PDF Publication Title:

Text from PDF Page: 013

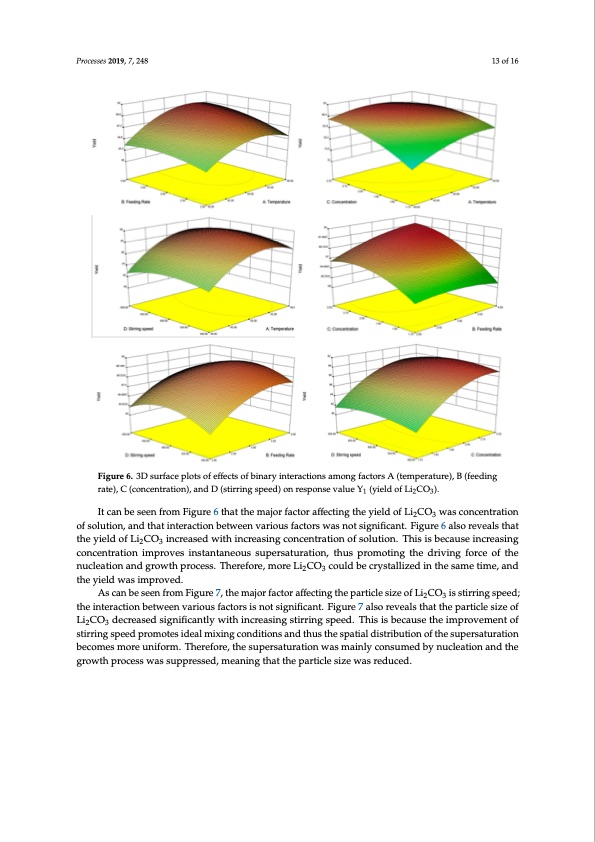

Processes 2019, 7, 248 13 of 16 Processes 2018, 6, x FOR PEER REVIEW 14 of 17 Figure 6. 3D surface plots of effects of binary interactions among factors A (temperature), B (feeding rate), C (concentration), and D (stirring speed) on response value Y1 (yield of Li2CO3). Figure 6. 3D surface plots of effects of binary interactions among factors A (temperature), B (feeding rate), C (concentration), and D (stirring speed) on response value Y1 (yield of Li2CO3). It can be seen from Figure 6 that the major factor affecting the yield of Li2CO3 was concentration of solution, and that interaction between various factors was not significant. Figure 6 also reveals that As can be seen from Figure 7, the major factor affecting the particle size of Li2CO3 is stirring the yield of Li CO increased with increasing concentration of solution. This is because increasing speed; the in2terac3tion between various factors is not significant. Figure 7 also reveals that the particle concentration improves instantaneous supersaturation, thus promoting the driving force of the size of Li2CO3 decreased significantly with increasing stirring speed. This is because the improvement nucleationandgrowthprocess.Therefore,moreLiCO couldbecrystallizedinthesametime,and of stirring speed promotes ideal mixing conditi2ons3and thus the spatial distribution of the thesuypielrdsawtuarsatiimonprboevceodm.es more uniform. Therefore, the supersaturation was mainly consumed by nuAclesactaionnbaensdeetnhefrgormowFtihgupreoc7e,stshwe masasjourpfparcetsosredaff, mecetiangintghethpaatrthicelepsairztiecloefsLizi eCwOasirsesdtuircreindg. speed; 23 the interaction between various factors is not significant. Figure 7 also reveals that the particle size of Li2CO3 decreased significantly with increasing stirring speed. This is because the improvement of stirring speed promotes ideal mixing conditions and thus the spatial distribution of the supersaturation becomes more uniform. Therefore, the supersaturation was mainly consumed by nucleation and the growth process was suppressed, meaning that the particle size was reduced.PDF Image | Reactive Crystallization Process of Lithium Carbonate

PDF Search Title:

Reactive Crystallization Process of Lithium CarbonateOriginal File Name Searched:

processes-07-00248-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |