PDF Publication Title:

Text from PDF Page: 001

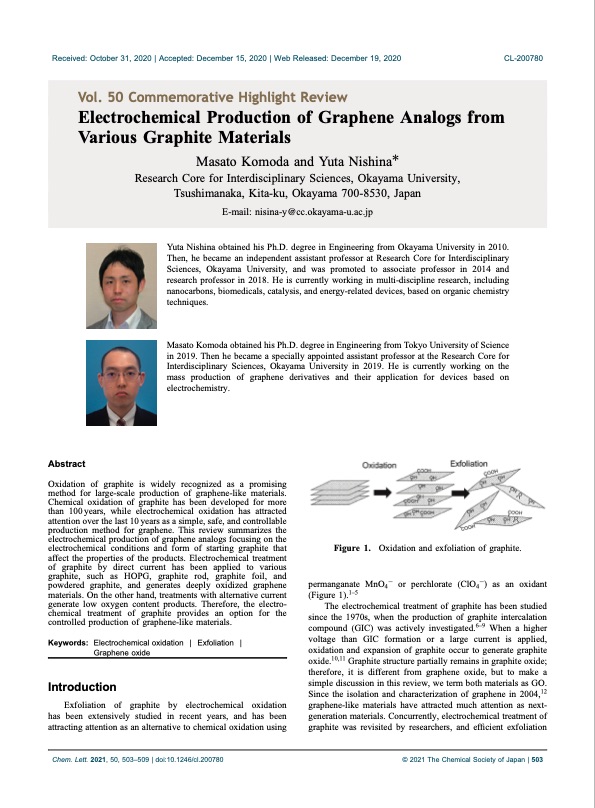

Received: October 31, 2020 | Accepted: December 15, 2020 | Web Released: December 19, 2020 CL-200780 Vol. 50 Commemorative Highlight Review Electrochemical Production of Graphene Analogs from Various Graphite Materials Masato Komoda and Yuta Nishina* Research Core for Interdisciplinary Sciences, Okayama University, Tsushimanaka, Kita-ku, Okayama 700-8530, Japan E-mail: nisina-y@cc.okayama-u.ac.jp Yuta Nishina obtained his Ph.D. degree in Engineering from Okayama University in 2010. Then, he became an independent assistant professor at Research Core for Interdisciplinary Sciences, Okayama University, and was promoted to associate professor in 2014 and research professor in 2018. He is currently working in multi-discipline research, including nanocarbons, biomedicals, catalysis, and energy-related devices, based on organic chemistry techniques. Masato Komoda obtained his Ph.D. degree in Engineering from Tokyo University of Science in 2019. Then he became a specially appointed assistant professor at the Research Core for Interdisciplinary Sciences, Okayama University in 2019. He is currently working on the mass production of graphene derivatives and their application for devices based on electrochemistry. Abstract Oxidation of graphite is widely recognized as a promising method for large-scale production of graphene-like materials. Chemical oxidation of graphite has been developed for more than 100years, while electrochemical oxidation has attracted attention over the last 10 years as a simple, safe, and controllable production method for graphene. This review summarizes the electrochemical production of graphene analogs focusing on the electrochemical conditions and form of starting graphite that affect the properties of the products. Electrochemical treatment of graphite by direct current has been applied to various graphite, such as HOPG, graphite rod, graphite foil, and powdered graphite, and generates deeply oxidized graphene materials. On the other hand, treatments with alternative current generate low oxygen content products. Therefore, the electro- chemical treatment of graphite provides an option for the controlled production of graphene-like materials. Keywords: Electrochemical oxidation | Exfoliation | Graphene oxide Introduction Exfoliation of graphite by electrochemical oxidation has been extensively studied in recent years, and has been attracting attention as an alternative to chemical oxidation using Figure 1. Oxidation and exfoliation of graphite. 11 or perchlorate (ClO4 ) as an oxidant permanganate MnO4 (Figure 1).15 The electrochemical treatment of graphite has been studied since the 1970s, when the production of graphite intercalation compound (GIC) was actively investigated.69 When a higher voltage than GIC formation or a large current is applied, oxidation and expansion of graphite occur to generate graphite oxide.10,11 Graphite structure partially remains in graphite oxide; therefore, it is different from graphene oxide, but to make a simple discussion in this review, we term both materials as GO. Since the isolation and characterization of graphene in 2004,12 graphene-like materials have attracted much attention as next- generation materials. Concurrently, electrochemical treatment of graphite was revisited by researchers, and efficient exfoliation Chem. Lett. 2021, 50, 503–509 | doi:10.1246/cl.200780 © 2021 The Chemical Society of Japan | 503PDF Image | Electrochemical Production of Graphene Analogs

PDF Search Title:

Electrochemical Production of Graphene AnalogsOriginal File Name Searched:

cl-200780.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |