PDF Publication Title:

Text from PDF Page: 013

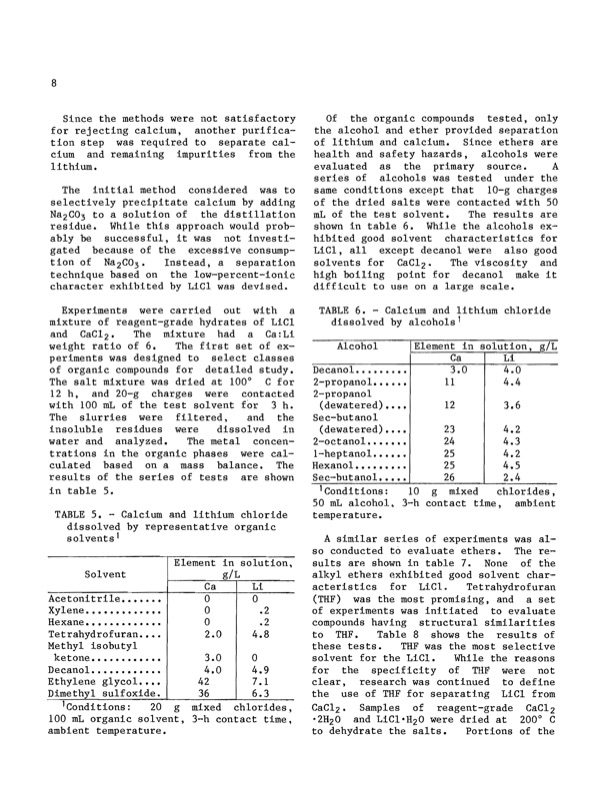

8 Since the methods were not satisfactory for rejecting calcium, another purifica- tion step was required to separate cal- cium and remaining impurities from the lithium. The initial method considered was to selectively precipitate calcium by adding Na2C03 to a solution of the distillation residue. While this approach would prob- ably be successful, it was not investi- gated because of the excessive consump- tion of Na2C03' Instead, a separation technique based on the low-percent-ionic character exhibited by LiCI was devised. Experiments were carried out with a mixture of reagent-grade hydrates of LiCI and CaCI2• The mixture had a Ca:Li weight ratio of 6. The first set of ex- periments was designed to select classes of organic compounds for detailed study. The salt mixture was dried at 1000 C for 12 h, and 20-g charges were contacted with 100 mL of the test solvent for 3 h. The slurries were filtered, and the insoluble residues were dissolved in water and analyzed. The metal concen- trations in the organic phases were cal- culated based on a mass balance. The results of the series of tests are shown in table 5. TABLE 5. - Calcium and lithium chloride dissolved by representative organic solvents 1 Of the organic compounds tested, only the alcohol and ether provided separation of lithium and calcium. Since ethers are health and safety hazards, alcohols were evaluated as the primary source. A series of alcohols was tested under the same conditions except that 10-g charges of the dried salts were contacted with 50 mL of the test solvent. The results are shown in table 6. While the alcohols ex- hibited good solvent characteristics for LiCI, all except decanol were also good solvents for CaCI2• The viscosity and high boiling point for decanol make it difficult to use on a large scale. TABLE 6. - Calcium and lithium chloride dissolved by alcohols1 Solvent A cetonitrile ••••••• Xylene............. . Hexane ••••••••••••• Tetrahydrofuran•••• Methyl isobutyl ketone............ Decanol............ Ethylene glycol.... Dimethyl sulfoxide. Element in solution, giL 1Conditions: 20 100 mL organic solvent, 3-h contact time, ambient temperature. g Ca oo o .2 o .2 2.0 4.8 3.0 0 4.0 4.9 42 7.1 36 6.3 mixed chlorides, L1 Element in solution, giL Ca Li 3.0 4.0 11 4.4 12 3.6 23 4.2 24 4.3 25 4.2 25 4.5 26 2.4 A similar series of experiments was al- so conducted to evaluate ethers. The re- sults are shown in table 7. None of the alkyl ethers exhibited good solvent char- acteristics for LiCl. Tetrahydrofuran (THF) was the most promising, and a set of experiments was initiated to evaluate compounds having structural similarities to THF. Table 8 shows the results of these tests. THF was the most selective solvent for the LiCl. While the reasons for the specificity of THF were not clear, research was continued to define the use of THF for separating LiCI from CaCI2' Samples of reagent-grade CaCl2 '2H20 and LiCI'H20 were dried at 2000 C to dehydrate the salts. Portions of the Alcohol Decanol ••••••••• 2-propanol•••••• 2-propanol (dewatered) •••• Sec-butanol (dewatered) •••• 2-octanol••••••• 1-heptanol.••••• Hexanol ••••••••• Sec-butanol••••• 1Conditions: 50 mL alcohol. 3-h contact time, ambient temperature. 10 g mixed chlorides,PDF Image | Recovering Lithium Chloride From a Geothermal Brine 1984

PDF Search Title:

Recovering Lithium Chloride From a Geothermal Brine 1984Original File Name Searched:

cdc_10654_DS1.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |