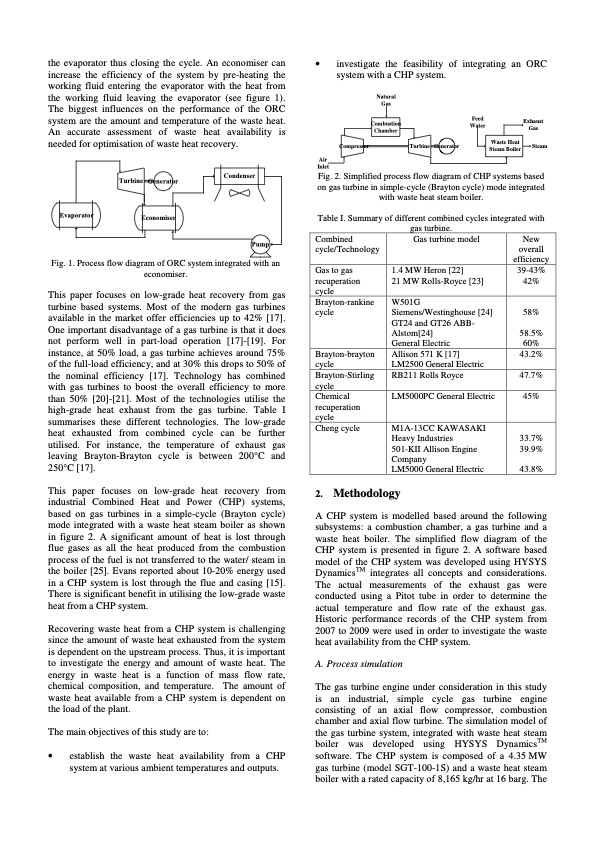

the evaporator thus closing the cycle. An economiser can increase the efficiency of the system by pre-heating the working fluid entering the evaporator with the heat from the working fluid leaving the evaporator (see figure 1). The biggest influences on the performance of the ORC system are the amount and temperature of the waste heat. An accurate assessment of waste heat availability is needed for optimisation of waste heat recovery. • Air Inlet investigate the feasibility of integrating an ORC system with a CHP system. Compressor Turbine Generator Natural Gas Combustion Chamber Feed Water Exhaust Gas Steam Evaporator Turbine Generator Economiser Fig. 2. Simplified process flow diagram of CHP systems based on gas turbine in simple-cycle (Brayton cycle) mode integrated with waste heat steam boiler. Table I. Summary of different combined cycles integrated with gas turbine. Fig. 1. Process flow diagram of ORC system integrated with an economiser. This paper focuses on low-grade heat recovery from gas turbine based systems. Most of the modern gas turbines available in the market offer efficiencies up to 42% [17]. One important disadvantage of a gas turbine is that it does not perform well in part-load operation [17]-[19]. For instance, at 50% load, a gas turbine achieves around 75% of the full-load efficiency, and at 30% this drops to 50% of the nominal efficiency [17]. Technology has combined with gas turbines to boost the overall efficiency to more than 50% [20]-[21]. Most of the technologies utilise the high-grade heat exhaust from the gas turbine. Table I summarises these different technologies. The low-grade heat exhausted from combined cycle can be further utilised. For instance, the temperature of exhaust gas leaving Brayton-Brayton cycle is between 200°C and 250°C [17]. This paper focuses on low-grade heat recovery from industrial Combined Heat and Power (CHP) systems, based on gas turbines in a simple-cycle (Brayton cycle) mode integrated with a waste heat steam boiler as shown in figure 2. A significant amount of heat is lost through flue gases as all the heat produced from the combustion process of the fuel is not transferred to the water/ steam in the boiler [25]. Evans reported about 10-20% energy used in a CHP system is lost through the flue and casing [15]. There is significant benefit in utilising the low-grade waste heat from a CHP system. Recovering waste heat from a CHP system is challenging since the amount of waste heat exhausted from the system is dependent on the upstream process. Thus, it is important to investigate the energy and amount of waste heat. The energy in waste heat is a function of mass flow rate, chemical composition, and temperature. The amount of waste heat available from a CHP system is dependent on the load of the plant. The main objectives of this study are to: • establish the waste heat availability from a CHP system at various ambient temperatures and outputs. 2. Methodology Pump Combined cycle/Technology Gas to gas recuperation cycle Brayton-brayton cycle Brayton-Stirling cycle Chemical recuperation cycle Gas turbine model 1.4 MW Heron [22] 21 MW Rolls-Royce [23] Allison 571 K [17] LM2500 General Electric RB211 Rolls Royce LM5000PC General Electric New overall efficiency 39-43% 42% 43.2% 47.7% 45% Brayton-rankine cycle W501G Siemens/Westinghouse [24] GT24 and GT26 ABB- Alstom[24] General Electric 58% 58.5% 60% Cheng cycle M1A-13CC KAWASAKI Heavy Industries 501-KII Allison Engine Company LM5000 General Electric 33.7% 39.9% 43.8% A CHP system is modelled based around the following subsystems: a combustion chamber, a gas turbine and a waste heat boiler. The simplified flow diagram of the CHP system is presented in figure 2. A software based model of the CHP system was developed using HYSYS DynamicsTM integrates all concepts and considerations. The actual measurements of the exhaust gas were conducted using a Pitot tube in order to determine the actual temperature and flow rate of the exhaust gas. Historic performance records of the CHP system from 2007 to 2009 were used in order to investigate the waste heat availability from the CHP system. A. Process simulation The gas turbine engine under consideration in this study is an industrial, simple cycle gas turbine engine consisting of an axial flow compressor, combustion chamber and axial flow turbine. The simulation model of the gas turbine system, integrated with waste heat steam boiler was developed using HYSYS DynamicsTM software. The CHP system is composed of a 4.35 MW gas turbine (model SGT-100-1S) and a waste heat steam boiler with a rated capacity of 8,165 kg/hr at 16 barg. The Waste Heat Steam Boiler CondenserPDF Image | Assessment and modelling of the waste heat availability from gas turbine based CHP systems for ORC systems

PDF Search Title:

Assessment and modelling of the waste heat availability from gas turbine based CHP systems for ORC systemsOriginal File Name Searched:

714_firdaus.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |