PDF Publication Title:

Text from PDF Page: 059

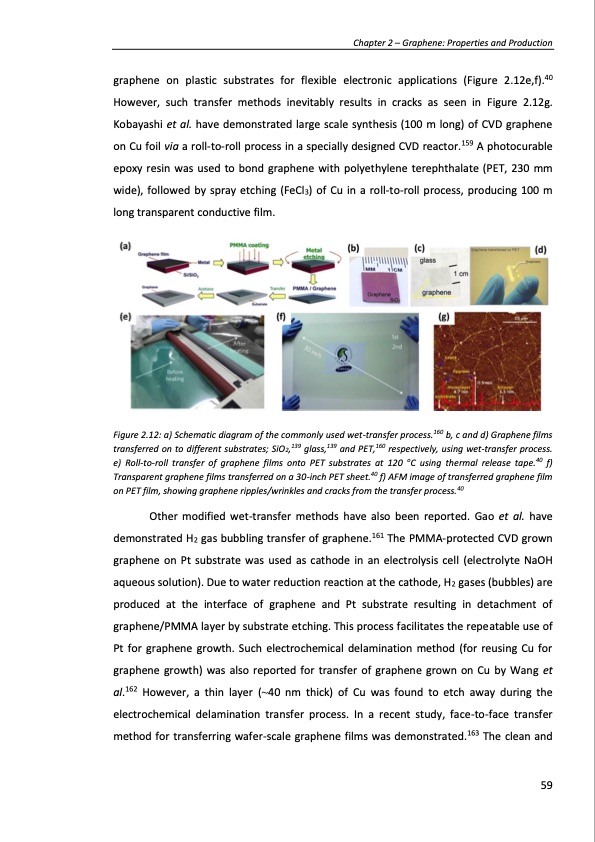

graphene on plastic substrates for flexible electronic applications (Figure 2.12e,f).40 However, such transfer methods inevitably results in cracks as seen in Figure 2.12g. Kobayashi et al. have demonstrated large scale synthesis (100 m long) of CVD graphene on Cu foil via a roll-to-roll process in a specially designed CVD reactor.159 A photocurable epoxy resin was used to bond graphene with polyethylene terephthalate (PET, 230 mm wide), followed by spray etching (FeCl3) of Cu in a roll-to-roll process, producing 100 m long transparent conductive film. Figure 2.12: a) Schematic diagram of the commonly used wet-transfer process.160 b, c and d) Graphene films transferred on to different substrates; SiO2,139 glass,139 and PET,160 respectively, using wet-transfer process. e) Roll-to-roll transfer of graphene films onto PET substrates at 120 oC using thermal release tape.40 f) Transparent graphene films transferred on a 30-inch PET sheet.40 f) AFM image of transferred graphene film on PET film, showing graphene ripples/wrinkles and cracks from the transfer process.40 Other modified wet-transfer methods have also been reported. Gao et al. have demonstrated H2 gas bubbling transfer of graphene.161 The PMMA-protected CVD grown graphene on Pt substrate was used as cathode in an electrolysis cell (electrolyte NaOH aqueous solution). Due to water reduction reaction at the cathode, H2 gases (bubbles) are produced at the interface of graphene and Pt substrate resulting in detachment of graphene/PMMA layer by substrate etching. This process facilitates the repeatable use of Pt for graphene growth. Such electrochemical delamination method (for reusing Cu for graphene growth) was also reported for transfer of graphene grown on Cu by Wang et al.162 However, a thin layer (~40 nm thick) of Cu was found to etch away during the electrochemical delamination transfer process. In a recent study, face-to-face transfer method for transferring wafer-scale graphene films was demonstrated.163 The clean and Chapter 2 – Graphene: Properties and Production 59PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)