PDF Publication Title:

Text from PDF Page: 067

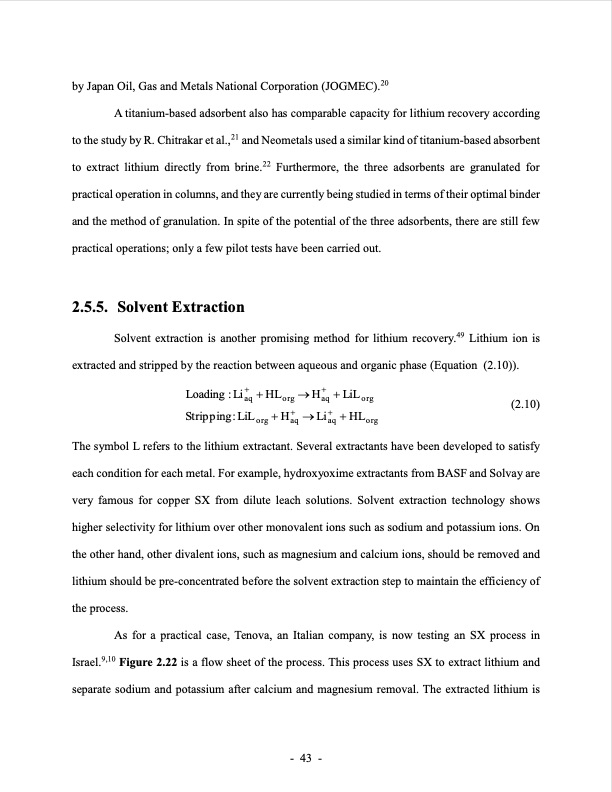

by Japan Oil, Gas and Metals National Corporation (JOGMEC).20 A titanium-based adsorbent also has comparable capacity for lithium recovery according to the study by R. Chitrakar et al.,21 and Neometals used a similar kind of titanium-based absorbent to extract lithium directly from brine.22 Furthermore, the three adsorbents are granulated for practical operation in columns, and they are currently being studied in terms of their optimal binder and the method of granulation. In spite of the potential of the three adsorbents, there are still few practical operations; only a few pilot tests have been carried out. 2.5.5. SolventExtraction Solvent extraction is another promising method for lithium recovery.49 Lithium ion is extracted and stripped by the reaction between aqueous and organic phase (Equation (2.10)). (2.10) The symbol L refers to the lithium extractant. Several extractants have been developed to satisfy each condition for each metal. For example, hydroxyoxime extractants from BASF and Solvay are very famous for copper SX from dilute leach solutions. Solvent extraction technology shows higher selectivity for lithium over other monovalent ions such as sodium and potassium ions. On the other hand, other divalent ions, such as magnesium and calcium ions, should be removed and lithium should be pre-concentrated before the solvent extraction step to maintain the efficiency of the process. As for a practical case, Tenova, an Italian company, is now testing an SX process in Israel.9,10 Figure 2.22 is a flow sheet of the process. This process uses SX to extract lithium and separate sodium and potassium after calcium and magnesium removal. The extracted lithium is Loading:Li+ +HL →H+ +LiL aq org aq Stripping:LiL +H+ →Li+ +HL org aq aq - 43 - org orgPDF Image | LITHIUM EXTRACTION FROM BRINE using ion resin

PDF Search Title:

LITHIUM EXTRACTION FROM BRINE using ion resinOriginal File Name Searched:

3.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |