PDF Publication Title:

Text from PDF Page: 107

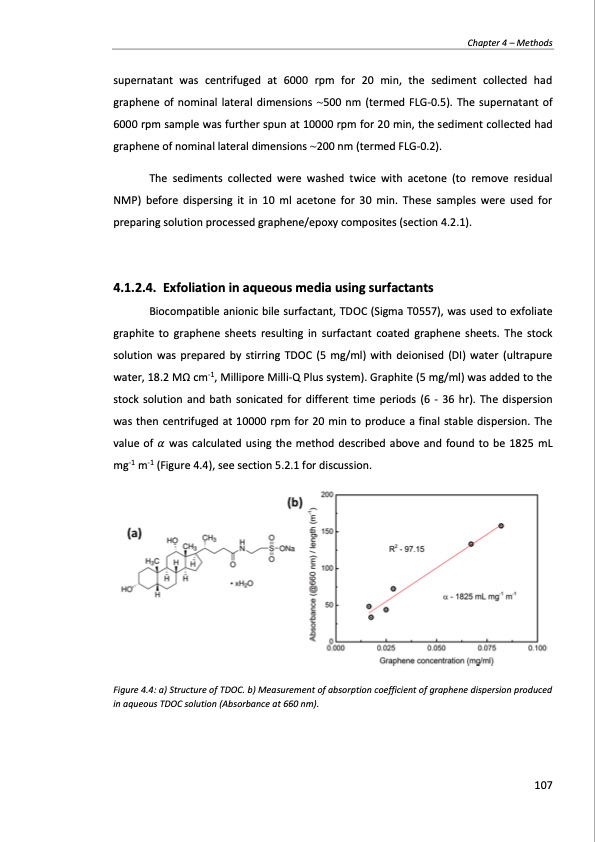

supernatant was centrifuged at 6000 rpm for 20 min, the sediment collected had graphene of nominal lateral dimensions ~500 nm (termed FLG-0.5). The supernatant of 6000 rpm sample was further spun at 10000 rpm for 20 min, the sediment collected had graphene of nominal lateral dimensions ~200 nm (termed FLG-0.2). The sediments collected were washed twice with acetone (to remove residual NMP) before dispersing it in 10 ml acetone for 30 min. These samples were used for preparing solution processed graphene/epoxy composites (section 4.2.1). 4.1.2.4. Exfoliation in aqueous media using surfactants Biocompatible anionic bile surfactant, TDOC (Sigma T0557), was used to exfoliate graphite to graphene sheets resulting in surfactant coated graphene sheets. The stock solution was prepared by stirring TDOC (5 mg/ml) with deionised (DI) water (ultrapure water, 18.2 MΩ cm-1, Millipore Milli-Q Plus system). Graphite (5 mg/ml) was added to the stock solution and bath sonicated for different time periods (6 - 36 hr). The dispersion was then centrifuged at 10000 rpm for 20 min to produce a final stable dispersion. The value of 𝛼 was calculated using the method described above and found to be 1825 mL mg-1 m-1 (Figure 4.4), see section 5.2.1 for discussion. Figure 4.4: a) Structure of TDOC. b) Measurement of absorption coefficient of graphene dispersion produced in aqueous TDOC solution (Absorbance at 660 nm). Chapter 4 – Methods 107PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |