PDF Publication Title:

Text from PDF Page: 181

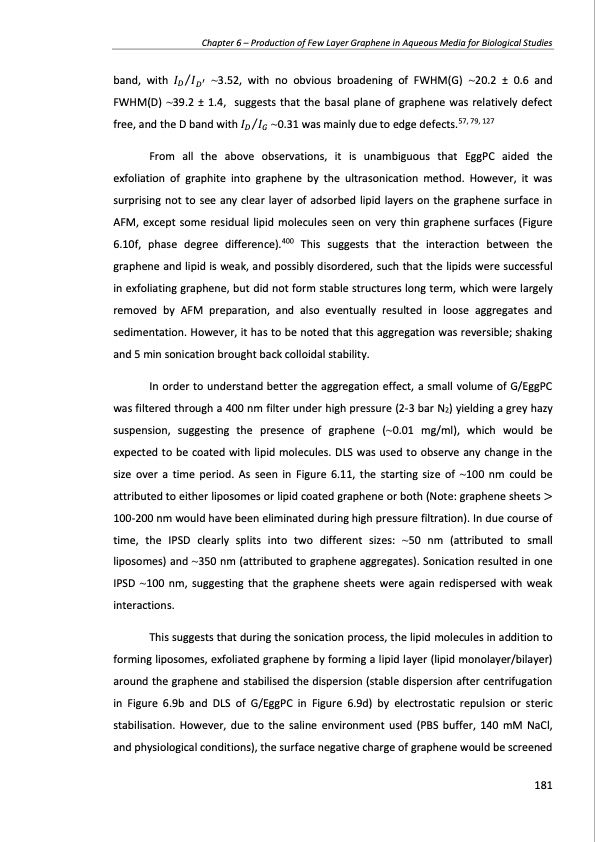

Chapter 6 – Production of Few Layer Graphene in Aqueous Media for Biological Studies band, with 𝐼𝐷⁄𝐼𝐷′ ~3.52, with no obvious broadening of FWHM(G) ~20.2 ± 0.6 and FWHM(D) ~39.2 ± 1.4, suggests that the basal plane of graphene was relatively defect free, and the D band with 𝐼𝐷⁄𝐼𝐺 ~0.31 was mainly due to edge defects.57, 79, 127 From all the above observations, it is unambiguous that EggPC aided the exfoliation of graphite into graphene by the ultrasonication method. However, it was surprising not to see any clear layer of adsorbed lipid layers on the graphene surface in AFM, except some residual lipid molecules seen on very thin graphene surfaces (Figure 6.10f, phase degree difference).400 This suggests that the interaction between the graphene and lipid is weak, and possibly disordered, such that the lipids were successful in exfoliating graphene, but did not form stable structures long term, which were largely removed by AFM preparation, and also eventually resulted in loose aggregates and sedimentation. However, it has to be noted that this aggregation was reversible; shaking and 5 min sonication brought back colloidal stability. In order to understand better the aggregation effect, a small volume of G/EggPC was filtered through a 400 nm filter under high pressure (2-3 bar N2) yielding a grey hazy suspension, suggesting the presence of graphene (~0.01 mg/ml), which would be expected to be coated with lipid molecules. DLS was used to observe any change in the size over a time period. As seen in Figure 6.11, the starting size of ~100 nm could be attributed to either liposomes or lipid coated graphene or both (Note: graphene sheets > 100-200 nm would have been eliminated during high pressure filtration). In due course of time, the IPSD clearly splits into two different sizes: ~50 nm (attributed to small liposomes) and ~350 nm (attributed to graphene aggregates). Sonication resulted in one IPSD ~100 nm, suggesting that the graphene sheets were again redispersed with weak interactions. This suggests that during the sonication process, the lipid molecules in addition to forming liposomes, exfoliated graphene by forming a lipid layer (lipid monolayer/bilayer) around the graphene and stabilised the dispersion (stable dispersion after centrifugation in Figure 6.9b and DLS of G/EggPC in Figure 6.9d) by electrostatic repulsion or steric stabilisation. However, due to the saline environment used (PBS buffer, 140 mM NaCl, and physiological conditions), the surface negative charge of graphene would be screened 181PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)