PDF Publication Title:

Text from PDF Page: 002

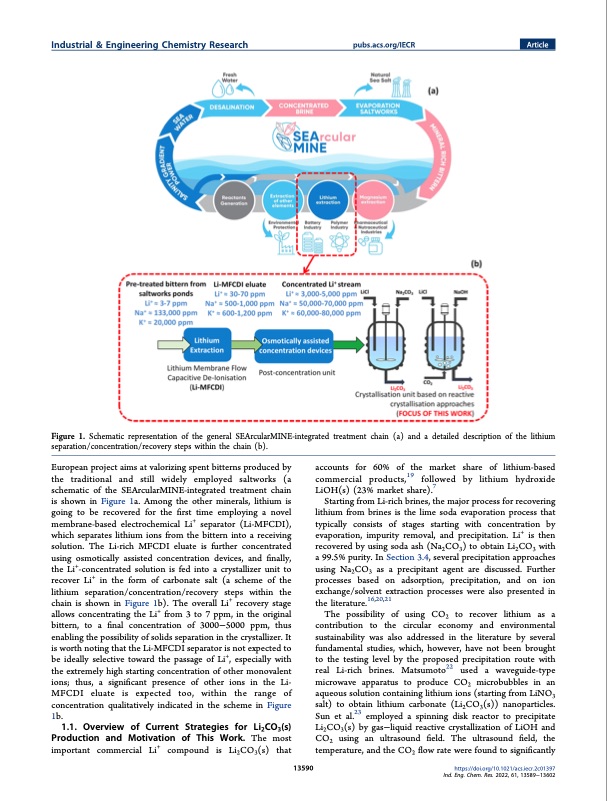

Industrial & Engineering Chemistry Research pubs.acs.org/IECR Article Figure 1. Schematic representation of the general SEArcularMINE-integrated treatment chain (a) and a detailed description of the lithium separation/concentration/recovery steps within the chain (b). European project aims at valorizing spent bitterns produced by the traditional and still widely employed saltworks (a schematic of the SEArcularMINE-integrated treatment chain is shown in Figure 1a. Among the other minerals, lithium is going to be recovered for the first time employing a novel membrane-based electrochemical Li+ separator (Li-MFCDI), which separates lithium ions from the bittern into a receiving solution. The Li-rich MFCDI eluate is further concentrated using osmotically assisted concentration devices, and finally, the Li+-concentrated solution is fed into a crystallizer unit to recover Li+ in the form of carbonate salt (a scheme of the lithium separation/concentration/recovery steps within the chain is shown in Figure 1b). The overall Li+ recovery stage allows concentrating the Li+ from 3 to 7 ppm, in the original bittern, to a final concentration of 3000−5000 ppm, thus enabling the possibility of solids separation in the crystallizer. It is worth noting that the Li-MFCDI separator is not expected to be ideally selective toward the passage of Li+, especially with the extremely high starting concentration of other monovalent ions; thus, a significant presence of other ions in the Li- MFCDI eluate is expected too, within the range of concentration qualitatively indicated in the scheme in Figure 1b. 1.1. Overview of Current Strategies for Li2CO3(s) Production and Motivation of This Work. The most important commercial Li+ compound is Li2CO3(s) that accounts for 60% of the market share of lithium-based commercial products,19 followed by lithium hydroxide LiOH(s) (23% market share).7 Starting from Li-rich brines, the major process for recovering lithium from brines is the lime soda evaporation process that typically consists of stages starting with concentration by evaporation, impurity removal, and precipitation. Li+ is then recovered by using soda ash (Na2CO3) to obtain Li2CO3 with a 99.5% purity. In Section 3.4, several precipitation approaches using Na2CO3 as a precipitant agent are discussed. Further processes based on adsorption, precipitation, and on ion exchange/solvent extraction processes were also presented in the literature.16,20,21 The possibility of using CO2 to recover lithium as a contribution to the circular economy and environmental sustainability was also addressed in the literature by several fundamental studies, which, however, have not been brought to the testing level by the proposed precipitation route with real Li-rich brines. Matsumoto22 used a waveguide-type microwave apparatus to produce CO2 microbubbles in an aqueous solution containing lithium ions (starting from LiNO3 salt) to obtain lithium carbonate (Li2CO3(s)) nanoparticles. Sun et al.23 employed a spinning disk reactor to precipitate Li2CO3(s) by gas−liquid reactive crystallization of LiOH and CO2 using an ultrasound field. The ultrasound field, the temperature, and the CO2 flow rate were found to significantly https://doi.org/10.1021/acs.iecr.2c01397 13590 Ind. Eng. Chem. Res. 2022, 61, 13589−13602PDF Image | Recovery of Lithium Carbonate from Dilute Li Rich Brine

PDF Search Title:

Recovery of Lithium Carbonate from Dilute Li Rich BrineOriginal File Name Searched:

acs.iecr.2c01397.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |