PDF Publication Title:

Text from PDF Page: 003

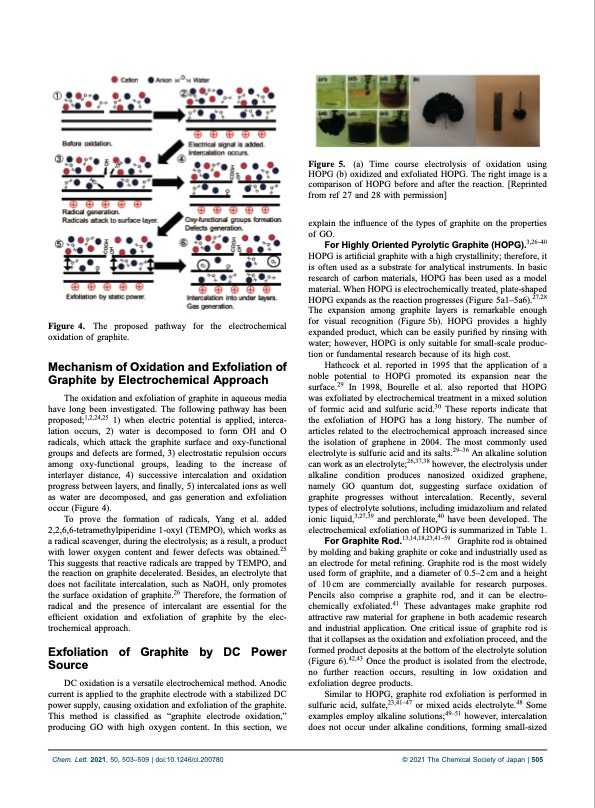

Figure 4. The proposed pathway for the electrochemical oxidation of graphite. Mechanism of Oxidation and Exfoliation of Graphite by Electrochemical Approach The oxidation and exfoliation of graphite in aqueous media have long been investigated. The following pathway has been proposed;1,2,24,25 1) when electric potential is applied, interca- lation occurs, 2) water is decomposed to form OH and O radicals, which attack the graphite surface and oxy-functional groups and defects are formed, 3) electrostatic repulsion occurs among oxy-functional groups, leading to the increase of interlayer distance, 4) successive intercalation and oxidation progress between layers, and finally, 5) intercalated ions as well as water are decomposed, and gas generation and exfoliation occur (Figure 4). To prove the formation of radicals, Yang et al. added 2,2,6,6-tetramethylpiperidine 1-oxyl (TEMPO), which works as a radical scavenger, during the electrolysis; as a result, a product with lower oxygen content and fewer defects was obtained.25 This suggests that reactive radicals are trapped by TEMPO, and the reaction on graphite decelerated. Besides, an electrolyte that does not facilitate intercalation, such as NaOH, only promotes the surface oxidation of graphite.26 Therefore, the formation of radical and the presence of intercalant are essential for the efficient oxidation and exfoliation of graphite by the elec- trochemical approach. Exfoliation of Graphite by DC Power Source DC oxidation is a versatile electrochemical method. Anodic current is applied to the graphite electrode with a stabilized DC power supply, causing oxidation and exfoliation of the graphite. This method is classified as “graphite electrode oxidation,” producing GO with high oxygen content. In this section, we Figure 5. (a) Time course electrolysis of oxidation using HOPG (b) oxidized and exfoliated HOPG. The right image is a comparison of HOPG before and after the reaction. [Reprinted from ref 27 and 28 with permission] explain the influence of the types of graphite on the properties of GO. For Highly Oriented Pyrolytic Graphite (HOPG).3,2640 HOPG is artificial graphite with a high crystallinity; therefore, it is often used as a substrate for analytical instruments. In basic research of carbon materials, HOPG has been used as a model material. When HOPG is electrochemically treated, plate-shaped HOPG expands as the reaction progresses (Figure 5a15a6).27,28 The expansion among graphite layers is remarkable enough for visual recognition (Figure 5b). HOPG provides a highly expanded product, which can be easily purified by rinsing with water; however, HOPG is only suitable for small-scale produc- tion or fundamental research because of its high cost. Hathcock et al. reported in 1995 that the application of a noble potential to HOPG promoted its expansion near the surface.29 In 1998, Bourelle et al. also reported that HOPG was exfoliated by electrochemical treatment in a mixed solution of formic acid and sulfuric acid.30 These reports indicate that the exfoliation of HOPG has a long history. The number of articles related to the electrochemical approach increased since the isolation of graphene in 2004. The most commonly used electrolyte is sulfuric acid and its salts.2936 An alkaline solution can work as an electrolyte;26,37,38 however, the electrolysis under alkaline condition produces nanosized oxidized graphene, namely GO quantum dot, suggesting surface oxidation of graphite progresses without intercalation. Recently, several types of electrolyte solutions, including imidazolium and related ionic liquid,3,27,39 and perchlorate,40 have been developed. The electrochemical exfoliation of HOPG is summarized in Table 1. For Graphite Rod.13,14,18,23,4159 Graphite rod is obtained by molding and baking graphite or coke and industrially used as an electrode for metal refining. Graphite rod is the most widely used form of graphite, and a diameter of 0.52 cm and a height of 10cm are commercially available for research purposes. Pencils also comprise a graphite rod, and it can be electro- chemically exfoliated.41 These advantages make graphite rod attractive raw material for graphene in both academic research and industrial application. One critical issue of graphite rod is that it collapses as the oxidation and exfoliation proceed, and the formed product deposits at the bottom of the electrolyte solution (Figure 6).42,43 Once the product is isolated from the electrode, no further reaction occurs, resulting in low oxidation and exfoliation degree products. Similar to HOPG, graphite rod exfoliation is performed in sulfuric acid, sulfate,23,4147 or mixed acids electrolyte.48 Some examples employ alkaline solutions;4951 however, intercalation does not occur under alkaline conditions, forming small-sized Chem. Lett. 2021, 50, 503–509 | doi:10.1246/cl.200780 © 2021 The Chemical Society of Japan | 505PDF Image | Electrochemical Production of Graphene Analogs

PDF Search Title:

Electrochemical Production of Graphene AnalogsOriginal File Name Searched:

cl-200780.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |