PDF Publication Title:

Text from PDF Page: 027

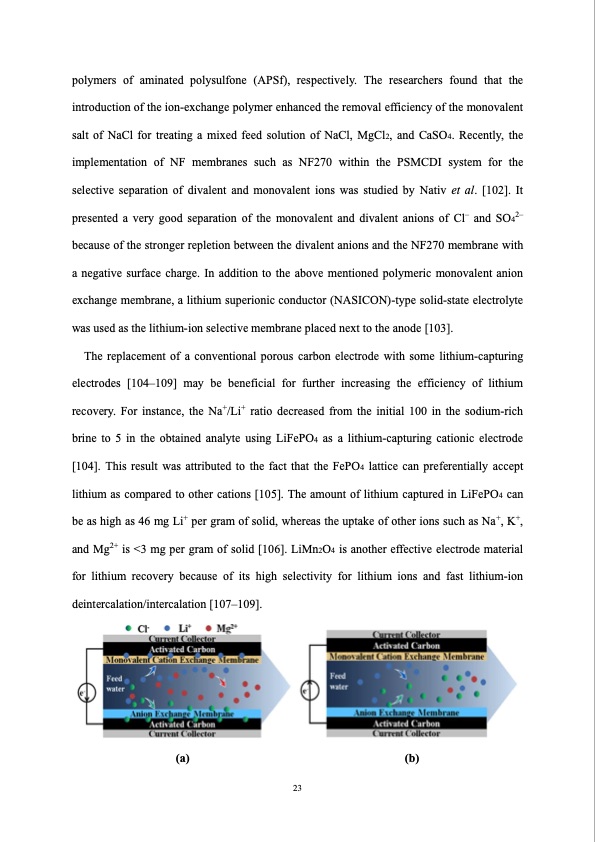

polymers of aminated polysulfone (APSf), respectively. The researchers found that the introduction of the ion-exchange polymer enhanced the removal efficiency of the monovalent salt of NaCl for treating a mixed feed solution of NaCl, MgCl2, and CaSO4. Recently, the implementation of NF membranes such as NF270 within the PSMCDI system for the selective separation of divalent and monovalent ions was studied by Nativ et al. [102]. It presented a very good separation of the monovalent and divalent anions of Cl– and SO42– because of the stronger repletion between the divalent anions and the NF270 membrane with a negative surface charge. In addition to the above mentioned polymeric monovalent anion exchange membrane, a lithium superionic conductor (NASICON)-type solid-state electrolyte was used as the lithium-ion selective membrane placed next to the anode [103]. The replacement of a conventional porous carbon electrode with some lithium-capturing electrodes [104–109] may be beneficial for further increasing the efficiency of lithium recovery. For instance, the Na+/Li+ ratio decreased from the initial 100 in the sodium-rich brine to 5 in the obtained analyte using LiFePO4 as a lithium-capturing cationic electrode [104]. This result was attributed to the fact that the FePO4 lattice can preferentially accept lithium as compared to other cations [105]. The amount of lithium captured in LiFePO4 can be as high as 46 mg Li+ per gram of solid, whereas the uptake of other ions such as Na+, K+, and Mg2+ is <3 mg per gram of solid [106]. LiMn2O4 is another effective electrode material for lithium recovery because of its high selectivity for lithium ions and fast lithium-ion deintercalation/intercalation [107–109]. (a) (b) 23PDF Image | Membrane based technologies for lithium recovery from water lithium

PDF Search Title:

Membrane based technologies for lithium recovery from water lithiumOriginal File Name Searched:

Content.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |