PDF Publication Title:

Text from PDF Page: 106

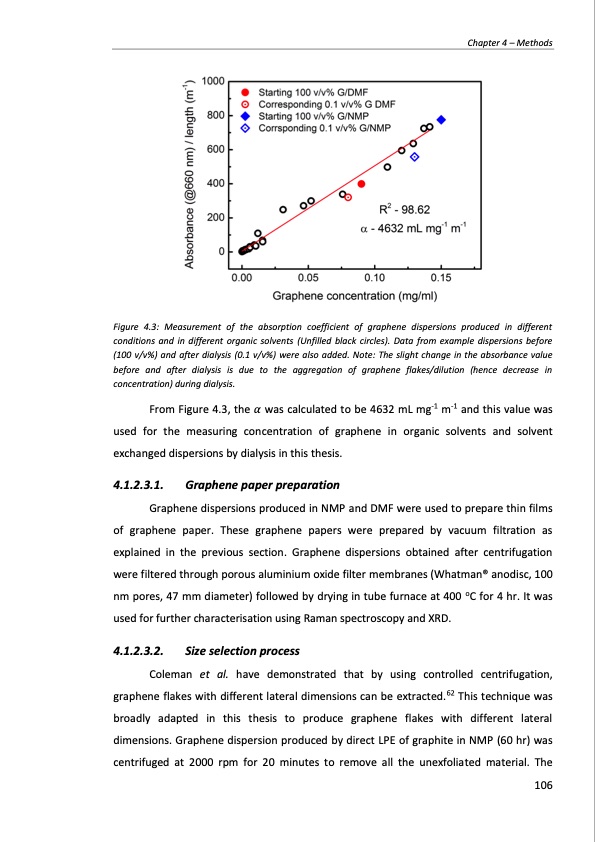

Chapter 4 – Methods Figure 4.3: Measurement of the absorption coefficient of graphene dispersions produced in different conditions and in different organic solvents (Unfilled black circles). Data from example dispersions before (100 v/v%) and after dialysis (0.1 v/v%) were also added. Note: The slight change in the absorbance value before and after dialysis is due to the aggregation of graphene flakes/dilution (hence decrease in concentration) during dialysis. From Figure 4.3, the 𝛼 was calculated to be 4632 mL mg-1 m-1 and this value was used for the measuring concentration of graphene in organic solvents and solvent exchanged dispersions by dialysis in this thesis. 4.1.2.3.1. Graphene paper preparation Graphene dispersions produced in NMP and DMF were used to prepare thin films of graphene paper. These graphene papers were prepared by vacuum filtration as explained in the previous section. Graphene dispersions obtained after centrifugation were filtered through porous aluminium oxide filter membranes (Whatman® anodisc, 100 nm pores, 47 mm diameter) followed by drying in tube furnace at 400 oC for 4 hr. It was used for further characterisation using Raman spectroscopy and XRD. 4.1.2.3.2. Size selection process Coleman et al. have demonstrated that by using controlled centrifugation, graphene flakes with different lateral dimensions can be extracted.62 This technique was broadly adapted in this thesis to produce graphene flakes with different lateral dimensions. Graphene dispersion produced by direct LPE of graphite in NMP (60 hr) was centrifuged at 2000 rpm for 20 minutes to remove all the unexfoliated material. The 106PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)