PDF Publication Title:

Text from PDF Page: 037

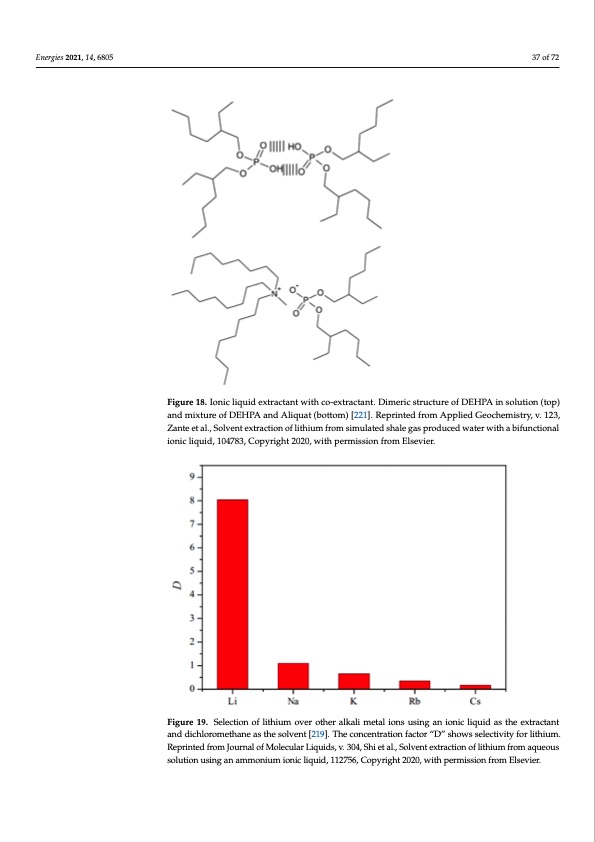

Energies 2021, 14, 6805 Figure 17. Chemical structures of ionic liquids [219]. Reprinted from Journal of Molecular Liqu37idosf,72 v. 304, Shi et al., Solvent extraction of lithium from aqueous solution using an ammonium ionic liquid, 112756, Copyright 2020, with permission from Elsevier. Energies 2021, 14, x FOR PEER REVIEW 39 of 74 Fiigurre18..IIoonniciclilqiquuidideexxtrtaracctatannttwwitihthcoc-oe-xetxrtarcatcatnatn.tD. DimimereicrisctrsutrcutuctrueroefoDfEDHEPHAPAinisnosluotliuotnio(nto(pto)p) and mixture of DEHPA and Aliquat (bottom) [221]. Reprinted from Applied Geochemistry, v. 123, and mixture of DEHPA and Aliquat (bottom) [221]. Reprinted from Applied Geochemistry, v. 123, Zante et al., Solvent extraction of lithium from simulated shale gas produced water with a bifunctional Zante et al., Solvent extraction of lithium from simulated shale gas produced water with a ionic liquid, 104783, Copyright 2020, with permission from Elsevier. bifunctional ionic liquid, 104783, Copyright 2020, with permission from Elsevier. Figure 19. Selection of lithium over other alkali metal ions using an ionic liquid as the extractant Figure 19. Selection of lithium over other alkali metal ions using an ionic liquid as the extractant and dichloromethane as the solvent [219]. The concentration factor “D” shows selectivity for and dichloromethane as the solvent [219]. The concentration factor “D” shows selectivity for lithium. lithium. Reprinted from Journal of Molecular Liquids, v. 304, Shi et al., Solvent extraction of lithium Reprinted from Journal of Molecular Liquids, v. 304, Shi et al., Solvent extraction of lithium from aqueous from aqueous solution using an ammonium ionic liquid, 112756, Copyright 2020, with permission solution using an ammonium ionic liquid, 112756, Copyright 2020, with permission from Elsevier. from Elsevier. Zhou et al. [183] used the ionic liquid diethyl succinate to extract lithium from simulated salt lake brines with high Mg/Li ratios. In this study, diethyl succinate was used as a diluent, TBP acted as the extractant, and FeCl3 was the co-extractant. The highest one- stage extraction efficiency of lithium was approximately 65%, with a maximum separation factor of 350. HCl + MgCl2 and HCl + NaCl were used as washing and stripping agents,PDF Image | Recovery of Lithium from Geothermal Brines

PDF Search Title:

Recovery of Lithium from Geothermal BrinesOriginal File Name Searched:

energies-14-06805-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |