PDF Publication Title:

Text from PDF Page: 115

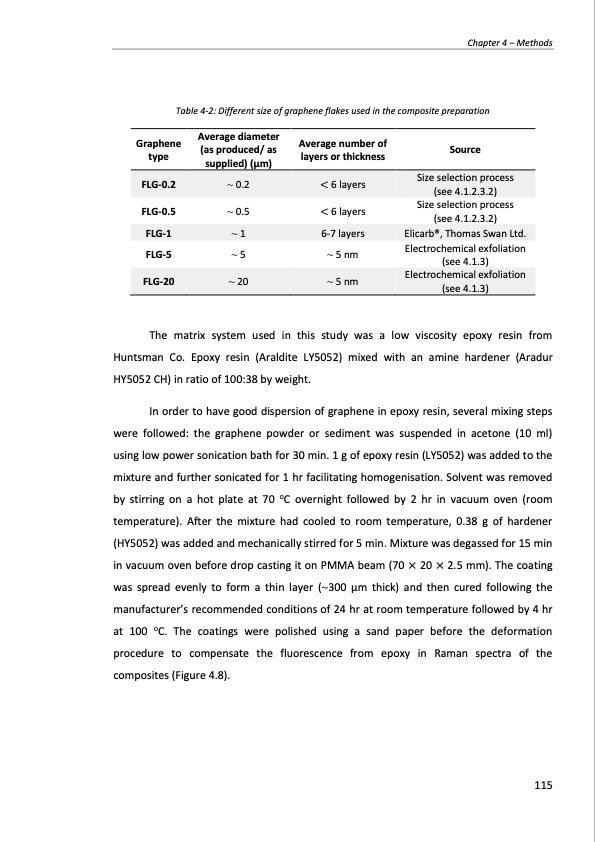

Table 4-2: Different size of graphene flakes used in the composite preparation Chapter 4 – Methods Graphene type FLG-0.5 FLG-5 Average diameter (as produced/ as supplied) (μm) ~ 0.5 ~ 5 Average number of layers or thickness < 6 layers ~ 5 nm Source Size selection process (see 4.1.2.3.2) Electrochemical exfoliation (see 4.1.3) FLG-0.2 ~ 0.2 < 6 layers Size selection process (see 4.1.2.3.2) FLG-1 ~ 1 6-7 layers Elicarb®, Thomas Swan Ltd. FLG-20 ~ 20 ~ 5 nm (see 4.1.3) The matrix system used in this study was a low viscosity epoxy resin from Huntsman Co. Epoxy resin (Araldite LY5052) mixed with an amine hardener (Aradur HY5052 CH) in ratio of 100:38 by weight. In order to have good dispersion of graphene in epoxy resin, several mixing steps were followed: the graphene powder or sediment was suspended in acetone (10 ml) using low power sonication bath for 30 min. 1 g of epoxy resin (LY5052) was added to the mixture and further sonicated for 1 hr facilitating homogenisation. Solvent was removed by stirring on a hot plate at 70 oC overnight followed by 2 hr in vacuum oven (room temperature). After the mixture had cooled to room temperature, 0.38 g of hardener (HY5052) was added and mechanically stirred for 5 min. Mixture was degassed for 15 min in vacuum oven before drop casting it on PMMA beam (70 × 20 × 2.5 mm). The coating was spread evenly to form a thin layer (~300 μm thick) and then cured following the manufacturer’s recommended conditions of 24 hr at room temperature followed by 4 hr at 100 oC. The coatings were polished using a sand paper before the deformation procedure to compensate the fluorescence from epoxy in Raman spectra of the composites (Figure 4.8). Electrochemical exfoliation 115PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)