PDF Publication Title:

Text from PDF Page: 117

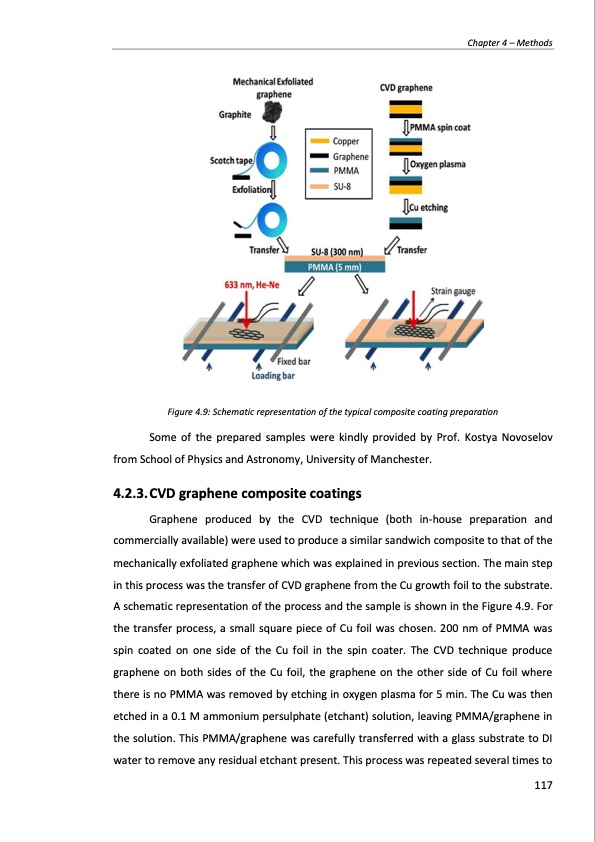

Chapter 4 – Methods Figure 4.9: Schematic representation of the typical composite coating preparation Some of the prepared samples were kindly provided by Prof. Kostya Novoselov from School of Physics and Astronomy, University of Manchester. 4.2.3.CVD graphene composite coatings Graphene produced by the CVD technique (both in-house preparation and commercially available) were used to produce a similar sandwich composite to that of the mechanically exfoliated graphene which was explained in previous section. The main step in this process was the transfer of CVD graphene from the Cu growth foil to the substrate. A schematic representation of the process and the sample is shown in the Figure 4.9. For the transfer process, a small square piece of Cu foil was chosen. 200 nm of PMMA was spin coated on one side of the Cu foil in the spin coater. The CVD technique produce graphene on both sides of the Cu foil, the graphene on the other side of Cu foil where there is no PMMA was removed by etching in oxygen plasma for 5 min. The Cu was then etched in a 0.1 M ammonium persulphate (etchant) solution, leaving PMMA/graphene in the solution. This PMMA/graphene was carefully transferred with a glass substrate to DI water to remove any residual etchant present. This process was repeated several times to 117PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)