PDF Publication Title:

Text from PDF Page: 002

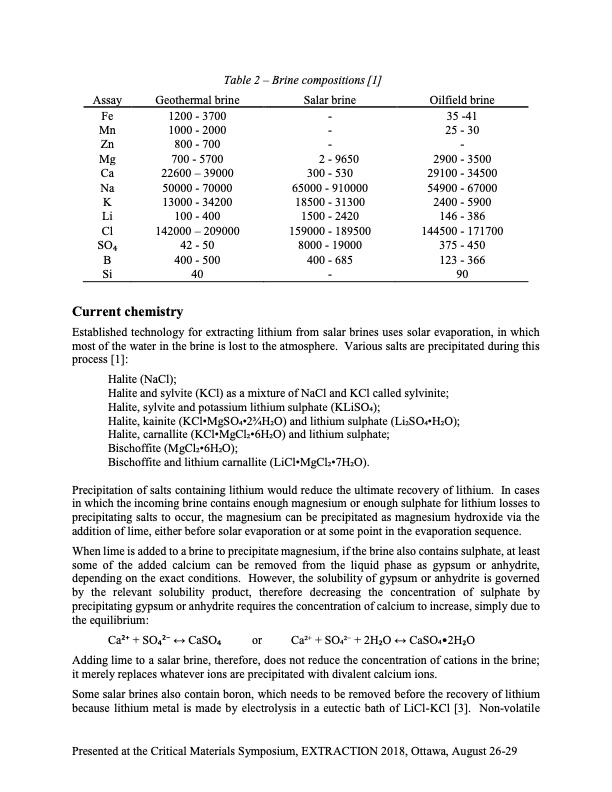

Assay Fe Mn Zn Mg Ca Na K Li Cl SO4 B Geothermal brine 1200 - 3700 1000 - 2000 800 - 700 700 - 5700 22600 – 39000 50000 - 70000 13000 - 34200 100 - 400 142000 – 209000 42 - 50 400 - 500 Salar brine - - - 2 - 9650 300 - 530 65000 - 910000 18500 - 31300 1500 - 2420 159000 - 189500 8000 - 19000 400 - 685 - Oilfield brine 35 -41 25 - 30 - 2900 - 3500 29100 - 34500 54900 - 67000 2400 - 5900 146 - 386 144500 - 171700 375 - 450 123 - 366 90 Si 40 Current chemistry Table 2 – Brine compositions [1] Established technology for extracting lithium from salar brines uses solar evaporation, in which most of the water in the brine is lost to the atmosphere. Various salts are precipitated during this process [1]: Halite (NaCl); Halite and sylvite (KCl) as a mixture of NaCl and KCl called sylvinite; Halite, sylvite and potassium lithium sulphate (KLiSO4); Halite, kainite (KCl•MgSO4•23⁄4H2O) and lithium sulphate (Li2SO4•H2O); Halite, carnallite (KCl•MgCl2•6H2O) and lithium sulphate; Bischoffite (MgCl2•6H2O); Bischoffite and lithium carnallite (LiCl•MgCl2•7H2O). Precipitation of salts containing lithium would reduce the ultimate recovery of lithium. In cases in which the incoming brine contains enough magnesium or enough sulphate for lithium losses to precipitating salts to occur, the magnesium can be precipitated as magnesium hydroxide via the addition of lime, either before solar evaporation or at some point in the evaporation sequence. When lime is added to a brine to precipitate magnesium, if the brine also contains sulphate, at least some of the added calcium can be removed from the liquid phase as gypsum or anhydrite, depending on the exact conditions. However, the solubility of gypsum or anhydrite is governed by the relevant solubility product, therefore decreasing the concentration of sulphate by precipitating gypsum or anhydrite requires the concentration of calcium to increase, simply due to the equilibrium: Ca2+ + SO42− ↔ CaSO4 or Ca2+ + SO42− + 2H2O ↔ CaSO4•2H2O Adding lime to a salar brine, therefore, does not reduce the concentration of cations in the brine; it merely replaces whatever ions are precipitated with divalent calcium ions. Some salar brines also contain boron, which needs to be removed before the recovery of lithium because lithium metal is made by electrolysis in a eutectic bath of LiCl-KCl [3]. Non-volatile Presented at the Critical Materials Symposium, EXTRACTION 2018, Ottawa, August 26-29PDF Image | Extraction of Lithium from Brine Chemistry

PDF Search Title:

Extraction of Lithium from Brine ChemistryOriginal File Name Searched:

Extraction of Lithium from Brine 13 Old and New Chemistry.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |