PDF Publication Title:

Text from PDF Page: 173

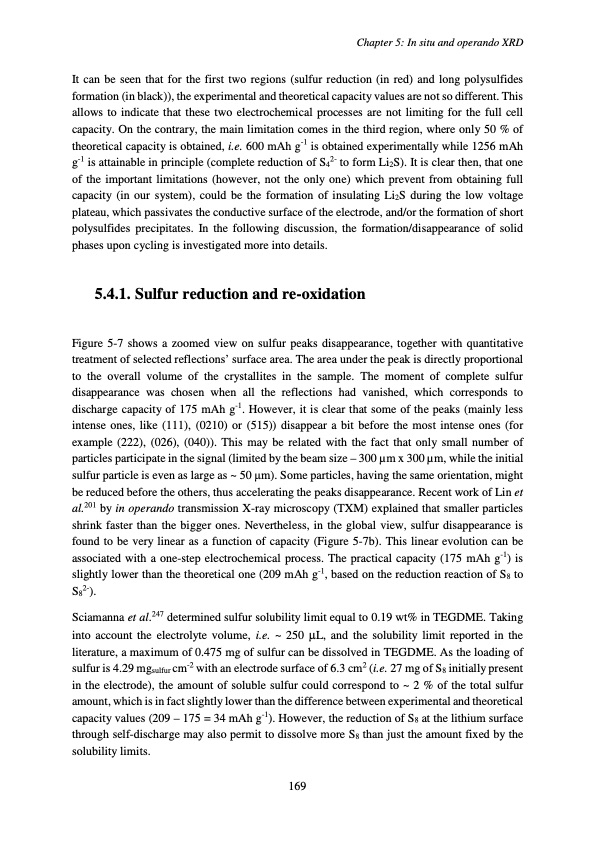

It can be seen that for the first two regions (sulfur reduction (in red) and long polysulfides formation (in black)), the experimental and theoretical capacity values are not so different. This allows to indicate that these two electrochemical processes are not limiting for the full cell capacity. On the contrary, the main limitation comes in the third region, where only 50 % of theoretical capacity is obtained, i.e. 600 mAh g-1 is obtained experimentally while 1256 mAh g-1 is attainable in principle (complete reduction of S42- to form Li2S). It is clear then, that one of the important limitations (however, not the only one) which prevent from obtaining full capacity (in our system), could be the formation of insulating Li2S during the low voltage plateau, which passivates the conductive surface of the electrode, and/or the formation of short polysulfides precipitates. In the following discussion, the formation/disappearance of solid phases upon cycling is investigated more into details. 5.4.1. Sulfur reduction and re-oxidation Figure 5-7 shows a zoomed view on sulfur peaks disappearance, together with quantitative treatment of selected reflections’ surface area. The area under the peak is directly proportional to the overall volume of the crystallites in the sample. The moment of complete sulfur disappearance was chosen when all the reflections had vanished, which corresponds to discharge capacity of 175 mAh g-1. However, it is clear that some of the peaks (mainly less intense ones, like (111), (0210) or (515)) disappear a bit before the most intense ones (for example (222), (026), (040)). This may be related with the fact that only small number of particles participate in the signal (limited by the beam size – 300 μm x 300 μm, while the initial sulfur particle is even as large as ~ 50 μm). Some particles, having the same orientation, might be reduced before the others, thus accelerating the peaks disappearance. Recent work of Lin et al.201 by in operando transmission X-ray microscopy (TXM) explained that smaller particles shrink faster than the bigger ones. Nevertheless, in the global view, sulfur disappearance is found to be very linear as a function of capacity (Figure 5-7b). This linear evolution can be associated with a one-step electrochemical process. The practical capacity (175 mAh g-1) is slightly lower than the theoretical one (209 mAh g-1, based on the reduction reaction of S8 to S82-). Sciamanna et al.247 determined sulfur solubility limit equal to 0.19 wt% in TEGDME. Taking into account the electrolyte volume, i.e. ~ 250 μL, and the solubility limit reported in the literature, a maximum of 0.475 mg of sulfur can be dissolved in TEGDME. As the loading of sulfur is 4.29 mgsulfur cm-2 with an electrode surface of 6.3 cm2 (i.e. 27 mg of S8 initially present in the electrode), the amount of soluble sulfur could correspond to ~ 2 % of the total sulfur amount, which is in fact slightly lower than the difference between experimental and theoretical capacity values (209 – 175 = 34 mAh g-1). However, the reduction of S8 at the lithium surface through self-discharge may also permit to dissolve more S8 than just the amount fixed by the solubility limits. 169 Chapter 5: In situ and operando XRDPDF Image | Accumulateur Lithium Soufre

PDF Search Title:

Accumulateur Lithium SoufreOriginal File Name Searched:

WALUS_2015_archivage.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |