PDF Publication Title:

Text from PDF Page: 002

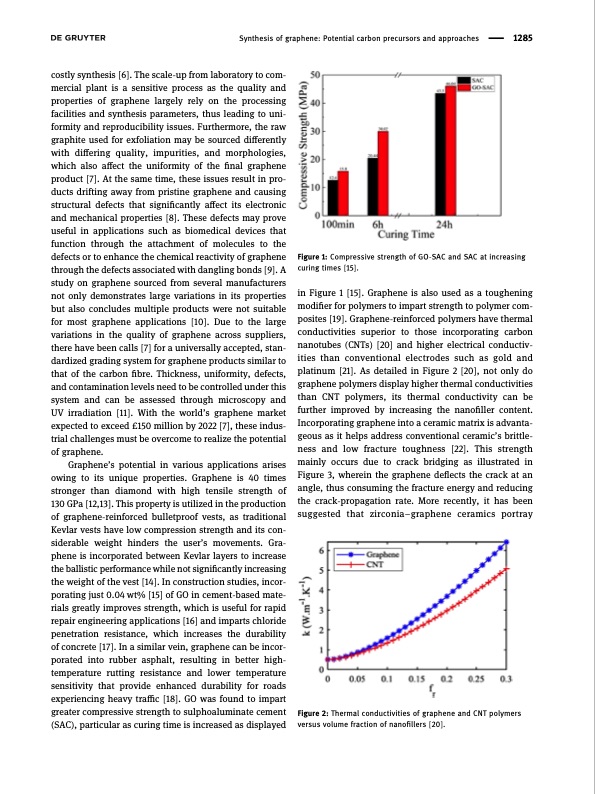

costly synthesis [6]. The scale-up from laboratory to com- mercial plant is a sensitive process as the quality and properties of graphene largely rely on the processing facilities and synthesis parameters, thus leading to uni- formity and reproducibility issues. Furthermore, the raw graphite used for exfoliation may be sourced differently with differing quality, impurities, and morphologies, which also affect the uniformity of the final graphene product [7]. At the same time, these issues result in pro- ducts drifting away from pristine graphene and causing structural defects that significantly affect its electronic and mechanical properties [8]. These defects may prove useful in applications such as biomedical devices that function through the attachment of molecules to the defects or to enhance the chemical reactivity of graphene through the defects associated with dangling bonds [9]. A study on graphene sourced from several manufacturers not only demonstrates large variations in its properties but also concludes multiple products were not suitable for most graphene applications [10]. Due to the large variations in the quality of graphene across suppliers, there have been calls [7] for a universally accepted, stan- dardized grading system for graphene products similar to that of the carbon fibre. Thickness, uniformity, defects, and contamination levels need to be controlled under this system and can be assessed through microscopy and UV irradiation [11]. With the world’s graphene market expected to exceed £150 million by 2022 [7], these indus- trial challenges must be overcome to realize the potential of graphene. Graphene’s potential in various applications arises owing to its unique properties. Graphene is 40 times stronger than diamond with high tensile strength of 130 GPa [12,13]. This property is utilized in the production of graphene-reinforced bulletproof vests, as traditional Kevlar vests have low compression strength and its con- siderable weight hinders the user’s movements. Gra- phene is incorporated between Kevlar layers to increase the ballistic performance while not significantly increasing the weight of the vest [14]. In construction studies, incor- porating just 0.04 wt% [15] of GO in cement-based mate- rials greatly improves strength, which is useful for rapid repair engineering applications [16] and imparts chloride penetration resistance, which increases the durability of concrete [17]. In a similar vein, graphene can be incor- porated into rubber asphalt, resulting in better high- temperature rutting resistance and lower temperature sensitivity that provide enhanced durability for roads experiencing heavy traffic [18]. GO was found to impart greater compressive strength to sulphoaluminate cement (SAC), particular as curing time is increased as displayed Figure 1: Compressive strength of GO-SAC and SAC at increasing curing times [15]. in Figure 1 [15]. Graphene is also used as a toughening modifier for polymers to impart strength to polymer com- posites [19]. Graphene-reinforced polymers have thermal conductivities superior to those incorporating carbon nanotubes (CNTs) [20] and higher electrical conductiv- ities than conventional electrodes such as gold and platinum [21]. As detailed in Figure 2 [20], not only do graphene polymers display higher thermal conductivities than CNT polymers, its thermal conductivity can be further improved by increasing the nanofiller content. Incorporating graphene into a ceramic matrix is advanta- geous as it helps address conventional ceramic’s brittle- ness and low fracture toughness [22]. This strength mainly occurs due to crack bridging as illustrated in Figure 3, wherein the graphene deflects the crack at an angle, thus consuming the fracture energy and reducing the crack-propagation rate. More recently, it has been suggested that zirconia–graphene ceramics portray Figure 2: Thermal conductivities of graphene and CNT polymers versus volume fraction of nanofillers [20]. Synthesis of graphene: Potential carbon precursors and approaches 1285PDF Image | Synthesis of graphene Potential carbon precursors

PDF Search Title:

Synthesis of graphene Potential carbon precursorsOriginal File Name Searched:

10-1515-ntrev-2020-0100.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |