PDF Publication Title:

Text from PDF Page: 003

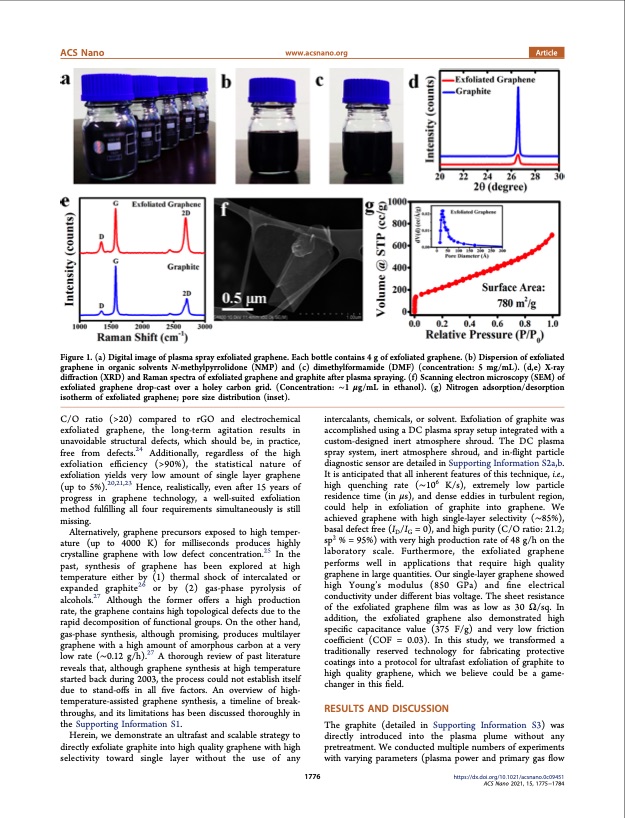

ACS Nano www.acsnano.org Article Figure 1. (a) Digital image of plasma spray exfoliated graphene. Each bottle contains 4 g of exfoliated graphene. (b) Dispersion of exfoliated graphene in organic solvents N-methylpyrrolidone (NMP) and (c) dimethylformamide (DMF) (concentration: 5 mg/mL). (d,e) X-ray diffraction (XRD) and Raman spectra of exfoliated graphene and graphite after plasma spraying. (f) Scanning electron microscopy (SEM) of exfoliated graphene drop-cast over a holey carbon grid. (Concentration: ∼1 μg/mL in ethanol). (g) Nitrogen adsorption/desorption isotherm of exfoliated graphene; pore size distribution (inset). C/O ratio (>20) compared to rGO and electrochemical exfoliated graphene, the long-term agitation results in unavoidable structural defects, which should be, in practice, free from defects.24 Additionally, regardless of the high exfoliation efficiency (>90%), the statistical nature of exfoliation yields very low amount of single layer graphene (up to 5%).20,21,23 Hence, realistically, even after 15 years of progress in graphene technology, a well-suited exfoliation method fulfilling all four requirements simultaneously is still missing. Alternatively, graphene precursors exposed to high temper- ature (up to 4000 K) for milliseconds produces highly crystalline graphene with low defect concentration.25 In the past, synthesis of graphene has been explored at high temperature either by (1) thermal shock of intercalated or expanded graphite26 or by (2) gas-phase pyrolysis of alcohols.27 Although the former offers a high production rate, the graphene contains high topological defects due to the rapid decomposition of functional groups. On the other hand, gas-phase synthesis, although promising, produces multilayer graphene with a high amount of amorphous carbon at a very low rate (∼0.12 g/h).27 A thorough review of past literature reveals that, although graphene synthesis at high temperature started back during 2003, the process could not establish itself due to stand-offs in all five factors. An overview of high- temperature-assisted graphene synthesis, a timeline of break- throughs, and its limitations has been discussed thoroughly in the Supporting Information S1. Herein, we demonstrate an ultrafast and scalable strategy to directly exfoliate graphite into high quality graphene with high selectivity toward single layer without the use of any intercalants, chemicals, or solvent. Exfoliation of graphite was accomplished using a DC plasma spray setup integrated with a custom-designed inert atmosphere shroud. The DC plasma spray system, inert atmosphere shroud, and in-flight particle diagnostic sensor are detailed in Supporting Information S2a,b. It is anticipated that all inherent features of this technique, i.e., high quenching rate (∼106 K/s), extremely low particle residence time (in μs), and dense eddies in turbulent region, could help in exfoliation of graphite into graphene. We achieved graphene with high single-layer selectivity (∼85%), basal defect free (ID/IG = 0), and high purity (C/O ratio: 21.2; sp2 % = 95%) with very high production rate of 48 g/h on the laboratory scale. Furthermore, the exfoliated graphene performs well in applications that require high quality graphene in large quantities. Our single-layer graphene showed high Young’s modulus (850 GPa) and fine electrical conductivity under different bias voltage. The sheet resistance of the exfoliated graphene film was as low as 30 Ω/sq. In addition, the exfoliated graphene also demonstrated high specific capacitance value (375 F/g) and very low friction coefficient (COF = 0.03). In this study, we transformed a traditionally reserved technology for fabricating protective coatings into a protocol for ultrafast exfoliation of graphite to high quality graphene, which we believe could be a game- changer in this field. RESULTS AND DISCUSSION The graphite (detailed in Supporting Information S3) was directly introduced into the plasma plume without any pretreatment. We conducted multiple numbers of experiments with varying parameters (plasma power and primary gas flow https://dx.doi.org/10.1021/acsnano.0c09451 1776 ACS Nano 2021, 15, 1775−1784PDF Image | Production of High Quality Exfoliated Graphene

PDF Search Title:

Production of High Quality Exfoliated GrapheneOriginal File Name Searched:

Ultra-Fast-Chemical-Exfoliated-Graphene.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |