PDF Publication Title:

Text from PDF Page: 220

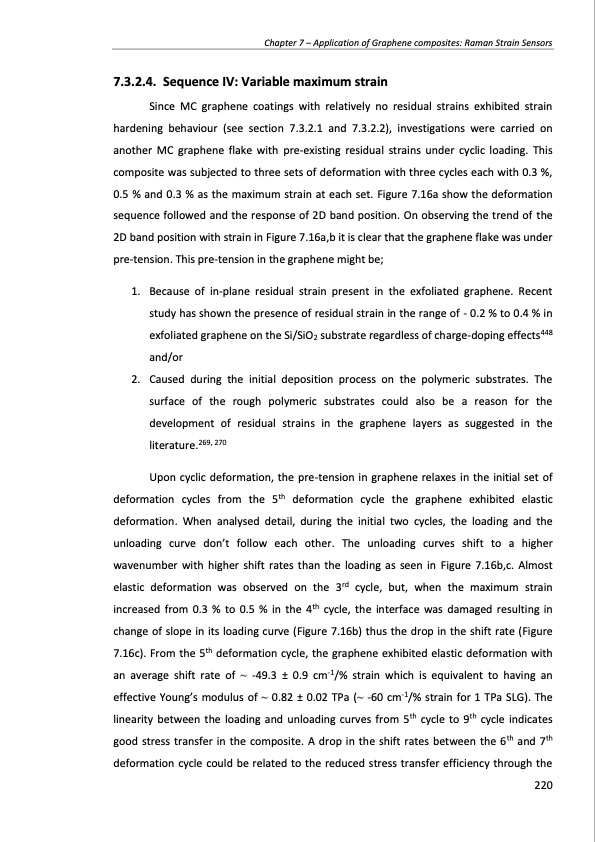

Chapter 7 – Application of Graphene composites: Raman Strain Sensors 7.3.2.4. Sequence IV: Variable maximum strain Since MC graphene coatings with relatively no residual strains exhibited strain hardening behaviour (see section 7.3.2.1 and 7.3.2.2), investigations were carried on another MC graphene flake with pre-existing residual strains under cyclic loading. This composite was subjected to three sets of deformation with three cycles each with 0.3 %, 0.5 % and 0.3 % as the maximum strain at each set. Figure 7.16a show the deformation sequence followed and the response of 2D band position. On observing the trend of the 2D band position with strain in Figure 7.16a,b it is clear that the graphene flake was under pre-tension. This pre-tension in the graphene might be; 1. Because of in-plane residual strain present in the exfoliated graphene. Recent study has shown the presence of residual strain in the range of - 0.2 % to 0.4 % in exfoliated graphene on the Si/SiO2 substrate regardless of charge-doping effects448 and/or 2. Caused during the initial deposition process on the polymeric substrates. The surface of the rough polymeric substrates could also be a reason for the development of residual strains in the graphene layers as suggested in the literature.269, 270 Upon cyclic deformation, the pre-tension in graphene relaxes in the initial set of deformation cycles from the 5th deformation cycle the graphene exhibited elastic deformation. When analysed detail, during the initial two cycles, the loading and the unloading curve don’t follow each other. The unloading curves shift to a higher wavenumber with higher shift rates than the loading as seen in Figure 7.16b,c. Almost elastic deformation was observed on the 3rd cycle, but, when the maximum strain increased from 0.3 % to 0.5 % in the 4th cycle, the interface was damaged resulting in change of slope in its loading curve (Figure 7.16b) thus the drop in the shift rate (Figure 7.16c). From the 5th deformation cycle, the graphene exhibited elastic deformation with an average shift rate of ~ -49.3 ± 0.9 cm-1/% strain which is equivalent to having an effective Young’s modulus of ~ 0.82 ± 0.02 TPa (~ -60 cm-1/% strain for 1 TPa SLG). The linearity between the loading and unloading curves from 5th cycle to 9th cycle indicates good stress transfer in the composite. A drop in the shift rates between the 6th and 7th deformation cycle could be related to the reduced stress transfer efficiency through the 220PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)