PDF Publication Title:

Text from PDF Page: 037

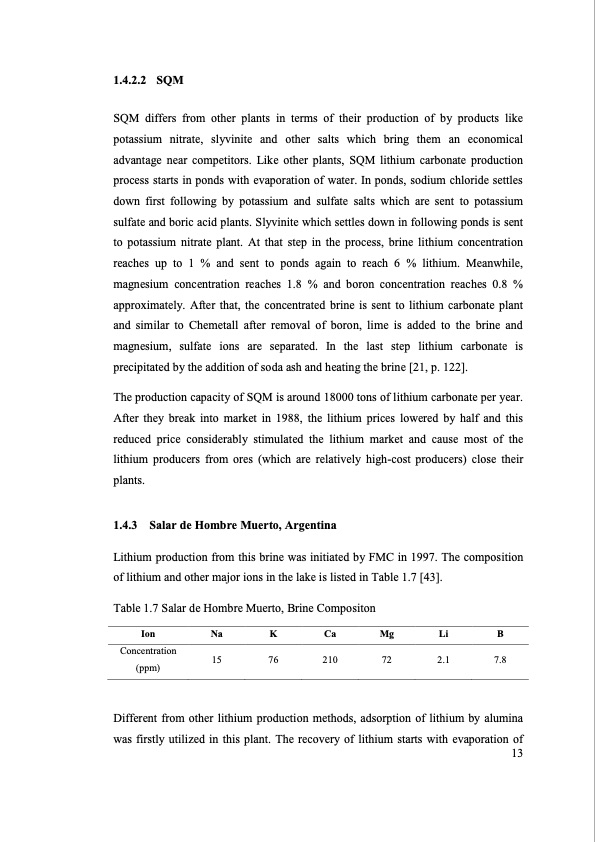

1.4.2.2 SQM SQM differs from other plants in terms of their production of by products like potassium nitrate, slyvinite and other salts which bring them an economical advantage near competitors. Like other plants, SQM lithium carbonate production process starts in ponds with evaporation of water. In ponds, sodium chloride settles down first following by potassium and sulfate salts which are sent to potassium sulfate and boric acid plants. Slyvinite which settles down in following ponds is sent to potassium nitrate plant. At that step in the process, brine lithium concentration reaches up to 1 % and sent to ponds again to reach 6 % lithium. Meanwhile, magnesium concentration reaches 1.8 % and boron concentration reaches 0.8 % approximately. After that, the concentrated brine is sent to lithium carbonate plant and similar to Chemetall after removal of boron, lime is added to the brine and magnesium, sulfate ions are separated. In the last step lithium carbonate is precipitated by the addition of soda ash and heating the brine [21, p. 122]. The production capacity of SQM is around 18000 tons of lithium carbonate per year. After they break into market in 1988, the lithium prices lowered by half and this reduced price considerably stimulated the lithium market and cause most of the lithium producers from ores (which are relatively high-cost producers) close their plants. 1.4.3 Salar de Hombre Muerto, Argentina Lithium production from this brine was initiated by FMC in 1997. The composition of lithium and other major ions in the lake is listed in Table 1.7 [43]. Table 1.7 Salar de Hombre Muerto, Brine Compositon Ion Na K Ca Mg Li B Concentration (ppm) 15 76 210 72 2.1 7.8 Different from other lithium production methods, adsorption of lithium by alumina was firstly utilized in this plant. The recovery of lithium starts with evaporation of 13PDF Image | SEPARATION OF LITHIUM FROM BRINES

PDF Search Title:

SEPARATION OF LITHIUM FROM BRINESOriginal File Name Searched:

separation-lithium-from-brine.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |