PDF Publication Title:

Text from PDF Page: 003

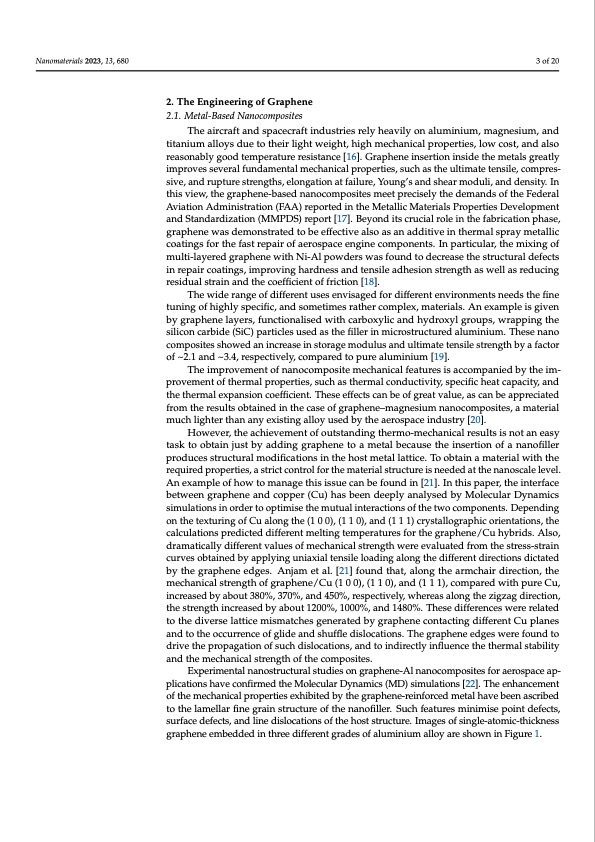

Nanomaterials 2023, 13, 680 3 of 20 2. The Engineering of Graphene 2.1. Metal-Based Nanocomposites The aircraft and spacecraft industries rely heavily on aluminium, magnesium, and titanium alloys due to their light weight, high mechanical properties, low cost, and also reasonably good temperature resistance [16]. Graphene insertion inside the metals greatly improves several fundamental mechanical properties, such as the ultimate tensile, compres- sive, and rupture strengths, elongation at failure, Young’s and shear moduli, and density. In this view, the graphene-based nanocomposites meet precisely the demands of the Federal Aviation Administration (FAA) reported in the Metallic Materials Properties Development and Standardization (MMPDS) report [17]. Beyond its crucial role in the fabrication phase, graphene was demonstrated to be effective also as an additive in thermal spray metallic coatings for the fast repair of aerospace engine components. In particular, the mixing of multi-layered graphene with Ni-Al powders was found to decrease the structural defects in repair coatings, improving hardness and tensile adhesion strength as well as reducing residual strain and the coefficient of friction [18]. The wide range of different uses envisaged for different environments needs the fine tuning of highly specific, and sometimes rather complex, materials. An example is given by graphene layers, functionalised with carboxylic and hydroxyl groups, wrapping the silicon carbide (SiC) particles used as the filler in microstructured aluminium. These nano composites showed an increase in storage modulus and ultimate tensile strength by a factor of ~2.1 and ~3.4, respectively, compared to pure aluminium [19]. The improvement of nanocomposite mechanical features is accompanied by the im- provement of thermal properties, such as thermal conductivity, specific heat capacity, and the thermal expansion coefficient. These effects can be of great value, as can be appreciated from the results obtained in the case of graphene–magnesium nanocomposites, a material much lighter than any existing alloy used by the aerospace industry [20]. However, the achievement of outstanding thermo-mechanical results is not an easy task to obtain just by adding graphene to a metal because the insertion of a nanofiller produces structural modifications in the host metal lattice. To obtain a material with the required properties, a strict control for the material structure is needed at the nanoscale level. An example of how to manage this issue can be found in [21]. In this paper, the interface between graphene and copper (Cu) has been deeply analysed by Molecular Dynamics simulations in order to optimise the mutual interactions of the two components. Depending on the texturing of Cu along the (1 0 0), (1 1 0), and (1 1 1) crystallographic orientations, the calculations predicted different melting temperatures for the graphene/Cu hybrids. Also, dramatically different values of mechanical strength were evaluated from the stress-strain curves obtained by applying uniaxial tensile loading along the different directions dictated by the graphene edges. Anjam et al. [21] found that, along the armchair direction, the mechanical strength of graphene/Cu (1 0 0), (1 1 0), and (1 1 1), compared with pure Cu, increased by about 380%, 370%, and 450%, respectively, whereas along the zigzag direction, the strength increased by about 1200%, 1000%, and 1480%. These differences were related to the diverse lattice mismatches generated by graphene contacting different Cu planes and to the occurrence of glide and shuffle dislocations. The graphene edges were found to drive the propagation of such dislocations, and to indirectly influence the thermal stability and the mechanical strength of the composites. Experimental nanostructural studies on graphene-Al nanocomposites for aerospace ap- plications have confirmed the Molecular Dynamics (MD) simulations [22]. The enhancement of the mechanical properties exhibited by the graphene-reinforced metal have been ascribed to the lamellar fine grain structure of the nanofiller. Such features minimise point defects, surface defects, and line dislocations of the host structure. Images of single-atomic-thickness graphene embedded in three different grades of aluminium alloy are shown in Figure 1.PDF Image | Role of Graphene in Space Technology

PDF Search Title:

Role of Graphene in Space TechnologyOriginal File Name Searched:

nanomaterials-13-00680-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |