PDF Publication Title:

Text from PDF Page: 026

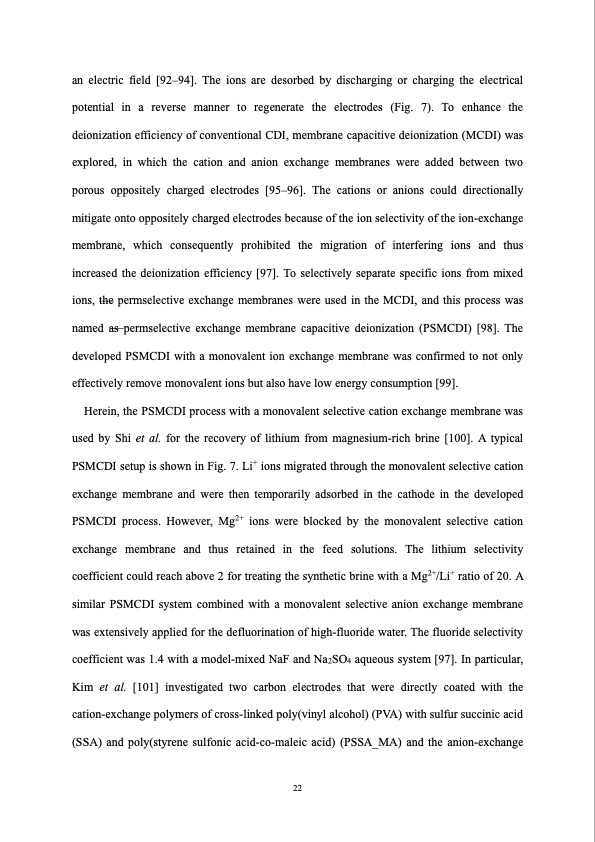

an electric field [92–94]. The ions are desorbed by discharging or charging the electrical potential in a reverse manner to regenerate the electrodes (Fig. 7). To enhance the deionization efficiency of conventional CDI, membrane capacitive deionization (MCDI) was explored, in which the cation and anion exchange membranes were added between two porous oppositely charged electrodes [95–96]. The cations or anions could directionally mitigate onto oppositely charged electrodes because of the ion selectivity of the ion-exchange membrane, which consequently prohibited the migration of interfering ions and thus increased the deionization efficiency [97]. To selectively separate specific ions from mixed ions, the permselective exchange membranes were used in the MCDI, and this process was named as permselective exchange membrane capacitive deionization (PSMCDI) [98]. The developed PSMCDI with a monovalent ion exchange membrane was confirmed to not only effectively remove monovalent ions but also have low energy consumption [99]. Herein, the PSMCDI process with a monovalent selective cation exchange membrane was used by Shi et al. for the recovery of lithium from magnesium-rich brine [100]. A typical PSMCDI setup is shown in Fig. 7. Li+ ions migrated through the monovalent selective cation exchange membrane and were then temporarily adsorbed in the cathode in the developed PSMCDI process. However, Mg2+ ions were blocked by the monovalent selective cation exchange membrane and thus retained in the feed solutions. The lithium selectivity coefficient could reach above 2 for treating the synthetic brine with a Mg2+/Li+ ratio of 20. A similar PSMCDI system combined with a monovalent selective anion exchange membrane was extensively applied for the defluorination of high-fluoride water. The fluoride selectivity coefficient was 1.4 with a model-mixed NaF and Na2SO4 aqueous system [97]. In particular, Kim et al. [101] investigated two carbon electrodes that were directly coated with the cation-exchange polymers of cross-linked poly(vinyl alcohol) (PVA) with sulfur succinic acid (SSA) and poly(styrene sulfonic acid-co-maleic acid) (PSSA_MA) and the anion-exchange 22PDF Image | Membrane based technologies for lithium recovery from water lithium

PDF Search Title:

Membrane based technologies for lithium recovery from water lithiumOriginal File Name Searched:

Content.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |