PDF Publication Title:

Text from PDF Page: 038

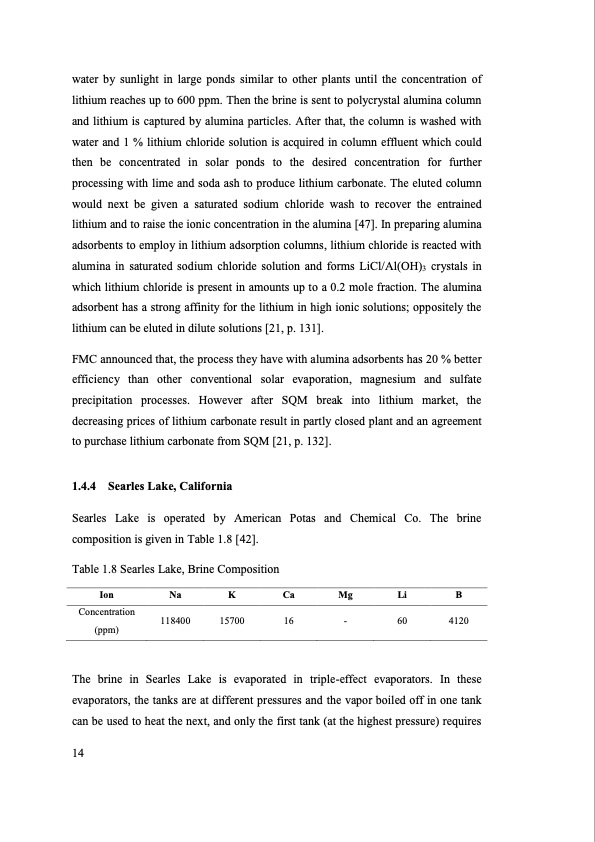

water by sunlight in large ponds similar to other plants until the concentration of lithium reaches up to 600 ppm. Then the brine is sent to polycrystal alumina column and lithium is captured by alumina particles. After that, the column is washed with water and 1 % lithium chloride solution is acquired in column effluent which could then be concentrated in solar ponds to the desired concentration for further processing with lime and soda ash to produce lithium carbonate. The eluted column would next be given a saturated sodium chloride wash to recover the entrained lithium and to raise the ionic concentration in the alumina [47]. In preparing alumina adsorbents to employ in lithium adsorption columns, lithium chloride is reacted with alumina in saturated sodium chloride solution and forms LiCl/Al(OH)3 crystals in which lithium chloride is present in amounts up to a 0.2 mole fraction. The alumina adsorbent has a strong affinity for the lithium in high ionic solutions; oppositely the lithium can be eluted in dilute solutions [21, p. 131]. FMC announced that, the process they have with alumina adsorbents has 20 % better efficiency than other conventional solar evaporation, magnesium and sulfate precipitation processes. However after SQM break into lithium market, the decreasing prices of lithium carbonate result in partly closed plant and an agreement to purchase lithium carbonate from SQM [21, p. 132]. 1.4.4 Searles Lake, California Searles Lake is operated by American Potas and Chemical Co. The brine composition is given in Table 1.8 [42]. Table 1.8 Searles Lake, Brine Composition Ion Na K Ca Mg Li B Concentration (ppm) 118400 15700 16 - 60 4120 The brine in Searles Lake is evaporated in triple-effect evaporators. In these evaporators, the tanks are at different pressures and the vapor boiled off in one tank can be used to heat the next, and only the first tank (at the highest pressure) requires 14PDF Image | SEPARATION OF LITHIUM FROM BRINES

PDF Search Title:

SEPARATION OF LITHIUM FROM BRINESOriginal File Name Searched:

separation-lithium-from-brine.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |