PDF Publication Title:

Text from PDF Page: 116

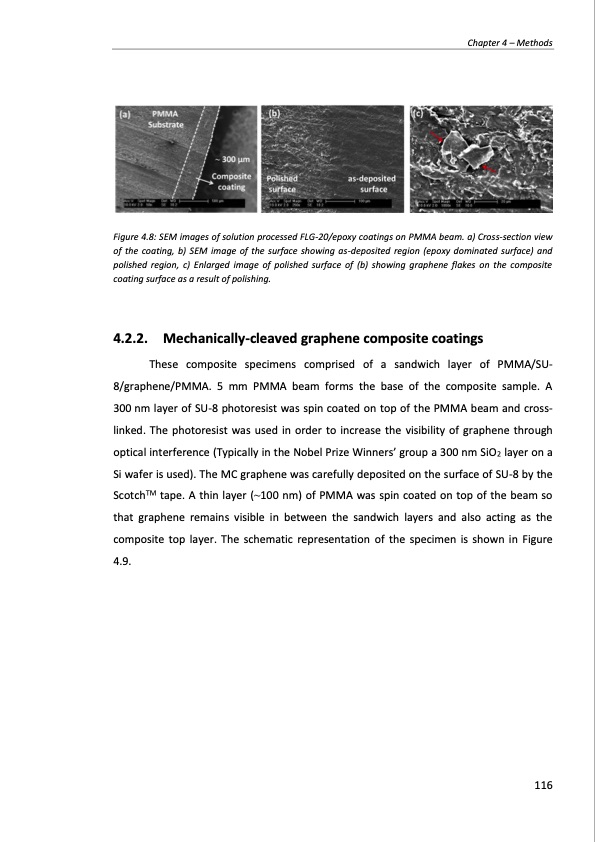

Chapter 4 – Methods Figure 4.8: SEM images of solution processed FLG-20/epoxy coatings on PMMA beam. a) Cross-section view of the coating, b) SEM image of the surface showing as-deposited region (epoxy dominated surface) and polished region, c) Enlarged image of polished surface of (b) showing graphene flakes on the composite coating surface as a result of polishing. 4.2.2. Mechanically-cleaved graphene composite coatings These composite specimens comprised of a sandwich layer of PMMA/SU- 8/graphene/PMMA. 5 mm PMMA beam forms the base of the composite sample. A 300 nm layer of SU-8 photoresist was spin coated on top of the PMMA beam and cross- linked. The photoresist was used in order to increase the visibility of graphene through optical interference (Typically in the Nobel Prize Winners’ group a 300 nm SiO2 layer on a Si wafer is used). The MC graphene was carefully deposited on the surface of SU-8 by the ScotchTM tape. A thin layer (~100 nm) of PMMA was spin coated on top of the beam so that graphene remains visible in between the sandwich layers and also acting as the composite top layer. The schematic representation of the specimen is shown in Figure 4.9. 116PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |