PDF Publication Title:

Text from PDF Page: 056

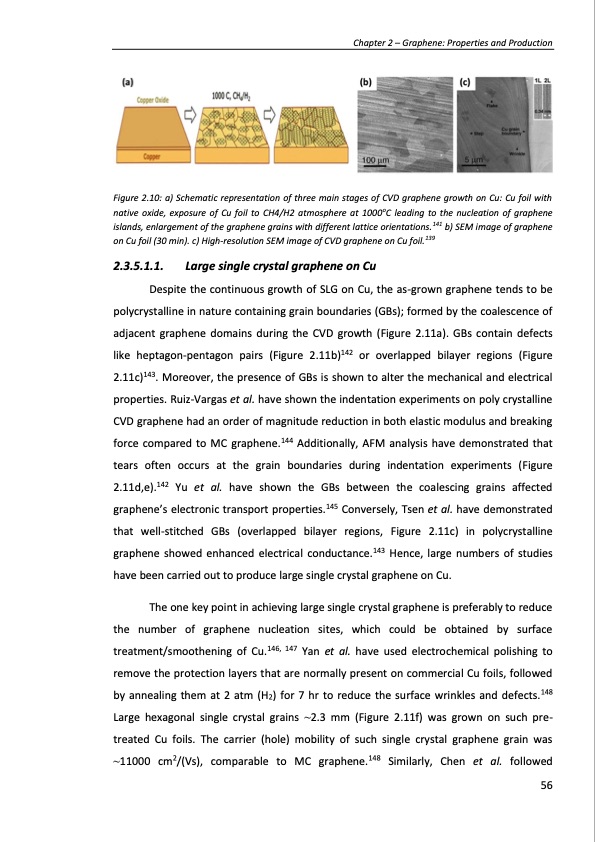

Chapter 2 – Graphene: Properties and Production Figure 2.10: a) Schematic representation of three main stages of CVD graphene growth on Cu: Cu foil with native oxide, exposure of Cu foil to CH4/H2 atmosphere at 1000oC leading to the nucleation of graphene islands, enlargement of the graphene grains with different lattice orientations.141 b) SEM image of graphene on Cu foil (30 min). c) High-resolution SEM image of CVD graphene on Cu foil.139 2.3.5.1.1. Large single crystal graphene on Cu Despite the continuous growth of SLG on Cu, the as-grown graphene tends to be polycrystalline in nature containing grain boundaries (GBs); formed by the coalescence of adjacent graphene domains during the CVD growth (Figure 2.11a). GBs contain defects like heptagon-pentagon pairs (Figure 2.11b)142 or overlapped bilayer regions (Figure 2.11c)143. Moreover, the presence of GBs is shown to alter the mechanical and electrical properties. Ruiz-Vargas et al. have shown the indentation experiments on poly crystalline CVD graphene had an order of magnitude reduction in both elastic modulus and breaking force compared to MC graphene.144 Additionally, AFM analysis have demonstrated that tears often occurs at the grain boundaries during indentation experiments (Figure 2.11d,e).142 Yu et al. have shown the GBs between the coalescing grains affected graphene’s electronic transport properties.145 Conversely, Tsen et al. have demonstrated that well-stitched GBs (overlapped bilayer regions, Figure 2.11c) in polycrystalline graphene showed enhanced electrical conductance.143 Hence, large numbers of studies have been carried out to produce large single crystal graphene on Cu. The one key point in achieving large single crystal graphene is preferably to reduce the number of graphene nucleation sites, which could be obtained by surface treatment/smoothening of Cu.146, 147 Yan et al. have used electrochemical polishing to remove the protection layers that are normally present on commercial Cu foils, followed by annealing them at 2 atm (H2) for 7 hr to reduce the surface wrinkles and defects.148 Large hexagonal single crystal grains ~2.3 mm (Figure 2.11f) was grown on such pre- treated Cu foils. The carrier (hole) mobility of such single crystal graphene grain was ~11000 cm2/(Vs), comparable to MC graphene.148 Similarly, Chen et al. followed 56PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |