PDF Publication Title:

Text from PDF Page: 001

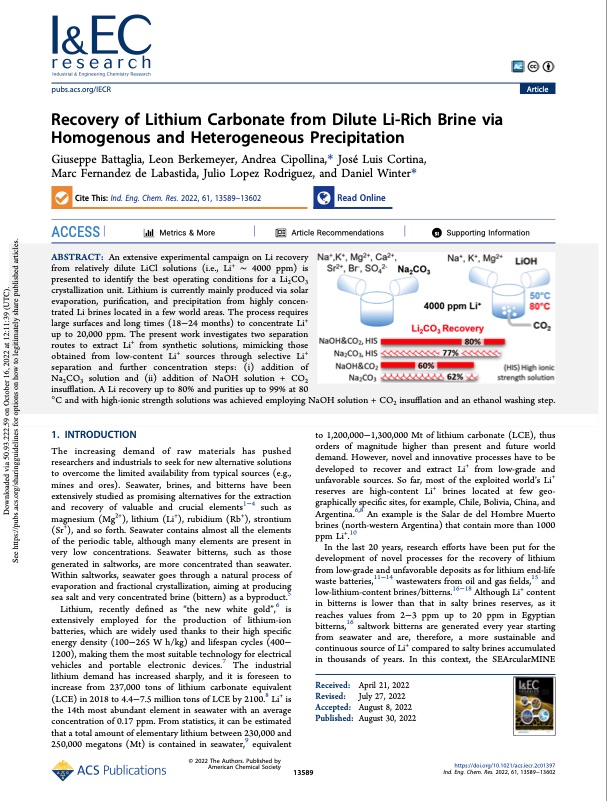

pubs.acs.org/IECR Recovery of Lithium Carbonate from Dilute Li-Rich Brine via Homogenous and Heterogeneous Precipitation Giuseppe Battaglia, Leon Berkemeyer, Andrea Cipollina,* José Luis Cortina, Marc Fernandez de Labastida, Julio Lopez Rodriguez, and Daniel Winter* Cite This: Ind. Eng. Chem. Res. 2022, 61, 13589−13602 ACCESS Metrics & More Read Online Article Recommendations *sı Supporting Information Article ABSTRACT: An extensive experimental campaign on Li recovery from relatively dilute LiCl solutions (i.e., Li+ ∼ 4000 ppm) is presented to identify the best operating conditions for a Li2CO3 crystallization unit. Lithium is currently mainly produced via solar evaporation, purification, and precipitation from highly concen- trated Li brines located in a few world areas. The process requires large surfaces and long times (18−24 months) to concentrate Li+ up to 20,000 ppm. The present work investigates two separation routes to extract Li+ from synthetic solutions, mimicking those obtained from low-content Li+ sources through selective Li+ separation and further concentration steps: (i) addition of Na2CO3 solution and (ii) addition of NaOH solution + CO2 insufflation. A Li recovery up to 80% and purities up to 99% at 80 °C and with high-ionic strength solutions was achieved employing NaOH solution + CO2 insufflation and an ethanol washing step. 1. INTRODUCTION The increasing demand of raw materials has pushed researchers and industrials to seek for new alternative solutions to overcome the limited availability from typical sources (e.g., mines and ores). Seawater, brines, and bitterns have been extensively studied as promising alternatives for the extraction and recovery of valuable and crucial elements1−4 such as magnesium (Mg2+), lithium (Li+), rubidium (Rb+), strontium (Sr+), and so forth. Seawater contains almost all the elements of the periodic table, although many elements are present in very low concentrations. Seawater bitterns, such as those generated in saltworks, are more concentrated than seawater. Within saltworks, seawater goes through a natural process of evaporation and fractional crystallization, aiming at producing sea salt and very concentrated brine (bittern) as a byproduct.5 Lithium, recently defined as “the new white gold”,6 is extensively employed for the production of lithium-ion batteries, which are widely used thanks to their high specific energy density (100−265 W h/kg) and lifespan cycles (400− 1200), making them the most suitable technology for electrical vehicles and portable electronic devices.7 The industrial lithium demand has increased sharply, and it is foreseen to increase from 237,000 tons of lithium carbonate equivalent (LCE) in 2018 to 4.4−7.5 million tons of LCE by 2100.8 Li+ is the 14th most abundant element in seawater with an average concentration of 0.17 ppm. From statistics, it can be estimated that a total amount of elementary lithium between 230,000 and 250,000 megatons (Mt) is contained in seawater,9 equivalent © 2022 The Authors. Published by American Chemical Society to 1,200,000−1,300,000 Mt of lithium carbonate (LCE), thus orders of magnitude higher than present and future world demand. However, novel and innovative processes have to be developed to recover and extract Li+ from low-grade and unfavorable sources. So far, most of the exploited world’s Li+ reserves are high-content Li+ brines located at few geo- graphically specific sites, for example, Chile, Bolivia, China, and Argentina.6,8 An example is the Salar de del Hombre Muerto brines (north-western Argentina) that contain more than 1000 ppm Li+.10 In the last 20 years, research efforts have been put for the development of novel processes for the recovery of lithium from low-grade and unfavorable deposits as for lithium end-life waste batteries,11−14 wastewaters from oil and gas fields,15 and low-lithium-content brines/bitterns.16−18 Although Li+ content in bitterns is lower than that in salty brines reserves, as it reaches values from 2−3 ppm up to 20 ppm in Egyptian bitterns,16 saltwork bitterns are generated every year starting from seawater and are, therefore, a more sustainable and continuous source of Li+ compared to salty brines accumulated in thousands of years. In this context, the SEArcularMINE https://doi.org/10.1021/acs.iecr.2c01397 Ind. Eng. Chem. Res. 2022, 61, 13589−13602 13589 Received: Revised: Accepted: Published: August 30, 2022 April 21, 2022 July 27, 2022 August 8, 2022 Downloaded via 50.93.222.59 on October 16, 2022 at 12:11:39 (UTC). See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles.PDF Image | Recovery of Lithium Carbonate from Dilute Li Rich Brine

PDF Search Title:

Recovery of Lithium Carbonate from Dilute Li Rich BrineOriginal File Name Searched:

acs.iecr.2c01397.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |