PDF Publication Title:

Text from PDF Page: 001

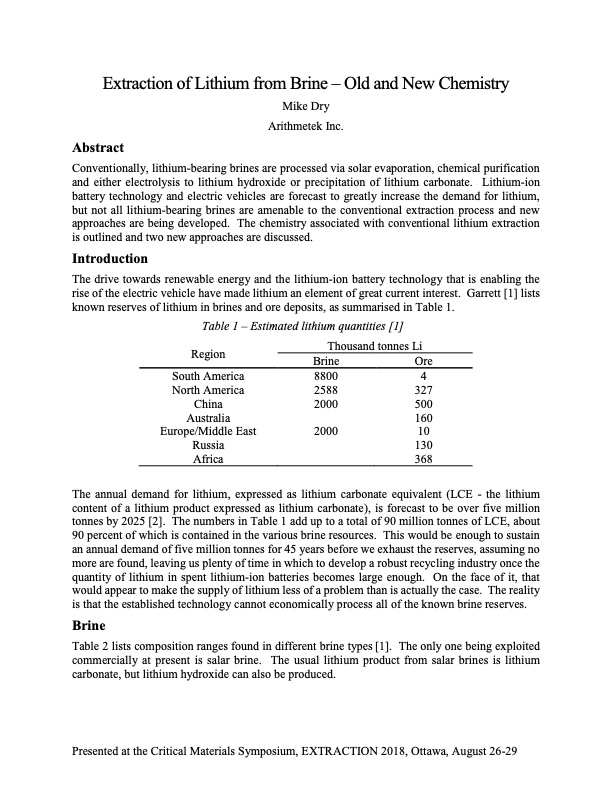

Extraction of Lithium from Brine – Old and New Chemistry Mike Dry Arithmetek Inc. Abstract Conventionally, lithium-bearing brines are processed via solar evaporation, chemical purification and either electrolysis to lithium hydroxide or precipitation of lithium carbonate. Lithium-ion battery technology and electric vehicles are forecast to greatly increase the demand for lithium, but not all lithium-bearing brines are amenable to the conventional extraction process and new approaches are being developed. The chemistry associated with conventional lithium extraction is outlined and two new approaches are discussed. Introduction The drive towards renewable energy and the lithium-ion battery technology that is enabling the rise of the electric vehicle have made lithium an element of great current interest. Garrett [1] lists known reserves of lithium in brines and ore deposits, as summarised in Table 1. Table 1 – Estimated lithium quantities [1] Region South America North America China Australia Europe/Middle East Russia Africa Thousand tonnes Li Brine Ore 8800 4 2588 327 2000 500 160 2000 10 130 368 The annual demand for lithium, expressed as lithium carbonate equivalent (LCE - the lithium content of a lithium product expressed as lithium carbonate), is forecast to be over five million tonnes by 2025 [2]. The numbers in Table 1 add up to a total of 90 million tonnes of LCE, about 90 percent of which is contained in the various brine resources. This would be enough to sustain an annual demand of five million tonnes for 45 years before we exhaust the reserves, assuming no more are found, leaving us plenty of time in which to develop a robust recycling industry once the quantity of lithium in spent lithium-ion batteries becomes large enough. On the face of it, that would appear to make the supply of lithium less of a problem than is actually the case. The reality is that the established technology cannot economically process all of the known brine reserves. Brine Table 2 lists composition ranges found in different brine types [1]. The only one being exploited commercially at present is salar brine. The usual lithium product from salar brines is lithium carbonate, but lithium hydroxide can also be produced. Presented at the Critical Materials Symposium, EXTRACTION 2018, Ottawa, August 26-29PDF Image | Extraction of Lithium from Brine Chemistry

PDF Search Title:

Extraction of Lithium from Brine ChemistryOriginal File Name Searched:

Extraction of Lithium from Brine 13 Old and New Chemistry.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |