PDF Publication Title:

Text from PDF Page: 036

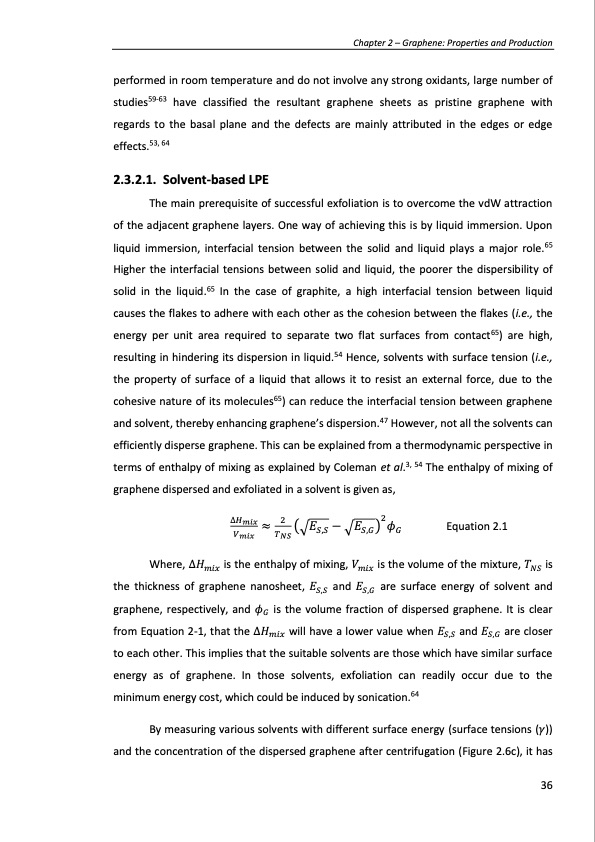

performed in room temperature and do not involve any strong oxidants, large number of studies59-63 have classified the resultant graphene sheets as pristine graphene with regards to the basal plane and the defects are mainly attributed in the edges or edge effects.53, 64 2.3.2.1. Solvent-based LPE The main prerequisite of successful exfoliation is to overcome the vdW attraction of the adjacent graphene layers. One way of achieving this is by liquid immersion. Upon liquid immersion, interfacial tension between the solid and liquid plays a major role.65 Higher the interfacial tensions between solid and liquid, the poorer the dispersibility of solid in the liquid.65 In the case of graphite, a high interfacial tension between liquid causes the flakes to adhere with each other as the cohesion between the flakes (i.e., the energy per unit area required to separate two flat surfaces from contact65) are high, resulting in hindering its dispersion in liquid.54 Hence, solvents with surface tension (i.e., the property of surface of a liquid that allows it to resist an external force, due to the cohesive nature of its molecules65) can reduce the interfacial tension between graphene and solvent, thereby enhancing graphene’s dispersion.47 However, not all the solvents can efficiently disperse graphene. This can be explained from a thermodynamic perspective in terms of enthalpy of mixing as explained by Coleman et al.3, 54 The enthalpy of mixing of graphene dispersed and exfoliated in a solvent is given as, ∆𝐻𝑚𝑖𝑥 ≈ 2 (√𝐸𝑆,𝑆 − √𝐸𝑆,𝐺)2𝜙𝐺 Equation 2.1 𝑉𝑚𝑖𝑥 𝑇𝑁𝑆 Where, ∆𝐻𝑚𝑖𝑥 is the enthalpy of mixing, 𝑉𝑚𝑖𝑥 is the volume of the mixture, 𝑇𝑁𝑆 is the thickness of graphene nanosheet, 𝐸𝑆,𝑆 and 𝐸𝑆,𝐺 are surface energy of solvent and graphene, respectively, and 𝜙𝐺 is the volume fraction of dispersed graphene. It is clear from Equation 2-1, that the ∆𝐻𝑚𝑖𝑥 will have a lower value when 𝐸𝑆,𝑆 and 𝐸𝑆,𝐺 are closer to each other. This implies that the suitable solvents are those which have similar surface energy as of graphene. In those solvents, exfoliation can readily occur due to the minimum energy cost, which could be induced by sonication.64 By measuring various solvents with different surface energy (surface tensions (𝛾)) and the concentration of the dispersed graphene after centrifugation (Figure 2.6c), it has Chapter 2 – Graphene: Properties and Production 36PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com (Standard Web Page)